Centrifugal water pumps are indispensable tools in various industries, playing a pivotal role in fluid management systems worldwide. Whether in agriculture, manufacturing, or municipal water distribution, these devices offer efficient and reliable solutions for pumping water and other fluids. In this article, we delve into the mechanics, applications, and advantages of centrifugal water pumps, exploring how they contribute to enhancing productivity and sustainability across different sectors.

Understanding Centrifugal Water Pumps:

Centrifugal water pumps operate on the principle of centrifugal force to transfer fluids from one location to another. Unlike positive displacement pumps that use reciprocating or rotating mechanisms to move fluid, centrifugal pumps rely on the kinetic energy of the fluid to generate velocity and pressure. This process involves the conversion of rotational energy from an impeller into hydrodynamic energy, propelling the fluid through the pump's casing and discharge outlet.

Key Components and Working Mechanism:

At the heart of a centrifugal water pump lies the impeller, a rotating component with curved blades or vanes designed to accelerate the fluid. As the impeller spins, it creates a low-pressure zone at the center, drawing fluid into the pump through the suction inlet. The centrifugal force generated by the impeller's rotation then pushes the fluid outward, increasing its velocity and pressure before exiting through the discharge outlet. The pump casing, volute, and diffuser play crucial roles in directing and controlling the flow of fluid, ensuring efficient operation and minimal energy loss.

Applications Across Industries:

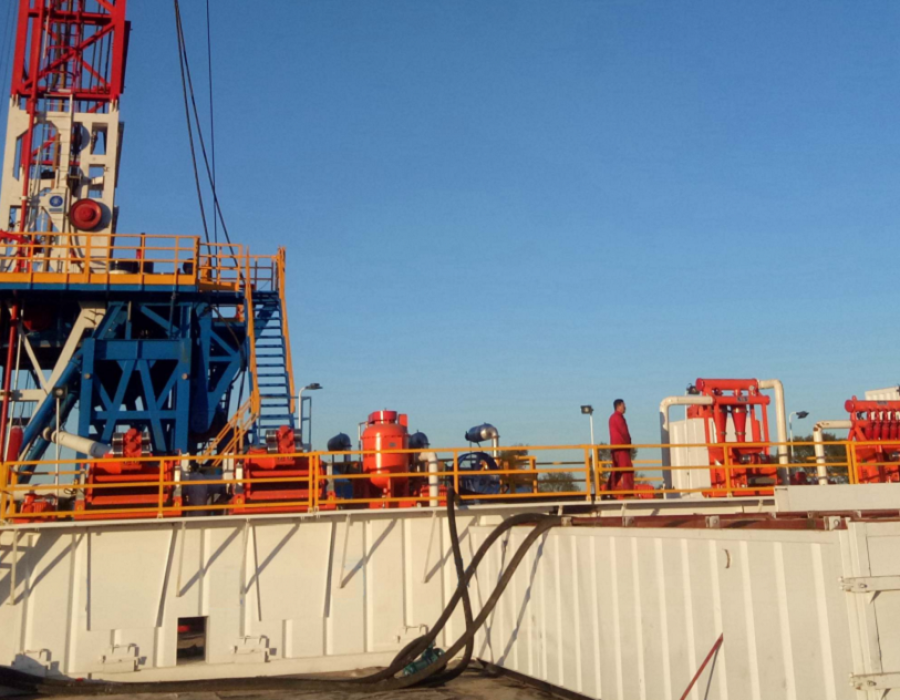

Centrifugal water pumps find extensive use across a wide range of industries and applications. In agriculture, these pumps are employed for irrigation, drainage, and water transfer, facilitating crop cultivation and land management practices. In manufacturing and construction, they play a vital role in coolant circulation, HVAC systems, and wastewater treatment processes. Municipalities rely on centrifugal pumps for water supply and distribution networks, firefighting, and sewage handling, ensuring public health and safety. Moreover, these pumps are integral to marine, mining, oil and gas, and power generation sectors, supporting critical operations and infrastructure.

Advantages and Benefits:

The widespread adoption of centrifugal water pump can be attributed to several key advantages they offer:

- High Efficiency: Centrifugal pumps are known for their efficiency in converting input power into fluid flow, minimizing energy consumption and operational costs.

- Versatility: These pumps can handle a wide range of fluids, including water, chemicals, oils, and slurries, making them suitable for diverse applications and environments.

- Low Maintenance: With fewer moving parts and simpler designs compared to other pump types, centrifugal pumps require minimal maintenance and downtime, enhancing reliability and productivity.

- Scalability: Centrifugal pumps are available in various sizes and configurations, allowing for scalability to meet specific flow rate and pressure requirements.

- Self-Priming Capability: Some centrifugal pumps are designed with self-priming capabilities, enabling them to evacuate air and create suction without external assistance, ideal for applications where priming may be challenging.

- Cost-Effectiveness: The relatively low initial investment coupled with long-term operational efficiency makes centrifugal pumps a cost-effective solution for fluid handling needs.

Innovations and Future Trends:

As technology advances and demands for greater efficiency and sustainability escalate, the centrifugal pump industry continues to innovate and evolve. Emerging trends include the integration of smart monitoring and control systems, predictive maintenance algorithms, and materials engineering for enhanced durability and performance. Additionally, there is a growing emphasis on energy-efficient designs, eco-friendly materials, and renewable energy sources to reduce the environmental footprint of pump operations.

Conclusion:

Centrifugal water pumps serve as indispensable assets in various industries, offering efficient, reliable, and versatile solutions for fluid management challenges. From agriculture to manufacturing, municipalities to mining, these pumps play a vital role in ensuring productivity, sustainability, and economic growth. By understanding the mechanics, applications, and advantages of centrifugal pumps, stakeholders can make informed decisions to optimize fluid handling systems and maximize performance in their respective domains. As we look towards the future, continued innovation and collaboration will drive further advancements in centrifugal pump technology, paving the way for a more efficient and sustainable fluid management landscape.

Comments