Aluminum and vanadium are added to the titanium alloy used to create titanium grade 5 round bars. This grade of titanium alloy is the most popular because of the material's extremely excellent corrosion-resistant qualities. Titanium Gr 5 Round Bar products come in a wide range of sizes, forms, and varieties, and Navstar Steel is one of the industry's top producers and suppliers. The composition consists of 90% titanium, 6% aluminum, 4% vanadium, carbon, iron, and oxygen. The minimum tensile and yield strengths for these goods are 950 MPa and 880 MPa, respectively. ASTM B348 is the specification for this grade.

The melting point of the ASTM B348 Gr 5 Rod is an extremely high 1662 degrees Celsius. According to the EN, DIN, JIS, ASTM, BS, ASME, and AISI standards, the dimensions change. The bars' dimensions range from 5mm to 500mm in width, 0.1mm to 100mm in diameter, and 100mm to 3000mm in length, as well as bespoke lengths. The Grade 5 Titanium Flat Bar and others can have a variety of finishes, including black, brilliant, rough turned, and more. Other shapes include hexagonal and square rods and bars.

Different tolerance levels of the material are available, including H8 through H13 and K9 through K12. Due to its geometrical shape and strength, UNS R56400 titanium hex bars are employed in structural applications. The Titanium Grade 5 Square Bar can be used for applications where weight, shape, and strength are all important considerations. Heat exchangers, power plants, petrochemical plants, chemical processing businesses, offshore oil drilling applications, and more are among the applications. There are furthermore unique ends, such as the threaded end of the Titanium ASTM B348 Grade 5 Threaded Rod, which allows for connection to other threaded fittings and flanges.

Titanium Grade 5 Round Bar Types

- Titanium Alloy Grade 5 Rod

- Grade 5 Titanium Bar Material

- Gr 5 Titanium Flat Bar

- Titanium Grade 5 Hex Bar

- Ti Alloy 6al4v (Gr5) Bright Bar

- Gr 5 Titanium Alloy Rounds

- ASTM B348 Grade 5 Titanium Annealed Bar

- ASTM B348 Ti Grade 5 Flat Bar Hot Rolled

- Titanium Din 3.7165 Round Bar Cold Drawn

- UNS R56400 Titanium Flat Bar Cold Drawn

- Gr 5 Titanium Square Bar Hot Rolled

- Titanium Grade 5 ASTM B348 Round Bar Hot Rolled

Grade 5 Titanium Filler Rod Application

- Plate bases

- Aerospace

- Chemical transformation

- Medical devices

- Fasteners

What is the purpose of Titanium Grade 5?

Grade 5 Titanium (Ti-6Al-4V) is frequently used in demanding applications where a material that can simulate bone is required, such as for biomedical implants or for structural uses requiring high temperatures, like those found in the aerospace sector. Vanadium is a crucial alloying component for both Grade 9 and Grade 5 Titanium.

Is Grade 5 Titanium Pure?

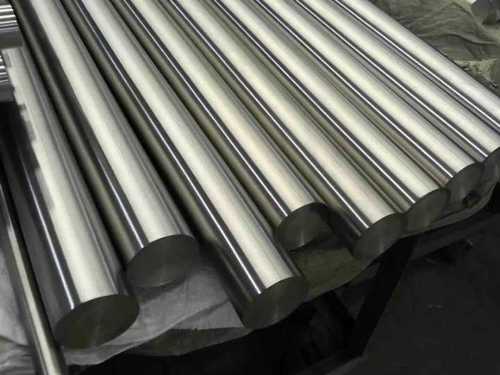

Image for Round Titanium Gr. 5 Bar

As an alloyed titanium, titanium Grade 5 is regarded as an alpha-beta alloy. Ti 6Al-4V is the popular name for Titanium Grade 5, an alloy of titanium with 6% aluminum and 4% vanadium. Titanium Engineers offers titanium Grade 5 machined parts, seamless titanium tubes, and titanium bars.

Which Titanium Alloy is Superior, Grade 2 or Grade 5?

Grade 2 titanium is "commercially pure" offers corrosion resistance and is lightweight, although it isn't quite as robust as alloys like Grade 5. Titanium alloyed with 6% aluminum and 4% vanadium is known as Grade 5, or Ti 6Al-4V. The resulting alloy improves resistance to heat and corrosion while also increasing strength.

Comments