Introduction

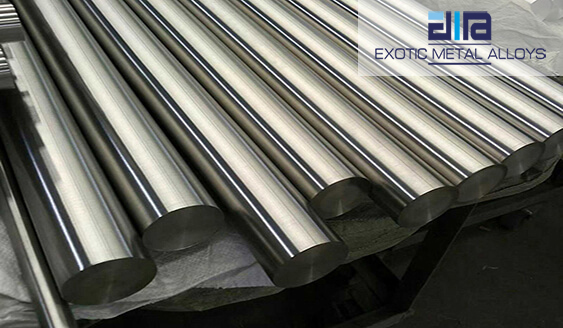

Incoloy 801 is a high-performance alloy known for its excellent strength, stability, and resistance to oxidation and carburization at elevated temperatures. In round bar form, Incoloy 801 is a versatile material widely used across various industries. This blog provides an in-depth look at Incoloy 801 Round Bar, its properties, applications, benefits, and key considerations for sourcing this advanced material.

What is Incoloy 801?

Incoloy 801 is a nickel-iron-chromium alloy designed to provide superior performance in high-temperature environments. It offers a combination of high strength and resistance to oxidation, carburization, and other forms of high-temperature corrosion. The alloy is particularly well-suited for use in applications requiring prolonged exposure to elevated temperatures.

Specifications of Incoloy 801 Round Bar

Specifications

:

ASTM B408, ASME SB408

Dimensions

:

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size

:

5 mm To 500 mm

Diameter

:

0.01 mm to 250 mm

Length

:

100 mm To 3000 mm Long & Above

Finish

:

Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Tolerance

:

H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements

Form

:

Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Key Properties of Incoloy 801 Round Bar

1. High Temperature Strength: Incoloy 801 maintains its mechanical strength and stability at temperatures up to 1100°C (2012°F), making it ideal for high-temperature applications.

2. Oxidation and Carburization Resistance: The alloy exhibits excellent resistance to oxidation and carburization, ensuring durability and longevity in harsh environments.

3. Corrosion Resistance: Incoloy 801 is resistant to a wide range of corrosive environments, including acidic and alkaline solutions.

4. Metallurgical Stability: The alloy maintains its structural integrity over prolonged exposure to high temperatures, reducing the risk of thermal fatigue and creep.

Applications of Incoloy 801 Round Bar

Due to its superior properties, Incoloy 801 Round Bar is used in various high-temperature and corrosive environments, including:

- Petrochemical and Refining: Ideal for furnace components, heat exchangers, and catalytic cracking units exposed to high temperatures and corrosive media.

- Power Generation: Used in steam generators, superheaters, and reheaters in both fossil fuel and nuclear power plants.

- Chemical Processing: Suitable for equipment handling corrosive chemicals at elevated temperatures, such as reactors, piping, and valves.

- Industrial Heating: Employed in heating elements, fixtures, and trays used in heat treatment and annealing processes.

- Aerospace: Utilized in components exposed to high thermal stresses, including gas turbine engines and afterburners.

Advantages of Using Incoloy 801 Round Bar

1. Enhanced Performance: Incoloy 801 provides superior mechanical properties at high temperatures, ensuring reliable performance in demanding applications.

2. Longevity: The alloy's resistance to oxidation, carburization, and corrosion extends the lifespan of components, reducing maintenance and replacement costs.

3. Versatility: Suitable for a wide range of high-temperature and corrosive environments, making it a versatile choice for various industries.

4. Fabrication: Incoloy 801 can be easily machined, welded, and formed, allowing for flexible manufacturing and design options.

Conclusion

Incoloy 801 Round Bar is a high-performance material that offers exceptional strength, oxidation resistance, and stability at high temperatures. By understanding its properties and applications, and by carefully selecting a reliable supplier, you can ensure you obtain the best quality materials for your projects. Incoloy 801 continues to be a trusted choice in challenging environments, providing long-lasting performance and reducing overall costs.

Comments