An establishment

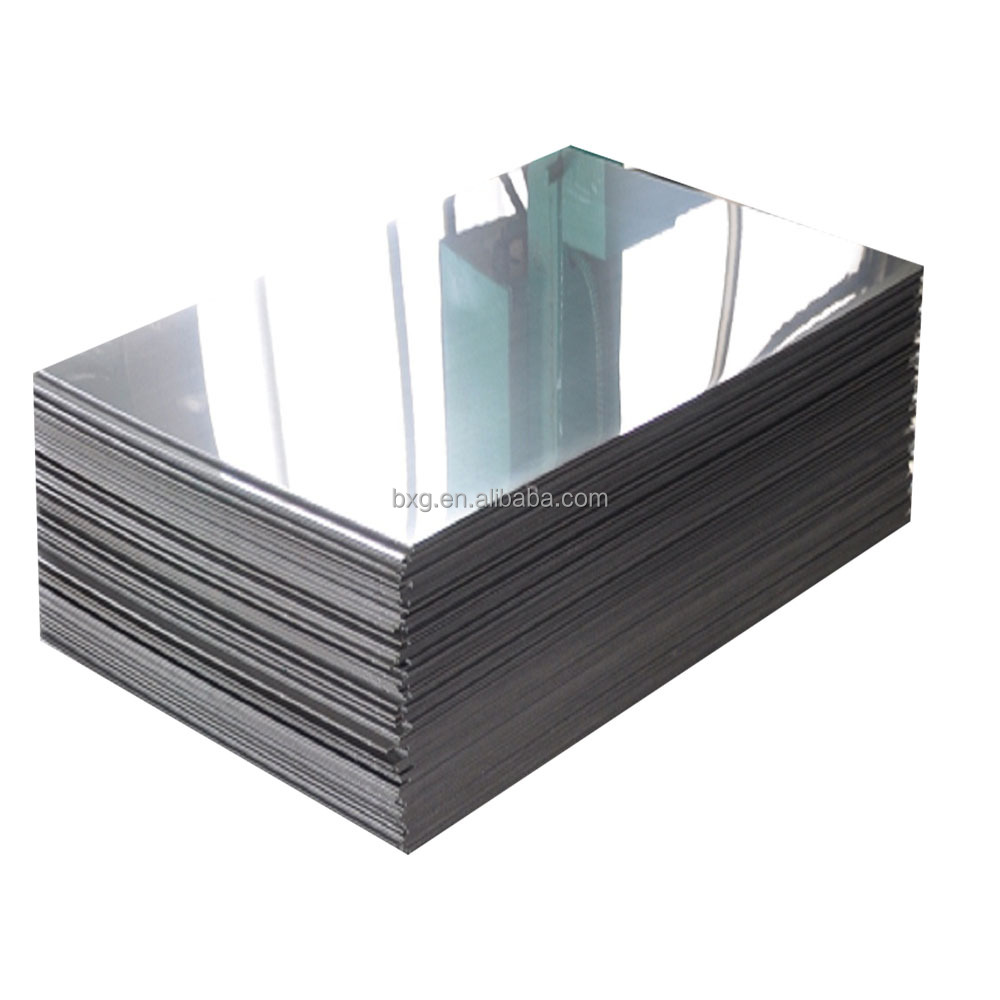

Stainless steel also referred to as inox steel, has a minimum bulk content of 10.5% chromium. Because it does not easily rust, corrode, or stain when in contact with water, it is widely employed in a variety of industries. Stainless steel is also available in a variety of grades and surface treatments, each with its unique characteristics for withstanding particular environments and uses.

What it does

So how do rust, corrosion, or discoloration affect stainless steel? The chromium in Stainless Steel Shim creates a shield of chromium oxide that is passive. By obstructing oxygen flow to the steel's surface and into the metal's interior structure, it so avoids surface corrosion. Because of this, stainless steel shim material is suitable for a wide range of applications in numerous sectors.

Uses of steel shim

- Machinery alignments and fine adjustments

- Setup of tools and dies

- Replacement parts for machines

- maintenance of machines

- mounting of machineries such as pumps and motors

- work in the prototype.

selecting the proper shim

When selecting the best shim for your application, it is important to consider the material composition as well as the mechanical and physical parameters. To guarantee that each shim is appropriate for its purpose, we offer custom alternatives for our shims in a variety of thicknesses and materials. At Stephens Gaskets, we use a variety of materials, such as copper, brass, plastic, aluminum, and stainless steel. Additionally, we offer pre-cut stock shim washers in the majority of our frequently used shim materials, which satisfy the majority of design specifications for most applications.

Comments