Introduction

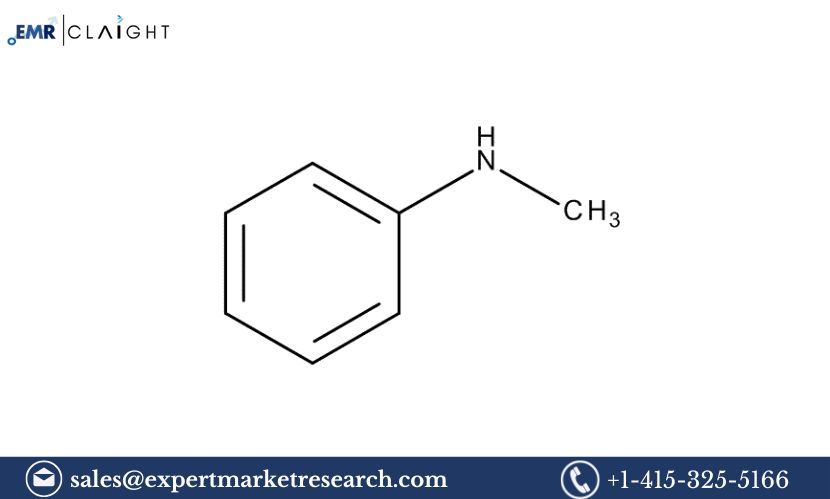

N-Methyl aniline, a key aromatic amine with the chemical formula C₇H₉N, is primarily used as an intermediate in the production of dyes, pharmaceuticals, and agrochemicals. Its unique properties, including solubility in organic solvents and reactivity, make it essential in various industrial applications. The growing demand for N-Methyl aniline in different sectors presents a lucrative opportunity for establishing a manufacturing plant. This N Methyl Aniline Manufacturing Plant Project Report outlines the crucial aspects of setting up such a facility, including market analysis, production processes, equipment requirements, financial projections, and potential challenges.

Market Analysis

Global Demand

The global demand for N-Methyl aniline is driven by several factors:

- Dye Manufacturing: N-Methyl aniline is a vital precursor in the synthesis of various dyes, especially azo dyes, which are widely used in textiles and printing.

- Pharmaceuticals: It plays a role in the synthesis of pharmaceutical compounds, including analgesics and anesthetics.

- Agrochemicals: The compound is used in the formulation of pesticides and herbicides, contributing to its increasing demand in the agriculture sector.

Regional Insights

- North America: The United States is a significant market for N-Methyl aniline, supported by its extensive chemical manufacturing base.

- Europe: Countries like Germany and the UK are major consumers, driven by strong industries in dyes, pharmaceuticals, and agriculture.

- Asia-Pacific: Rapid industrial growth in countries such as China and India presents substantial opportunities, as these nations expand their manufacturing capabilities and agricultural sectors.

Get a Free Sample Report with Table of Contents@

Project Description

Objectives

The primary objective of establishing an N-Methyl aniline manufacturing plant is to produce high-quality N-Methyl aniline that meets industry standards and caters to both domestic and international markets. The project aims for regulatory compliance while achieving profitability.

Location

Selecting the right location for the manufacturing facility is critical. Key considerations include:

- Proximity to raw material suppliers, particularly aniline and methylating agents.

- Accessibility to transportation networks for efficient distribution of products.

- Availability of skilled labor in the area.

- Compliance with local regulations and zoning requirements.

Production Process

The manufacturing process for N-Methyl aniline generally involves several key steps:

- Raw Material Procurement: The primary raw materials include aniline and methylating agents such as dimethyl sulfate or methyl iodide.

- Methylation Reaction: The methylation process involves reacting aniline with the methylating agent in the presence of a suitable solvent and catalyst under controlled conditions.

- Separation and Purification: After the reaction, the product mixture is separated, and N-Methyl aniline is purified using distillation or recrystallization to achieve the desired purity.

