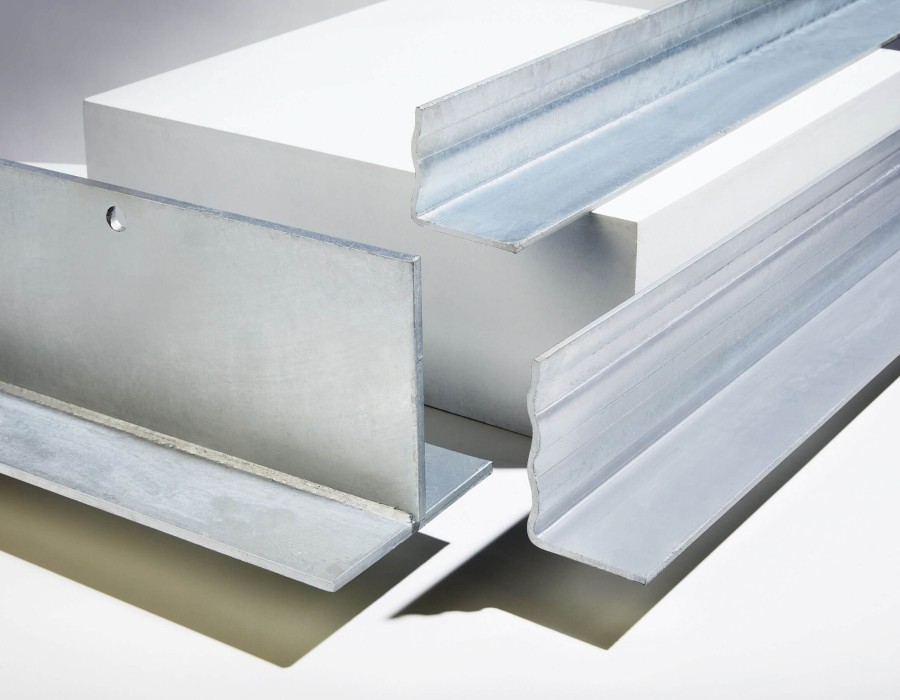

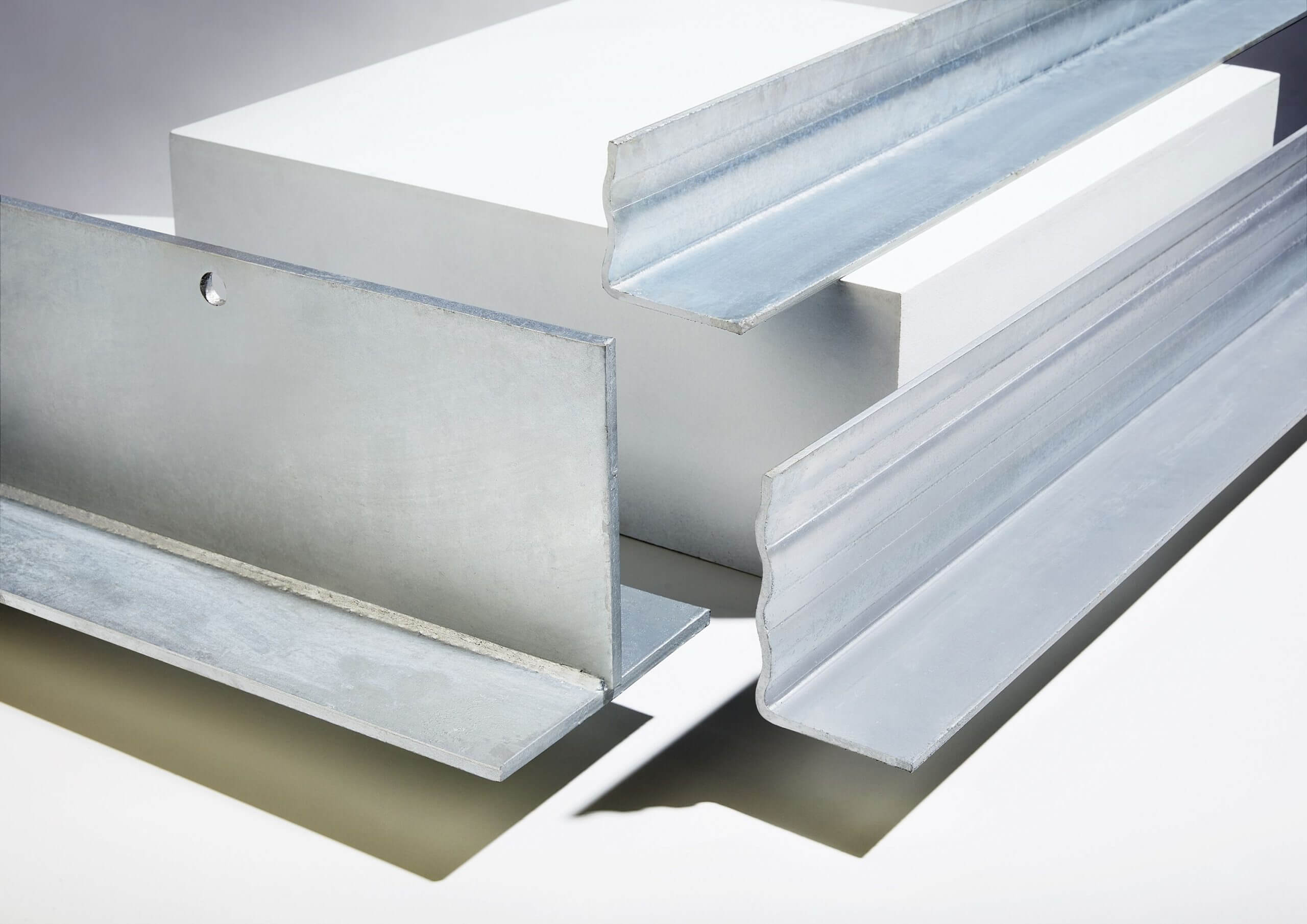

Lintels are an essential component in construction, providing crucial support to openings in walls, such as doors and windows. Among the various materials used for lintels, steel and galvanized steel stand out for their durability, strength, and versatility. In this article, we delve into the characteristics of Steel Lintels and galvanized lintels, highlighting their differences and benefits.

Lintels made of steel:

Steel lintels are renowned for their robustness and load-bearing capacity. Fabricated from high-quality steel, these lintels offer exceptional strength, making them ideal for supporting heavy loads over doorways, windows, and other openings in buildings. Steel's natural strength guarantees structural stability. Contributing to the longevity and stability of the overall construction.

One of the primary advantages of steel lintels is their versatility. They come in various shapes and sizes to suit different architectural designs and building requirements. Whether it's a straightforward beam or a more intricate arch, steel lintels can be customized to fit specific project needs, offering flexibility in design and construction.

Moreover, steel lintels are resistant to corrosion, which is a significant concern in areas exposed to extreme temperatures or damp environments. The protective coatings applied to steel lintels enhance their durability by preventing rust and corrosion, ensuring long-term performance and minimal maintenance requirements.

Galvanized Lintels:

