Ship launching and maintenance require reliable technology that ensures both safety and efficiency. A marine rubber airbag has become an indispensable tool in this process. These airbags are widely used for launching ships, lifting heavy structures, and assisting in dry-docking operations. Their flexibility, durability, and cost-effectiveness have made them a preferred choice for many shipyards and port operators.

The growing reliance on the marine airbag system highlights its importance in modern maritime industries. Unlike traditional methods, airbags offer greater adaptability and reduce the need for large fixed infrastructure. This makes them an efficient solution for shipbuilding, repairs, and heavy-duty lifting operations.

How marine airbags work

A marine rubber airbag is typically made of multiple layers of synthetic rubber and high-strength fabric. When inflated, it creates a cylindrical cushion that can bear heavy loads. These airbags are placed beneath vessels or structures, allowing smooth and controlled movement during launching or lifting.

The working principle of a marine airbag is simple yet highly effective. Its ability to distribute pressure evenly minimizes structural stress, ensuring safe handling of large vessels and offshore equipment. This makes airbags particularly useful in operations where precision and safety are critical.

Applications in the shipping industry

One of the most common uses of a marine rubber airbag is in ship launching. Airbags allow vessels of various sizes to be moved into the water without the need for permanent launching ramps. This method is not only cost-effective but also flexible, as it can be used in different locations.

A marine airbag also plays an important role in vessel maintenance. It helps lift ships for repairs, inspections, and repainting. Shipyards benefit from the reduced time and resources required compared to traditional dry-docking methods.

Benefits of marine airbags

The advantages of a marine rubber airbag go beyond cost savings. These airbags are portable and easy to install, allowing shipyards to carry out operations with minimal setup time. Their reusability further enhances their value, as a single set of airbags can be used multiple times across projects.

Another key benefit of a marine airbag system is its adaptability. Whether dealing with small fishing boats or large cargo vessels, airbags can be customized to meet varying load requirements. Their strong construction ensures safety and reliability under demanding conditions.

Safety and durability

Safety is paramount in ship launching and maintenance. A marine rubber airbag is designed to withstand high pressure and extreme conditions. Its multi-layered structure ensures that it can handle repeated use without compromising performance.

Regular inspections and proper handling further extend the lifespan of a marine airbag. With correct maintenance, these airbags can serve reliably for years, making them a dependable solution for shipyards worldwide.

Economic and environmental impact

Choosing a marine rubber airbag helps reduce the need for costly infrastructure such as dry docks or slipways. This results in significant cost savings for shipyards and operators. Additionally, the reduced construction footprint lowers environmental impact, making airbags a more sustainable option.

The reusability of a marine airbag also contributes to its eco-friendly profile. By minimizing waste and resource consumption, it supports greener practices within the maritime industry.

Final Thoughts

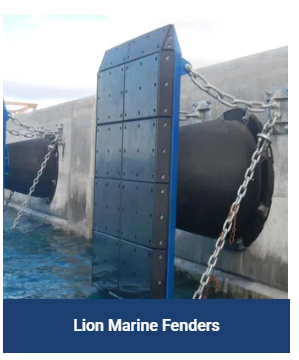

The versatility and reliability of marine airbags make them a vital part of modern shipbuilding and maintenance. Whether for launching, lifting, or repairs, both the marine rubber airbag and marine airbag solutions offer safety, cost savings, and efficiency. Trusted providers like Lion Rubber ensure high-quality products that meet the demanding needs of global maritime operations.

Comments