What is a Vacuum Leak Tester?

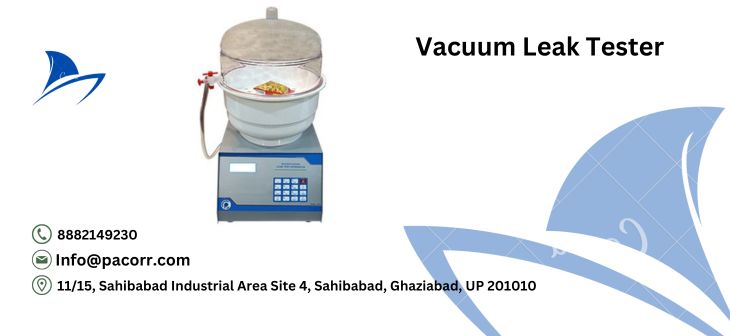

A Vacuum Leak Tester is a precision instrument designed to check for leaks in packaging materials by creating a vacuum environment. It is essential for industries where packaging integrity directly affects product quality, such as food and beverage, pharmaceuticals, and cosmetics.

The Vital Need for Vacuum Leak Tester

Vacuum Leak Tester stands at the forefront of quality control processes in industries where packaging integrity is non-negotiable. This testing method is pivotal for detecting leaks and ensuring that products reach consumers in the best possible condition. A leak in the packaging can lead to air ingress, microbial contamination, and ultimately, a compromised product. Thus, the role of the Vacuum Leak Tester extends beyond quality control; it is a guardian of brand reputation and consumer trust.

How the Vacuum Leak Tester Works

The principle behind the Vacuum Leak Tester is straightforward yet effective. It involves placing a packaged product inside a vacuum chamber and then drawing a vacuum. The presence of a leak is indicated by the inability of the package to maintain the vacuum over time. This method is both sensitive and versatile, capable of detecting even the smallest leaks that could lead to product spoilage.

What types of packages can be tested with this device?

Our Vacuum Leak Tester is versatile and can test a wide range of packaging types, including blisters, bottles, pouches, and trays. It's suitable for various materials like plastic, metal, glass, and cardboard, provided they can withstand the vacuum test without deformation.

Why is Vacuum Leak Tester important?

Vacuum Leak Tester is crucial for ensuring product safety, quality, and longevity. It helps in:

Preventing contamination by ensuring packaging is impermeable.

Guaranteeing the shelf life of perishable goods by maintaining a sterile environment.

Assuring consumer confidence in product integrity.

Can the Vacuum Leak Tester be used for quantitative analysis?

Yes, our Vacuum Leak Tester is not only capable of detecting the presence of leaks but also quantifying them. It measures the rate of vacuum loss, which can be correlated to the size of the leak, allowing for a more detailed analysis of packaging integrity.

How to ensure accurate results with the Vacuum Leak Tester?

For accurate results, ensure the test sample is properly sealed and placed correctly within the test chamber. The device settings should be adjusted according to the material type and thickness of the packaging being tested. Regular calibration and maintenance of the tester are also vital for consistent accuracy.

How to Ensure Accurate Testing Results?

For the most accurate results, ensure the packaging is correctly prepared and placed within the test chamber. Follow the manufacturer's guidelines for setting the appropriate vacuum level and test duration based on the packaging material and contents. Regular calibration and maintenance of the tester are also crucial to maintain its accuracy and reliability.

Can the Tester Quantify the Size of a Leak?

Yes, Pacorr's Vacuum Leak Tester are capable of not just detecting leaks but also quantifying them. This feature is invaluable for quality control, allowing you to determine the severity of a leak and make informed decisions on packaging materials and designs.

How Can I Purchase or Learn More About These Testers?

Interested in enhancing your quality control process with a Vacuum Leak Tester? Visit us at Pacorr.com. Here, you can explore our range of testers, request a quote, or contact our expert team for a detailed consultation on how our solutions can meet your specific needs.

Conclusion

In the competitive landscape of product manufacturing and distribution, ensuring the integrity of your packaging through Vacuum Leak Tester is not just an option—it’s a necessity. With Pacorr’s Vacuum Leak Tester, you gain a partner in your commitment to quality, safety, and customer satisfaction.

Read More: -

https://www.pacorr.com/product/vacuum-leak-tester-manufacturers-suppliers/

Comments