Galvanized lintels take the strength and durability of steel lintels a step further by undergoing a galvanization process. This entails applying a zinc layer to the steel to offer additional protection against corrosion. The galvanization process creates a robust barrier between the steel and the elements, making Galv Lintels highly resistant to rust, corrosion, and other forms of deterioration.

The galvanized coating not only extends the lifespan of the lintels but also enhances their aesthetic appeal. Galvanized lintels maintain their appearance over time, retaining their sleek and polished finish even in challenging environments. This makes them an excellent choice for both interior and exterior applications where aesthetics play a significant role.

Furthermore, galvanized lintels offer superior performance in corrosive conditions like industrial settings or coastal areas where exposure to salt, moisture, and pollutants is prevalent. Even in the worst circumstances, the zinc coating serves as a sacrificial layer to prevent corrosion in the steel underneath.

Conclusion:

Both steel lintels and galvanized lintels offer unparalleled strength, durability, and versatility in construction projects. While steel lintels provide robust support and customization options, galvanized lintels go a step further by adding a protective layer against corrosion, ensuring long-lasting performance in diverse environments.

For high-quality steel lintels and galvanized lintels that meet rigorous standards of strength, durability, and corrosion resistance, visit galintel.com.au. With an extensive selection of goods designed to suit various construction needs, Galintel is your trusted partner for superior lintel solutions.

Comments