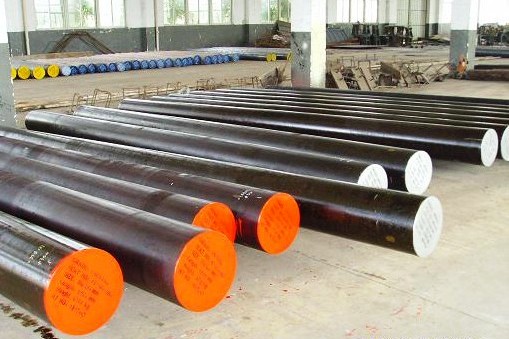

Medium carbon steel with good strength, hardness, and wear resistance is AISI 1045 carbon steel round bar. Due to its adaptability and ease of machining, it is a popular choice for producing a variety of mechanical parts, including shafts, axles, gears, and more. Its prominence in industrial applications is a result of this. The balance of strength and ductility in AISI 1045 is one of its key benefits. It offers good machinability, simple weldability, and enforceability due to its mild carbon concentration. In comparison to other high-carbon steel grades like AISI 1050 and AISI 1095, it is also a more affordable choice.

Due to its great strength and hardness, AISI 1045 carbon steel round bar is the perfect material for heavy-duty machinery and equipment. It is an appropriate material for components susceptible to severe stress and friction due to its good wear resistance. Moreover, it is frequently used for fasteners, agricultural machinery, and hand tools. Visit one of our locations or get in touch with us for additional information if you want to learn more about the AISI 1045 Standard pdf.

Corrosion Resistance of AISI 1045 Carbon Steel Round Bar

Because it contains very little chromium, AISI 1045 carbon steel round bar has a low level of corrosion resistance. In situations with moisture, oxygen, and other corrosive substances, it is prone to rust and corrosion. A protective layer or plating can be applied to AISI 1045 carbon steel round bars to increase their corrosion resistance. Zinc, nickel, and chrome are often used coating compounds that act as a shield between steel and corrosive substances.

Using a corrosion inhibitor is another technique to improve the corrosion resistance of AISI 1045. Chemicals known as corrosion inhibitors are applied topically or added to the environment in order to stop or slow down corrosion on metal surfaces. Phosphates, nitrates, and chromates are a few examples of corrosion inhibitors for carbon steel. It is crucial to remember that the effectiveness of corrosion inhibitors and coatings might vary depending on the precise corrosive environment and the length of exposure. Decide on the best protection strategy after thoroughly assessing the application's requirements for corrosion resistance.

Heat Treatment and Machinability of AISI 1045 Carbon Steel Round Bar

Heat treatment can be used to increase the strength, hardness, and other mechanical qualities of the AISI 1045 carbon steel round bar. To attain the necessary qualities, it can be put through procedures including annealing, normalizing, quenching, and tempering. Steel is heated to a certain temperature and then gently cooled during an annealing process, which can enhance its machinability and lessen internal tensions. In order to increase the steel's strength and toughness, normalizing requires heating the metal to a higher temperature than annealing and then allowing it to cool in the air. Whereas tempering entails heating the quenched steel to a lower temperature to lessen its brittleness, quenching includes rapidly cooling the steel in water or oil to harden it.

Compared to high carbon steel grades like AISI 1050 and AISI 1095, AISI 1045 carbon steel round bar is well known for its good machinability. Because of its modest carbon concentration and adaptable qualities, it can be used for a variety of machining operations, including drilling, turning, and milling. AISI 1045 carbon steel round bar can be annealed, normalized, or quenched and tempered to increase its machinability. These heat-treatment procedures can also enhance the steel's mechanical characteristics, such as its strength and hardness.

Comments