Conically shaped Bin activator help move dry bulk materials out of hoppers or silos. Bin Activators have many industrial uses, including discharging dry solid products in powder or granular form from upstream equipment without them clumping together and preventing bridging or ratholing.

- An Activator of Bins

Bin activators are a specific kind of Bin discharger that shake up materials stuck in a hopper or bin, allowing them to go freely into the manufacturing process. Powdery or granular materials, for instance, might form arcs and bridges that prevent them from flowing uniformly, which can result in product loss or leakage.

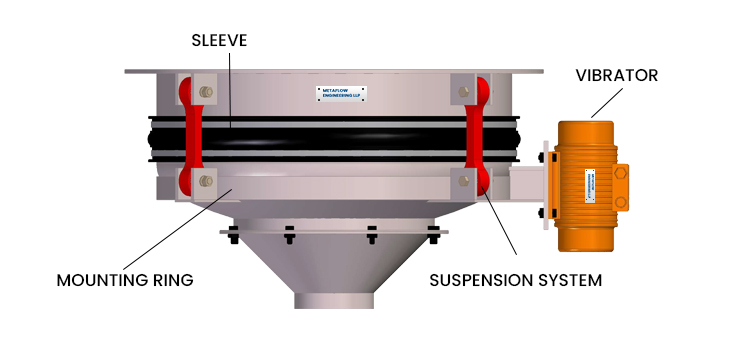

Bin activator use vibration to rouse the contents and encourage movement. They can be placed independently at the bottom of a silo, bin, or hopper. A vibrating cone receives the material and consistently releases the powder into the next process stage. Heavy-duty bin activators of stainless steel or other food-safe materials are readily available.

Advantages of bin openers

Various Bin discharger are available with several distinct dry bulk materials and storage vessel sizes. They offer a plethora of benefits to the end-user sectors. The following are just a few of the many uses for bin activators:

- Special spring suspensions ensure complete resistance to the dish head's vibrations.

- Inlet and outlet connections with flexible seals for added safety.

- High efficiency, leading to a reduced carbon footprint.

- Quick to install and requiring little care.

- Exceptional performance efficiency.

- A sealed housing for the motor.

- Guaranteed silent discharge.

Feeding device that vibrates

Manufacturers in various fields often look to Vibrating feeder to take the reins. The manual handling, weariness, and potential injury involved in moving thousands of things can be eliminated with this machinery. In addition, they're built with the operators' safety in mind. The pharmaceutical, automotive, electronic, cosmetic, food, and packaging sectors are just a few that employ Vibrating feeder to manage bulk materials. Vibratory feeders can handle various materials, from large chunks to finer particles. Machines like these are also used in the recycling of different materials, the production of paper and pulp, the processing of metals, the handling of dry bulk solids, and many more applications. Because of its design, technique, and utility adaptability, vibratory feeders can be used in various manufacturing setups.

Feeding Vibration Tube

Vibration tube feeders are utilised when bulks (powder or granular materials) need to be fed or dosed precisely, without any mechanical force operating directly on the bulk. The Vibrating tube feeder can be set up at the base of a silo or farther downstream in the bulk material processing system.

- How a Vibrating Screen Works

The gyratory motion is the foundation of the Vibrating screen's operation. The eccentric flywheel causes the sieve attached to the rubber attachment to spin around a stationary axis. As a result of the gyratory motion, the feed moves slightly upward and downward, making it tilted at an angle from the vertical. This tilting motion rotates clockwise.

Conclusion

Vibrations from bin activators help material flow from silos or hoppers. Material is moved with vibration and gravity in vibratory feeders. Vibration shifts the material in two directions determined by gravity: down or down and to one side.

Comments