In the competitive production sector of today, the quality of the product is what can either make or destroy a brand name. Whether you are manufacturing packaging materials, fabrics, plastics, metals, or auto parts, it is important to confirm that your products have the necessary strength and endurance. One of the best methods of confirming this is by utilizing a tensile strength machine that determines the amount of force that must be applied to a material in order to cause it to fail.

Tensile testing is an essential component of quality control since it offers significant information regarding the mechanical properties of a material, which may consist of strength, elongation, and elasticity. In this article, we shall discuss the best reasons why a tensile testing machine should be applied for quality control, its uses in industries, and why it would be a wise investment for manufacturers to make.

Understanding Tensile Strength Testing

Tensile strength testing determines how much pulling force a material can withstand before it fractures. This test is essential for predicting how a product will perform under stress during real-life applications. For instance, in packaging, the tensile test ensures that plastic films and laminates do not tear during transportation. In the textile industry, it verifies that fabrics are strong enough to withstand daily wear and washing.

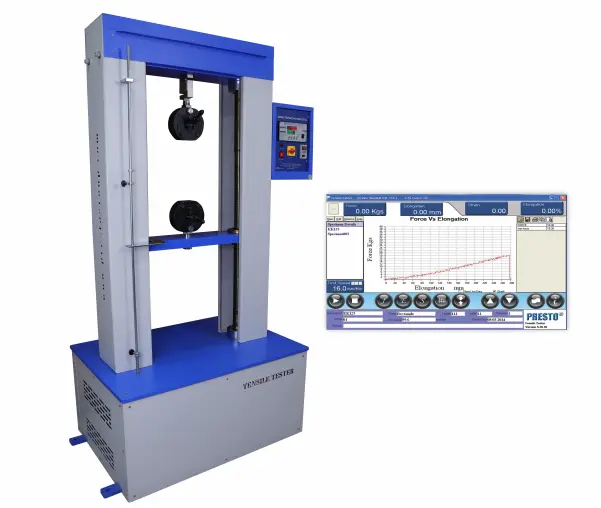

A tensile strength machine applies a controlled pulling force to a specimen and records data such as maximum load, elongation percentage, and break point. This quantitative data helps manufacturers maintain consistent product quality and comply with national and international testing standards like ASTM, ISO, and DIN.

Key Benefits of Using a Tensile Strength Machine

Accurate and Reliable Results

Manual testing methods can be inconsistent, leading to unreliable results and quality variations. Tensile testing machines provide precise measurements by applying a uniform force and recording data digitally. This accuracy ensures that manufacturers can make informed decisions about material selection and product design.

Improved Quality Control

Tensile testing allows manufacturers to identify weak points in raw materials and finished products before they reach the market. Detecting these issues early prevents product recalls, reduces customer complaints, and helps maintain brand reputation.

Compliance with Standards

Many industries must adhere to strict global quality standards to sell their products domestically and internationally. Tensile strength testing is a requirement for packaging, automotive, and construction materials. Using a testing machine helps manufacturers demonstrate compliance with these standards during audits and certification processes.

Cost Savings in the Long Run

While the initial investment in a tensile testing machine might seem high, it pays off by reducing material wastage, preventing defective product batches, and improving production efficiency. Accurate data also helps optimize raw material usage, lowering manufacturing costs over time.

Versatile Testing Capabilities

Modern machines can test a wide variety of materials, including plastics, metals, rubbers, textiles, composites, and wires. They can perform multiple test types such as tensile, compression, and flexural testing, making them a versatile addition to any quality control lab.

Data Analysis and Traceability

Advanced models come with software integration that allows users to store, analyze, and generate reports from test data. This feature is valuable for tracking trends, improving R&D efforts, and providing documented evidence during quality inspections or audits.

Applications Across Industries

A tensile strength machine in Bangladesh is used across numerous sectors, including packaging, textiles, automotive, aerospace, pharmaceuticals, and construction. For instance, packaging manufacturers rely on tensile testing to confirm the strength of plastic films and cartons, ensuring they do not fail during shipping. Textile companies test fabrics for tear resistance, while automotive manufacturers evaluate the strength of seat belts, rubber components, and metal fasteners.

Why Investing in Tensile Testing Makes Sense

As industries in Bangladesh continue to grow, so does the need for high-quality, globally competitive products. Investing in a tensile strength machine is not just about meeting compliance requirements; it is about ensuring long-term business success. Reliable tensile testing helps manufacturers build customer trust, improve production efficiency, and gain a competitive advantage in the marketplace.

About Presto Instruments

Presto Instruments is one of the leading manufacturers of precision testing equipment, including advanced tensile strength machines designed to deliver accurate and repeatable results. Their machines are built with robust construction, user-friendly controls, and compliance with international standards like ASTM and ISO. Presto also provides calibration services, training, and excellent after-sales support, making them a preferred choice for manufacturers who are serious about quality control and material testing.

Conclusion

Quality control is a vital aspect of any manufacturing process, and tensile testing plays a key role in ensuring products meet strength and durability requirements. By using a tensile strength machine, manufacturers can eliminate guesswork, enhance consistency, and comply with industry standards. The result is improved product reliability, reduced costs, and increased customer satisfaction. For companies looking to upgrade their testing capabilities, partnering with a trusted provider like Presto Instruments can ensure access to reliable equipment, expert guidance, and long-term support.

Comments