What Kinds of Stainless Steel Coupling Are There? Here are some of the key distinctions between these types. Stainless steel has a high chromium and iron content, which reacts with oxygen to form a passive layer, preventing rusting and allowing it to work in moist environments. Lower chromium alloys are less expensive, but their service life is short and maintenance costs are high. Carbon steel, on the other hand, is made of iron and contains 0.12 to 2% carbon. This steel is hard and resists deformation when subjected to impact loads.

What exactly is a Stainless Steel Coupling?

316 stainless steel is used to make stainless steel couplings. Because of their higher nickel and molybdenum content, these are more corrosion-resistant. Hygienic couplings are intended for use in biotechnology, chemistry, and pharmaceuticals. They must comply with strict hygiene standards and be compatible with the cleaning process. These couplings' inner surfaces must be free of crevices and dead spaces. It should also be smooth on the outside.

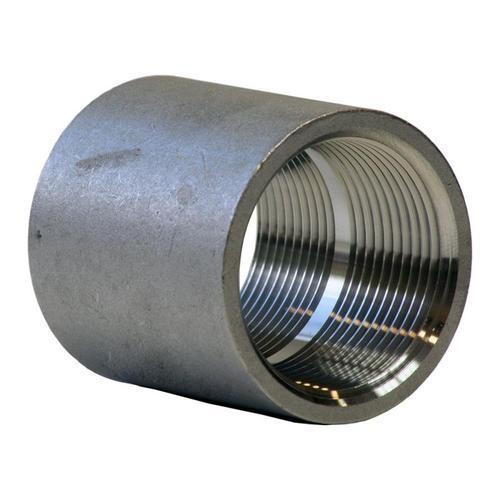

A cast pipe fitting is another type of coupling. The female National Pipe Taper (NPT) threads on this coupling are made of stainless steel. They are ideal for joining pipes of varying diameters. These couplings come in a variety of materials and are commonly used with water, gas, and oil. They are inexpensive and simple to set up. They are also lead-free. If you know how you can even install them

Stainless Steel Coupling Varieties

There are numerous types of stainless steel couplings. They can be threaded, rounded, or flat. In the dairy, food, and chemical industries, most stainless steel couplings have a D-shaped seal made of silicone, NBR, or EPDM. They can withstand pressures of up to 16 bars. While some are made of other materials, the vast majority are made of 304 stainless steel. Some examples of stainless steel couplings are provided below.

Stainless steel is a versatile material that can withstand corrosion without the use of additional coating. It has a wide range of applications, including indoor and outdoor plumbing. This material is also highly heat resistant and can be used in sanitary applications. Furthermore, stainless steel is more recyclable than ordinary steel and has a higher residual scrap value. As a result, it is an excellent choice for plumbing applications as well as a variety of other industrial settings.

Comments