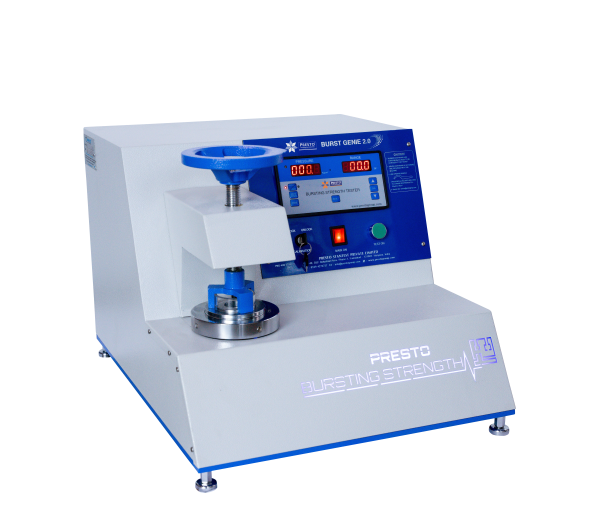

The bursting strength tester is an essential instrument for industries that rely on the quality and durability of packaging materials such as paper, cardboard, and corrugated boxes. This device evaluates the material's resistance to rupture under pressure, ensuring that products remain safe during storage and transportation. For manufacturers and suppliers, maintaining high packaging standards is critical, and the bursting strength tester plays a pivotal role in achieving this goal.

What is a Bursting Strength Tester?

A bursting strength tester measures the ability of packaging materials to withstand pressure without bursting. It applies hydraulic or pneumatic force to a sample until it ruptures, providing an accurate measure of the material's strength. This test is crucial for industries like food, pharmaceuticals, and e-commerce, where reliable packaging is a priority.

Advantages of Digital Bursting Strength Testers

A digital bursting strength tester offers advanced features for precise and efficient testing. Unlike manual models, digital testers provide automated calculations, user-friendly interfaces, and data storage capabilities. These benefits allow manufacturers to:

- Obtain consistent and accurate results.

- Save time with automated processes.

- Monitor trends with stored data for quality analysis.

Understanding Bursting Strength Tester Prices

The bursting strength tester price depends on several factors, including:

- Type of Tester: Digital models with advanced features are generally more expensive than manual versions.

- Build Quality: High-quality materials and robust construction contribute to higher costs but ensure durability.

- Brand and Manufacturer: Reputable manufacturers may charge a premium for their reliable and accurate testers.

While initial investment costs may vary, a high-quality tester offers long-term benefits by reducing packaging failures and enhancing customer satisfaction.

Choosing the Right Bursting Strength Tester Manufacturer

When selecting a bursting strength tester manufacturer, it’s important to prioritize quality, reliability, and customer support. Trusted manufacturers provide:

- Custom Solutions: Tailored testers to meet specific industry needs.

- High Accuracy: Ensuring compliance with international testing standards.

- Comprehensive Support: Maintenance, calibration, and troubleshooting services.

Why Invest in a Bursting Strength Tester?

- Enhanced Product Safety: Prevents packaging failures and ensures product integrity during shipping.

- Regulatory Compliance: Meets industry standards for packaging strength.

- Cost Efficiency: Reduces material wastage and product returns.

In conclusion, a bursting strength tester, whether digital or manual, is an invaluable tool for industries focused on packaging quality. By understanding factors like price and choosing a reliable manufacturer, businesses can ensure their products are protected, boosting efficiency and customer satisfaction.

Comments