A Simple Guide on Hastelloy C276 Chemical Composition

Hastelloy C276 is a nickel-molybdenum-chromium alloy with a trace amount of tungsten that has been reinforced by solid solution. Excellent corrosion resistance is displayed by alloy C-276 in a number of challenging environments and media. It is ductile, readily made, and weldable, like many other nickel alloys. Most industrial locations where there are hostile chemical conditions present and other alloys have failed employ this alloy. The alloy offers high resistance to sulfuric, hydrochloric, formic, acetic, and phosphoric acids. Hastelloy C276 Chemical Composition and Applications. The performance of alloy C-276 is excellent in situations with acid chlorides.

Industries and Applications

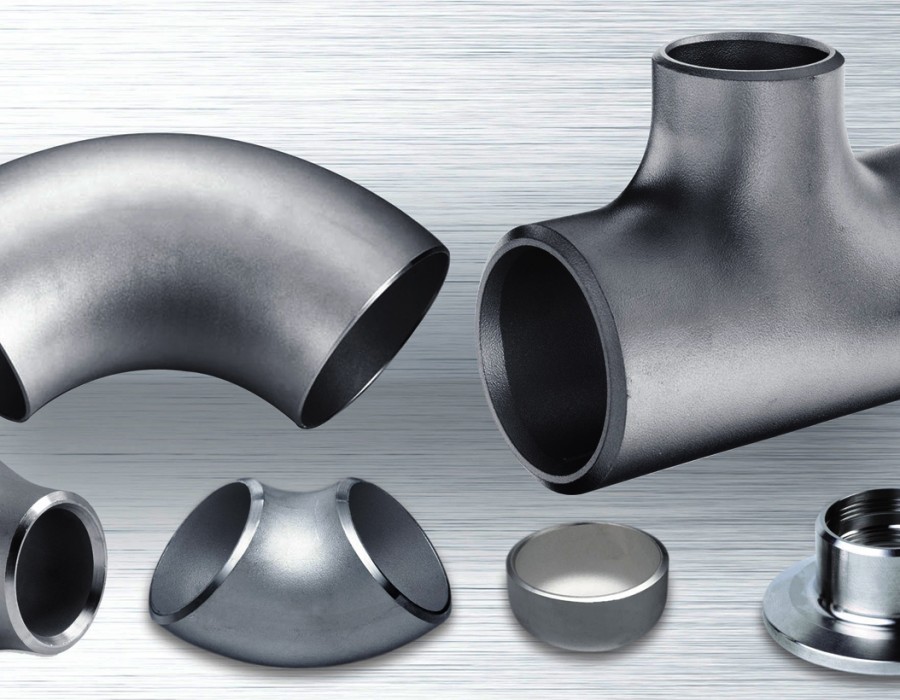

Hastelloy C276 is extensively used in a variety of industries, including waste water treatment, oil and gas production, pulp and paper manufacturing, pharmaceutical manufacturing, chemical and petrochemical processing, and power generating. Stack liners, ducts, dampers, scrubbers, stack gas reheaters, heat exchangers, reaction vessels, evaporators, transfer pipework, and several more extremely corrosive applications are examples of end use applications.

Resistance to Corrosion

One of the most widely used corrosion-resistant alloys on the market today is Hastelloy C276. It can be employed in a range of situations, from strongly reducing to moderately oxidising ones. Sulfuric acid, hydrochloric acid, formic acid, acetic acid, chlorides, solvents, wet chloride gas, and hypochlorite and chlorine solutions are among the substances to which alloy C-276 has extraordinary resistance. When exposed to phosphoric acid at any temperature below boiling and in concentrations lower than 65%, Hastelloy C276 exhibits outstanding resistance. Low chromium content is the limiting element when dealing with strong oxidising conditions, hence hot concentrated nitric acid settings are undesirable.

Hastelloy C276 has exceptional resistance to oxidising environments, stress corrosion cracking, and pitting. Additionally, alloy C-276 demonstrates resistance to vigorous assault from seawater corrosion in crevice circumstances, which can cause corrosion in other frequently used materials.

Fabrication and Heat Treatment

Numerous cold and hot working techniques can be used to manufacture hastelloy C276. Alloy C-276 work hardens quickly, like other nickel alloys, although it can be cold formed utilising forceful techniques including deep drawing, press forming, and punching. Heavy parts should be heated to a minimum temperature of 2000°F prior to hot forming, with the temperature range for hot forming being between 1600°F and 2250°F (870°C and 1230°C). It is recommended to anneal the material after working it at a temperature between 2050°F and 2150°F, then quickly quench it in a protective environment. atmosphere or agitated reducing quench bath. To obtain a reducing quench bath, add 2% (by volume) of either ethyl or propyl alcohol to water.

Comments