- Quality Control: Samples of the finished product undergo rigorous testing to ensure they meet safety and quality standards.

- Packaging: The purified N-Methyl aniline is packaged in suitable containers with proper labeling and safety precautions.

- Distribution: The packaged product is distributed to various industries, including textiles, pharmaceuticals, and agriculture.

Equipment and Technology

Essential equipment for an N-Methyl aniline manufacturing plant includes:

- Reactor Vessels: For conducting the methylation reaction.

- Distillation Columns: For separating and purifying the N-Methyl aniline from by-products.

- Storage Tanks: For safe storage of raw materials and finished products.

- Quality Control Equipment: For testing the quality and safety of the product throughout the manufacturing process.

Financial Projections

Startup Costs

Startup costs for an N-Methyl aniline manufacturing plant encompass several factors, including:

- Land Acquisition: The cost of purchasing land for the facility.

- Construction Costs: Expenses related to building the manufacturing plant and necessary facilities.

- Equipment Purchases: Investment in machinery and technology for production.

- Licensing and Permits: Costs associated with obtaining necessary regulatory approvals.

- Working Capital: Funds required for raw materials, labor, and operational expenses.

Revenue Projections

Revenue generation will depend on factors such as production capacity, market demand, and pricing strategies. A comprehensive market analysis is essential to accurately forecast potential sales volumes.

Profitability Analysis

The profitability of the plant will be influenced by several elements:

- Production Efficiency: Maximizing output while minimizing waste is crucial.

- Market Prices: Fluctuations in the price of raw materials and competition can impact profit margins.

- Operational Costs: Effective management of labor, energy, and material costs is essential for financial health.

Break-even Analysis

Conducting a break-even analysis is vital to determine when the plant will start generating profits. This analysis should consider fixed and variable costs alongside expected sales volumes.

Environmental Considerations

Establishing an N-Methyl aniline manufacturing plant requires attention to environmental responsibilities. Key considerations include:

- Waste Management: Implementing strategies for effective disposal and recycling of production waste.

- Compliance with Environmental Regulations: Adhering to local regulations regarding emissions and waste disposal.

- Safety Protocols: Ensuring proper safety measures are in place to protect workers and the environment from the hazards associated with chemical manufacturing.

Challenges and Risks

Market Fluctuations

The N-Methyl aniline market can experience volatility, with changes in demand affecting profitability. Manufacturers must stay informed about market trends and adapt strategies accordingly.

Regulatory Compliance

Navigating the complex regulatory landscape can be challenging. Continuous monitoring and compliance efforts are essential to avoid penalties and ensure product safety.

Supply Chain Disruptions

Disruptions in the supply chain for raw materials can impact production schedules. Building strong relationships with suppliers and maintaining adequate inventory levels can help mitigate these risks.

FAQs

1. What is N-Methyl aniline used for?

N-Methyl aniline is primarily used as an intermediate in the production of dyes, pharmaceuticals, and agrochemicals.

2. What are the main raw materials for producing N-Methyl aniline?

The primary raw materials include aniline and methylating agents, such as dimethyl sulfate or methyl iodide.

3. What is the production process for N-Methyl aniline?

The production process involves the methylation of aniline with methylating agents, followed by separation, purification, and packaging of the finished product.

4. What are the key challenges in establishing an N-Methyl aniline manufacturing plant?

Key challenges include market fluctuations, regulatory compliance, supply chain disruptions, and ensuring safety in handling chemicals.

5. How can I assess the profitability of an N-Methyl aniline manufacturing plant?

Profitability can be assessed through detailed financial projections, including startup costs, revenue forecasts, operational costs, and break-even analysis.

6. What environmental considerations should be taken into account?

Manufacturers should focus on effective waste management, compliance with environmental regulations, and implementing safety protocols to protect workers and the environment.

Related Reports

https://www.expertmarketresearch.com/reports/agricultural-surfactants-market/market-growth

https://www.expertmarketresearch.com/reports/database-management-system-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

Comments