Stainless Steel is an extremely versatile metal alloy that can be shaped and formed into numerous components. One of these components that are widely used is the Stainless Steel Coil. Just like its alloy, these coils are resistant to corrosion and are rust and abrasion resistant. As we already know, this property is due to the chromium oxide layer formed by the reaction that takes place between the chromium in stainless steel and the oxygen in the atmosphere. The chromium oxide layer that protects the stainless steel coils from rust, abrasion, and corrosion is a self-repairing layer and does not need any additional maintenance. Most of the properties that are seen in Stainless steel such as heat resistance, corrosion resistance, machining, versatile processing, etc. are inherited by stainless steel coils.

Let's take a deeper look at some of the advantages or benefits of Stainless Steel Coils:

1. Machining:

Commonly used Stainless steel coils include grade 304 and grade 321. Among the two, grade 304 is not as tough and sturdy as grade 321. But both of these grades can be machined smoothly. However, some might require annealing post the welding or cutting process. Annealing ensures the retainment of anti-corrosive properties. Welding fluids should be used appropriately to avoid tarnishing the integrity of the alloy. Stainless steel elements regain their strength and durability post the welding or machining procedure.

2. Welding Stainless Steel Coils:

Stainless steel coils can be welded using all traditional methods. It is advised to carry out the welding process using filler materials. Grade 321 has an upper hand in this process as it eliminates and prevents the formation of carbon precipitate and carbide during the welding process. This additional enhancement in grade 321 stainless steel comes due to the addition of titanium in its alloying composition. Annealing the material post-weld will ensure maximum malleability and ductility.

3. Hot and cold working methods:

To forge and form grade 321 Stainless steel it is advised to work with temperatures above 1700 degrees Fahrenheit. The stainless steel coils should be completely annealed or water-quenched in order to retain ductility and corrosion resistance.

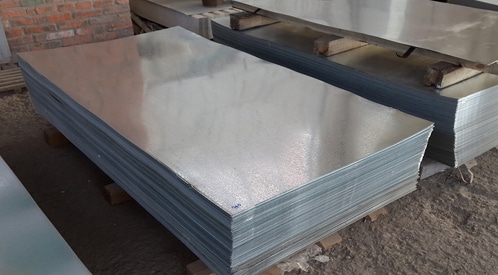

Coils that are processed through cold working have a smooth and shiny finish. Whereas coils that are hot-rolled or hot worked to have a rustic finish. Cold rolled coils are stronger and have better structural integrity and great toughness. Cold finished coils are used for external applications such as beautifying structures.

4. Corrosion Resistance:

Stainless Steel coils are resistant to most types of corrosion. They are protected by the chromium oxide layer that forms on its surface. However, between grade 321 and grade 304 stainless steel, grade 321 stainless steel has better corrosion resistivity. When grade 304 stainless steel is not stabilized it is prone to intergranular corrosion. However, the overall general corrosion resistivity offered by stainless steel coils is brilliant.

Comments