The world of engineering and industrial machinery design has witnessed significant advancements over the years. Among the numerous mechanisms employed in gearbox services, double helical gearing stands out for its remarkable efficiency and torque-transmission capabilities. However, like all sophisticated systems, double helical gears are not exempt from potential challenges. One such critical aspect that demands attention is the influence of thermal growth on shaft vibration. This article delves into the intricate relationship between thermal growth and shaft vibration in double helical gearing, exploring the underlying mechanisms and the potential impact on machinery performance.

The Inner Workings of Double Helical Gearing

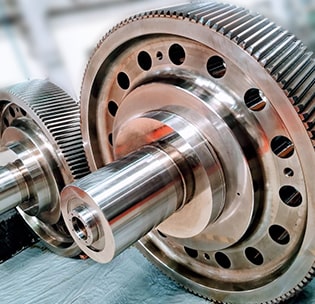

Before diving into the influence of thermal growth on shaft vibration, it is essential to grasp the fundamentals of double helical gearing. These gears are designed by the best gears manufacturers in India with two sets of teeth, inclined in opposite directions, resulting in improved load distribution and reduced noise compared to conventional single helical gears. The meshing of these double helical gears transfers power smoothly, making them ideal for high-torque applications. However, it is the dynamic nature of their design that renders them susceptible to certain operational challenges.

The Role of Couplings in Machinery

Couplings serve as vital components in many mechanical systems, linking two shafts to facilitate torque transmission. The primary purpose of couplings is to accommodate misalignments and reduce shock. It ensures smoother operation and prolongs the life of gears and other transmission elements. In this context, flexible couplings are commonly employed, which can absorb misalignment through their elastic properties.

Understanding Thermal Growth and Its Causes

Thermal growth is a phenomenon wherein mechanical components, including gears and couplings, undergo dimensional changes due to variations in temperature during operation. These temperature fluctuations cause the materials to expand or contract, resulting in alterations in the physical dimensions.

Several factors contribute to thermal growth, including ambient temperature changes; heat generated by friction during gear meshing, and power losses in bearings and windage loss within the system.

The accumulation of heat can significantly impact the overall machinery performance and lead to shaft vibration.

The Nexus between Thermal Growth and Shaft Vibration

Thermal growth affects shaft vibration in a complex way.

The gear and connected equipment shaft can expand during operation, changing the alignment between the shafts. Because of their elastic nature, flexible couplings are able to partially compensate for this misalignment.

A misalignment though gets accommodated by coupling and extent of misalignment always generates reaction load on double helical gearing.

Such reaction load coupled with axial thermal growth of entire train will cause axial pull / push on gears resulting in helix bound(lock) condition. Due to this Gear teeth become more stressed as the gears struggle to maintain a harmonious mesh between two helixes, causing shaft vibration.

This can culminate in excessive wear and fatigue, reducing the overall lifespan of the gear system and potentially causing unexpected breakdowns.

Identifying the Warning Signs

Detecting the early signs of thermal growth and shaft vibration is crucial for preventing catastrophic failures and minimizing downtime. Some common indicators include unusual noise/vibration during no load or low load operation and visible signs of localized tooth contact on gear teeth. Ensuring required load contact of gears using steel red / dykem gears during installation and commissioning can aid in identifying potential issues before they escalate into costly problems.

Mitigating the Impact of Coupling Thermal Growth on Shaft Vibration

Thermal growth of connected equipment, couplings and shafts can influence shaft vibration in several ways. During design stage, thermal growth both radial and axial of the entire train needs to be calculated and required corrections during installation by way of keeping alignment offset / coupling prestretch is essential to overcome effects of thermal growth. A routine maintenance program should include alignment checks, gear inspections, and load contact checks. Estimating and compensating thermal growth by keeping required misalignment and coupling pre stretch reduces uneven loading in double helical gears and its shaft vibrations.

Conclusion

In the world of double helical gearing, the intricate interplay between thermal growth and shaft vibration demands diligent attention. Contemporary gears manufacturers India must remain vigilant in detecting early warning signs and implementing effective mitigation strategies to ensure the smooth and reliable operation of machinery. By understanding the mechanisms behind thermal growth and its impact on shaft vibration, industries can uphold the efficiency and longevity of their critical mechanical systems, paving the way for a more productive and sustainable future

Comments