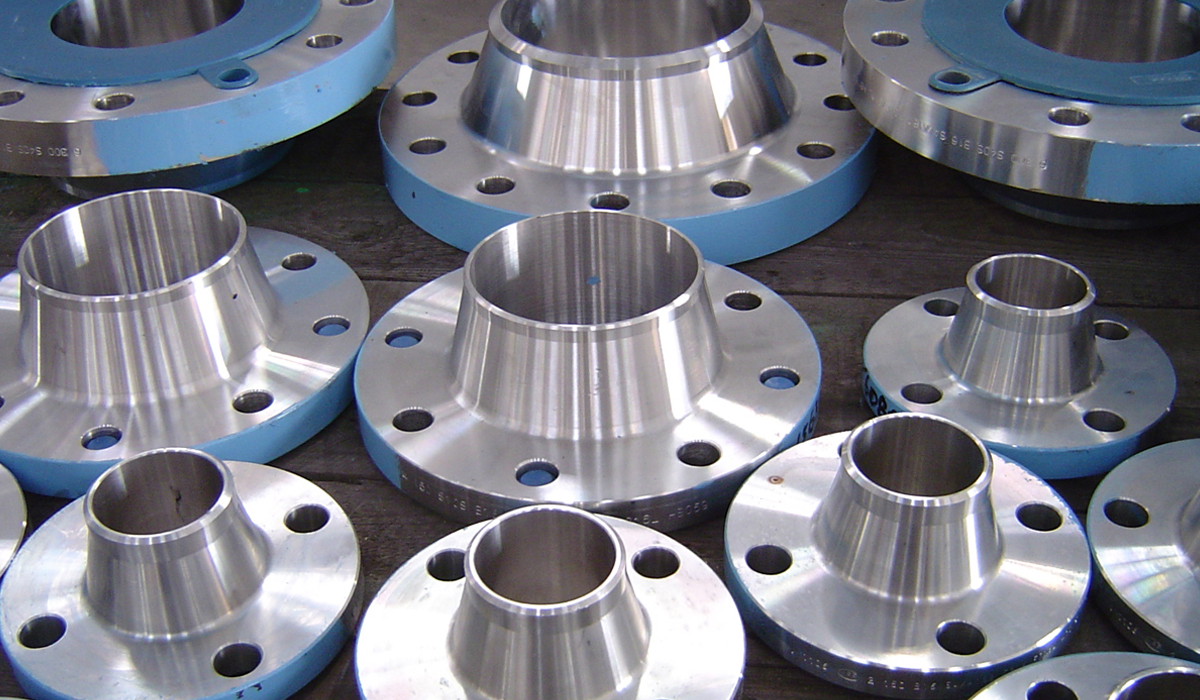

Industrial and engineering applications often demand the use of flanges that can withstand harsh and corrosive environments. This is where SS 316H flanges come in, austenitic stainless steel that provides superior strength and resistance to high temperatures and corrosives. Despite being a highly sought-alloy for various industries, many are still unaware of its properties and benefits. In this article, we will cover the key points you need to know about this product, including its applications, properties, and benefits.

Applications of SS 316H Flanges

Machinery, oil, and gas

Chemical processing industry

Pharmaceutical engineering

Marine and shipbuilding

Heat exchanger and boiler construction

Pulp and paper industry

These sectors rely on SS 316H flanges due to their ability to withstand high temperatures, pressure, and aggressive chemicals. Besides, their non-magnetic and ductile nature makes them an excellent choice for the manufacture of pipelines and pressure vessels.

Properties of SS 316H Flanges

One of the key properties of SS 316H flanges is their ability to withstand temperatures of up to 1700°F (925°C), which makes it a preferred choice in High-temperature applications. Additionally, it has excellent welding and forming abilities despite its high carbon content. This alloy is non-magnetic, has a low coefficient of thermal expansion, and is great at working in cryogenic temperatures. Stainless Steel 316H flanges have excellent resistance to pitting and crevice corrosion induced by chloride solutions, which is why it is used extensively in marine engineering.

Benefits of SS 316H Flanges

- Great resistance to corrosion and erosion

- Excellent strength at high-temperature conditions

- High ductility and exceptional formability

- Superb weldability and machinability

- Perfect for use in both cryogenic and high-temperature applications

- Non-magnetic and resists carbide precipitation, even at high temperatures

These features make SS 316H flanges an excellent metal choice for industrial applications that demand exceptional strength, corrosion resistance, and durability.

Maintenance of Stainless Steel 316H Flanges

Maintenance of SS 316H flanges can be carried out easily with regular cleaning and maintenance activities done as per the manufacturer's standard instructions. Proper storage and handling of flanges during transportation, installation, and usage are essential to ensure their durability and longevity.

Conclusion:

In conclusion, SS 316H flanges are reliable and versatile alloys with excellent properties and benefits, making them ideal for a wide range of industrial and engineering applications. The alloy's superior characteristics, such as corrosion resistance, versatility, and strength, make it a metal of choice for various sectors. Whether you're manufacturing heat exchangers or chemically resistant pipes, these products are your best bet. Regular maintenance as per the manufacturer's instructions ensures that you maintain their life for longer. So, when next you are looking for a metal for that next project, consider SS 316H Flanges and enjoy the benefits.

Comments