Safety First:

The primary objective of pallet rack inspection services is to ensure the safety of both personnel and inventory. Over time, pallet racks can experience structural damage due to factors such as impacts from forklifts, overloading, or general wear. Regular inspections help identify potential hazards before they escalate into serious accidents, preventing injuries to workers and minimizing the risk of damage to valuable stock.

Compliance with Regulations:

Occupational Safety and Health Administration (OSHA) and other regulatory bodies set strict guidelines for warehouse safety. Compliance with these regulations is not just a legal requirement but also a moral obligation to protect the well-being of employees. Pallet rack inspection services assist businesses in meeting these standards by thoroughly examining racks for any signs of damage or non-compliance. Failure to adhere to safety regulations can result in fines, legal consequences, and, most importantly, a compromised work environment.

Operational Efficiency:

Beyond safety considerations, pallet rack inspection services contribute to operational efficiency. Well-maintained and properly inspected racks ensure that the storage systems function optimally. Identifying and addressing issues promptly helps prevent disruptions to daily operations and reduces the likelihood of unexpected downtimes. This proactive approach to maintenance contributes to a smooth workflow, ultimately enhancing overall productivity.

Cost Savings:

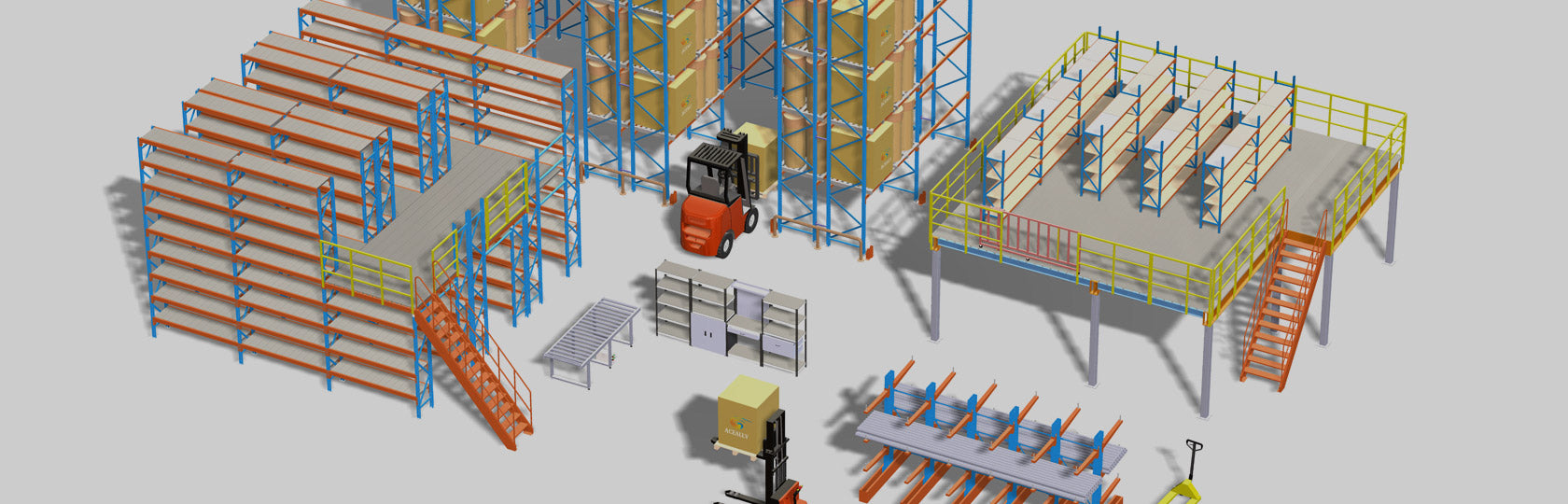

Investing in pallet rack inspection services is a strategic move that can lead to significant cost savings in the long run. By identifying and addressing potential issues early on, businesses can avoid expensive repairs or replacements that may be necessary if damage goes unnoticed. Additionally, a comprehensive inspection program can extend the lifespan of pallet racks, Pallet Racking Installation maximizing the return on investment for these critical storage solutions.

Customized Inspection Programs:

Pallet rack inspection services are not one-size-fits-all; they can be tailored to meet the specific needs of each warehouse or distribution center. These services typically involve trained professionals conducting thorough inspections, documenting findings, and providing detailed reports with recommendations for corrective actions. Regular inspections can be scheduled based on the intensity of warehouse activities and the type of inventory being stored.

.jpg)

Comments