Introduction

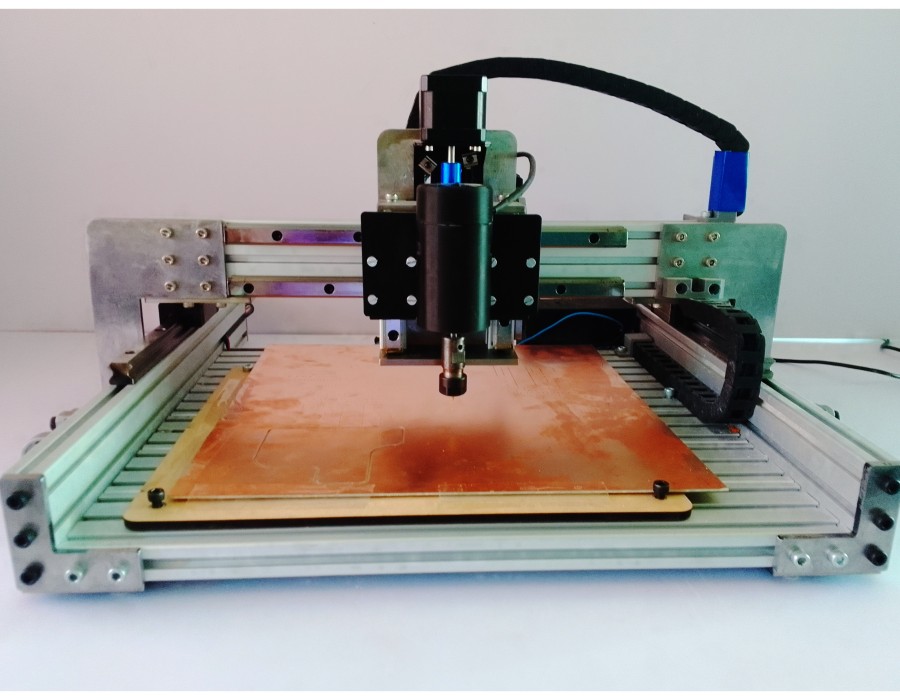

Norway's medical device manufacturing sector is experiencing a significant transformation, driven by the increasing demand for intricate and high-precision components. At the forefront of this evolution is the burgeoning adoption of micro-precision Norway CNC Drilling Machine Market. This article delves into the factors fueling this trend, the key technologies involved, the benefits it offers, the challenges faced, and the future outlook for this dynamic segment of the Norwegian manufacturing landscape.

Norway has established itself as a hub for high-quality manufacturing, and its medical device industry is no exception. Known for its stringent quality standards and focus on innovation, the sector is increasingly relying on advanced machining techniques to produce sophisticated medical devices. Among these techniques, micro-precision CNC drilling is emerging as a critical process, enabling the creation of intricate features and microscopic holes essential for the functionality and safety of modern medical instruments and implants.

The Growing Demand for Micro-Precision in Medical Devices

The medical device industry is characterized by constant innovation, leading to increasingly complex designs and miniaturization of components. This trend is particularly evident in:

- Minimally Invasive Surgery (MIS): MIS techniques require smaller and more intricate surgical instruments with precise functionalities, often involving micro-channels and minute apertures.

- Implantable Devices: From pacemakers and neurostimulators to cochlear implants and drug delivery systems, these devices demand extreme precision in their internal structures, often requiring micro-drilled holes for wiring, fluid flow, or sensor integration.

- Diagnostic Tools: Advanced diagnostic equipment, such as microfluidic devices and lab-on-a-chip systems, rely heavily on the creation of micro-channels and features through ultra-precise drilling.

- Orthopedic Implants: Even larger implants like screws, plates, and joint replacements often require precisely drilled micro-holes for secure fixation, osseointegration enhancement, or drug elution.

This escalating demand for miniaturization and complexity in medical devices is the primary driver behind the increased adoption of micro-precision CNC drilling in Norway. Traditional machining methods often fall short when it comes to achieving the required tolerances and surface finishes at such a microscopic scale.

Key Technologies Enabling Micro-Precision CNC Drilling

Several advanced technologies underpin the capabilities of micro-precision CNC drilling machines used in Norway's medical device manufacturing:

- High-Speed Spindles: Achieving the necessary cutting speeds for micro-tools (often with diameters in the micrometer range) requires ultra-high-speed spindles, capable of rotating at tens or even hundreds of thousands of revolutions per minute (RPM). This ensures efficient material removal and minimizes tool deflection.

- Advanced Motion Control Systems: Precise and smooth movements of the machine axes are crucial for micro-drilling. Linear motors, high-resolution encoders, and sophisticated control algorithms ensure sub-micron positioning accuracy and repeatability.

- Micro-Drills and Tooling: The development of extremely small and robust drill bits, often made from materials like solid carbide or polycrystalline diamond (PCD), is fundamental. Specialized coatings are also employed to enhance tool life and performance.

- Precision Work holding: Secure and accurate clamping of miniature work pieces is essential. Vacuum chucks, micro-vises, and custom-designed fixtures are commonly used to prevent vibration and ensure drilling accuracy.

- Real-Time Monitoring and Feedback Systems: In-process monitoring using sensors and cameras allows for real-time adjustments to drilling parameters, ensuring quality and preventing tool breakage. Feedback loops integrated with the CNC controller are vital for maintaining accuracy.

- Temperature Control: Maintaining a stable temperature during the micro-drilling process is critical due to the small scale involved. Even minor temperature fluctuations can affect the dimensions and surface finish of the drilled holes.

- Clean room Environments: Medical device manufacturing often requires clean room environments to prevent contamination. Micro-precision CNC drilling operations are frequently performed within these controlled spaces.

Benefits of Micro-Precision CNC Drilling for Norway's Medical Device Sector

The adoption of micro-precision CNC drilling offers numerous advantages for medical device manufacturers in Norway:

- Enhanced Precision and Accuracy: These machines can achieve tolerances down to the micrometer level, crucial for the intricate features required in many medical devices.

- Miniaturization Capabilities: Micro-drilling enables the creation of extremely small holes and features, facilitating the production of smaller and more complex medical components.

- Improved Surface Finish: The high speeds and precise control result in superior surface finishes, which are critical for the biocompatibility and functionality of medical devices.

- Material Versatility: Advanced micro-drilling machines can work with a wide range of materials commonly used in medical devices, including stainless steel, titanium, polymers, and ceramics.

- Increased Efficiency and Productivity: While the initial investment might be higher, CNC automation allows for consistent and repeatable production, leading to increased throughput and reduced cycle times.

- Reduced Material Waste: The precision of CNC drilling minimizes errors and scrap, leading to more efficient material utilization.

- Complex Geometries: Micro-precision CNC drilling enables the creation of complex hole patterns and geometries that are difficult or impossible to achieve with traditional methods.

- Enhanced Device Functionality: The ability to create intricate micro-channels and features directly translates to improved functionality and performance of medical devices.

Challenges in Implementing Micro-Precision CNC Drilling

Despite the numerous benefits, the implementation of micro-precision CNC drilling in Norway's medical device manufacturing also presents certain challenges:

- High Initial Investment: Micro-precision CNC machines and associated tooling can be significantly more expensive than conventional equipment.

- Skilled Workforce Requirement: Operating and maintaining these advanced machines requires highly skilled technicians and engineers with expertise in micro-machining.

- Tooling Costs and Management: Micro-drills are delicate and can be expensive. