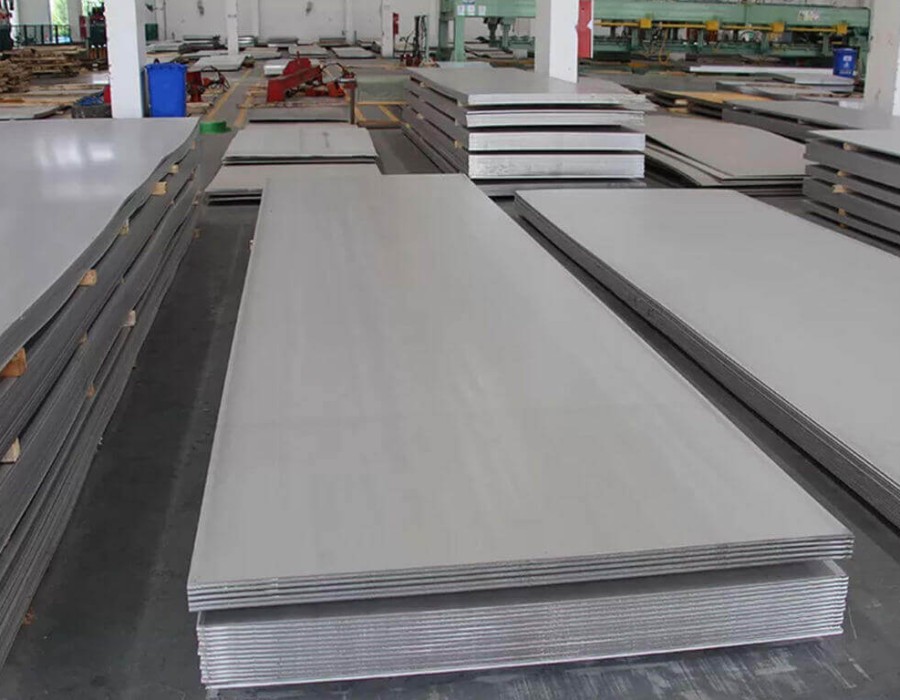

What are Stainless Steel 347 Sheets?

Stainless steel is a versatile material that has made its way into various industries such as construction, automotive, and aerospace, just to name a few. Stainless steel 347 is one such variant that is becoming increasingly popular due to its superior properties. Proper maintenance of Stainless Steel 347 Sheets is essential to ensure their longevity. It is recommended to clean them regularly using a mild detergent and a soft cloth. Avoid using abrasive cleaners, which can damage the surface of the sheets. Additionally, periodic inspection and maintenance of equipment made from stainless steel 347 are necessary to identify potential issues before they become major problems.

Features of Stainless Steel 347 Sheets

Stainless steel 347 is an austenitic steel, meaning it has a high resistance to corrosion. It contains elements such as chromium and nickel, which provide it with additional protection against oxidization. Additionally, stainless steel 347 sheets are non-magnetic, making them suitable for use in certain applications. The sheets have excellent welding and forming properties, making them versatile across different industries.

One of the main benefits of using stainless steel 347 sheets is their high-temperature resistance. They are ideal for use in applications that involve high temperatures, such as chemical processing and oil refining. Another benefit is their ability to withstand high stress, making them perfect for heavy-duty machinery and equipment.

Applications of Stainless Steel 347 Sheets

The superior properties of Stainless Steel 321 Sheets make them suitable for a variety of applications. They are commonly used in the manufacturing of petrochemical equipment, heat exchangers, chemical processing equipment, and aerospace components. They are also used in the construction of piping systems, boiler casings, and exhaust systems in the automotive industry.

Stainless steel 347 sheets can be easily fabricated due to their excellent welding and forming properties. They can be cut, welded, and shaped into desired shapes and sizes. However, care should be taken during welding to avoid oxidation. It is recommended to use a shielding gas such as argon to protect the weld zone from atmospheric contamination.

Comments