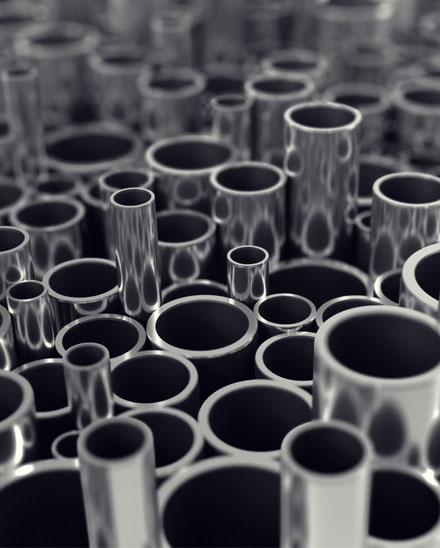

What are the Stainless Steel 304 Tubes?

When determining which grade of stainless steel 304 tubes to use, many criteria are taken into account. The ability to resist corrosion in a specific application or environment is a critical property of stainless steel. Strength and fabrication characteristics are also taken into account. Stainless steel is frequently distinguished by kind and grade in addition to such classifications. Because it is exceptionally chemical and corrosion-resistant, type stainless steel 304 is a popular choice for tube and pipe applications.

However, due to a material content limit of 0.08 percent carbon, type 304 stainless steel is not suitable for applications with temperatures between 800 and 1640 degrees F because it is prone to carbide precipitation. This difficulty is solved by Stainless Steel 304 Tubes, which have a lower carbon content and may be used for welding and high-temperature applications. Additives (such as nickel or molybdenum) are frequently used in other varieties of stainless steel to strengthen properties that are helpful in specific applications.

Applications of Stainless Steel 304 Tubes

Corrosion-Resistance

The general type of steel is appropriate for applications requiring overall corrosion resistance. Steels that are ferritic or martensitic (those with the highest chromium content) are made to be heat-treated or annealed. Austenitic stainless steels (those containing a high amount of chromium and nickel) provide even higher resilience and can be utilized under the same conditions as ferritic and martensitic varieties.

Sanitary Tubing

Hygiene is a top consideration in situations where stainless steel 304 tubes or pipes come into touch with food or other sensitive products. In these applications, stainless steel sanitary tubes are employed because they are corrosion resistant, do not tarnish, and are simple to clean. For certain applications, a variety of tolerances can be attained. ASTM A270 is the most common grade for these uses.

Aircraft Hydraulic-Line Tubing

Hydraulic-line tubing is a smaller type of aviation tubing that is commonly used in aerospace applications like fuel injection lines and hydraulic systems. Because of the steel's excellent strength, durability, and ductility, it's also made of grade 304 or 304L stainless steel.

Comments