In industries like glass manufacturing, engineering, and materials research, detecting stress and defects in transparent materials is critical for safety and quality. One of the most effective instruments for this purpose is the Polariscope. Whether you are examining glass, plastics, or other transparent materials, a polariscope for glass or a polariscope strain viewer provides precise insights into internal stresses and structural integrity.

What is a Polariscope?

A Polariscope is an optical device used to observe and measure stress patterns in transparent materials. By using polarized light, it allows engineers and quality control specialists to visualize internal stresses that are invisible to the naked eye.

Polariscope technology is widely applied in industries such as:

- Glass manufacturing and quality control

- Plastic molding

- Engineering stress analysis

- Optical testing

How a Polariscope Works

The working principle of a polariscope is based on polarized light. When light passes through a stressed transparent material, it experiences a phenomenon called birefringence, which splits the light into two rays. These rays interfere and produce colorful patterns that reveal stress concentrations and defects.

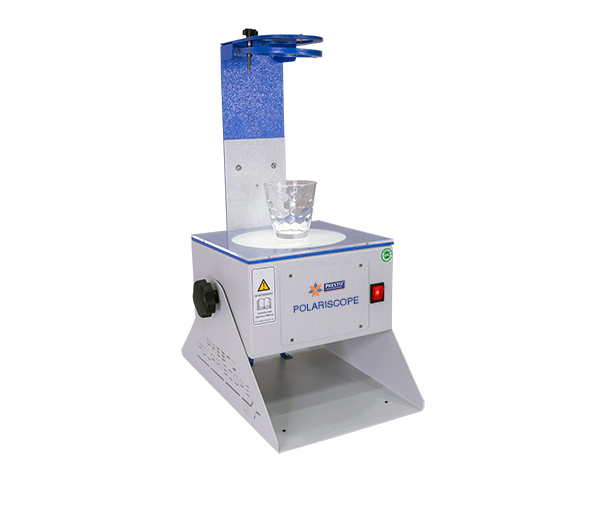

A typical polariscope for glass consists of:

- Light source – Provides uniform illumination

- Polarizing filters – Polarize the light to detect stress

- Analyzing filter – Helps observe stress patterns clearly

- Sample stage – Holds the material for examination

With these components, a polariscope strain viewer allows users to detect internal stresses, identify defects, and make informed quality control decisions.

Applications of a Polariscope

- Glass Manufacturing – Detects internal stresses in glass panes, bottles, and sheets to prevent cracks or breakage during handling.

- Plastic Industry – Evaluates stress in molded plastic components to ensure product durability.

- Engineering and Research – Used in labs to study material behavior under mechanical loads.

- Optical Component Testing – Ensures lenses, screens, and other optical devices meet high-quality standards.

By detecting stress early, a polariscope helps manufacturers reduce waste, improve safety, and maintain product quality.

Benefits of Using a Polariscope

- Accurate Stress Analysis – Reveals internal stresses that cannot be seen visually.

- Non-Destructive Testing – Allows materials to be tested without damage.

- Versatile Applications – Suitable for glass, plastics, and other transparent materials.

- Improved Product Quality – Identifies weak points and prevents product failures.

- Easy to Use – Modern polariscopes offer digital displays and user-friendly interfaces.

Polariscope Price Considerations

The polariscope price depends on several factors:

- Type – Simple manual polariscopes are more affordable, while digital or advanced models cost more.

- Size and Capacity – Larger stages and higher intensity lights may increase the price.

- Brand and Features – Reputed brands with advanced strain viewing technology often have higher costs.

- Accessories – Extra filters, digital displays, or software integration can influence pricing.

Investing in a high-quality polariscope ensures accurate stress detection and long-term reliability, making it a cost-effective solution for industries where material safety is crucial.

Conclusion

A polariscope or polariscope strain viewer is an indispensable tool for industries dealing with glass, plastics, and other transparent materials. By providing accurate stress analysis, it enhances product safety, quality, and reliability. Whether you are exploring a polariscope for glass or comparing options based on polariscope price, choosing the right instrument is vital for effective quality control and research applications.

Discover High-Quality Polariscope Instruments with Presto

Ensure your materials are stress-free and meet the highest quality standards with our advanced polariscope for glass and strain viewers.

📞 Call us at +91 9210 903 903

📧 Email: [email protected]

Upgrade your testing capabilities with Presto’s reliable polariscopes and achieve precise, non-destructive stress analysis for safer, more durable products!

Comments