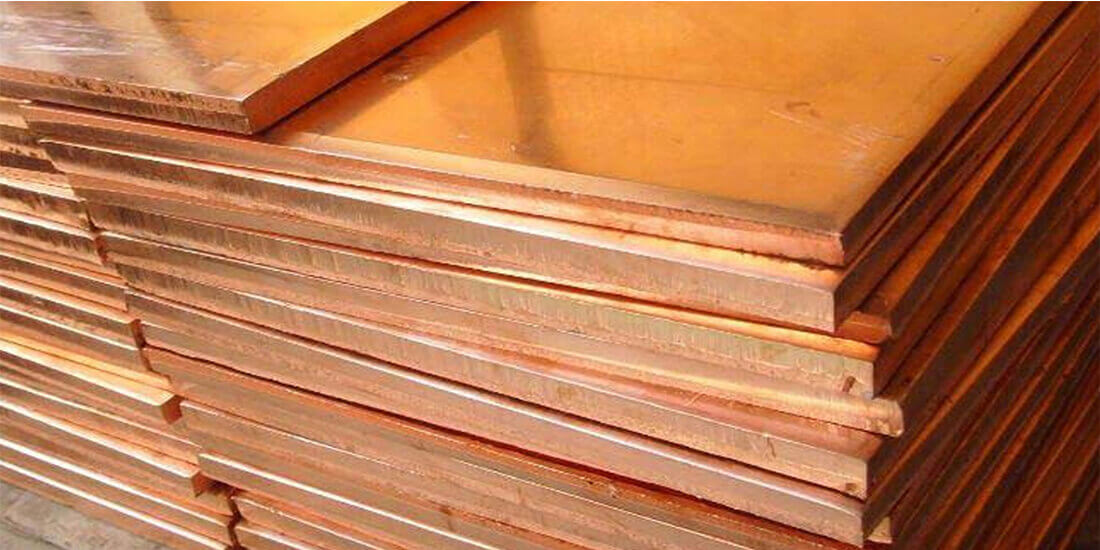

What are the Copper Nickel 70/30 Sheets?

Due to their excellent resistance to seawater infiltration, effectiveness in reducing macrofouling levels, and outstanding texturing capacity, copper nickel 70/30 sheets are one of the most popular pairings for a variety of applications. They have additionally been used for other reasons due to their excellent durability, antibacterial qualities, and attractiveness. The item's overall design is guided by national and international standards for raw material quality.

Copper Nickel 70/30 Sheets, with atomic weights 63.54 and 68.71 and atomic weights 29 and 28, are located close to one another in this sporadic arrangement of elements. The two components are completely miscible in both the fluid and strong states and have a strong relationship. Over the whole focus run in a face-focused cubic grid, copper nickel 70/30 sheets. With nuclear fixation, the grid separating the face-focus cubic strong arrangement changes between the qualities for copper and those for a nickel.

Copper (the base metal with the largest individual component) and nickel, with or without additional components, are combined to form copper nickel 70/30 sheets, with a maximum of 1% zinc content. When several components are accessible, nickel has the largest individual substance, second only to copper, when compared to every other component. Similar to other copper amalgams, it's critical to distinguish between cast composites, from which castings are made using various casting techniques, and fashioned compounds, which are manufactured into semi-completed products.

Advantages of Copper Nickel 70/30 Sheets

Copper Nickel 70/30 Sheets have become the ideal product with a variety of acceptable focus points to offer due to the feasibility of their manufacturing. Because of its great quality, amalgam offers brilliant qualities including high elasticity, reusability, and amazing formability. Additionally, these products offer greater protection from high temperatures, high protection from heavy loads, and outstanding resistance to mechanical stresses.

Comments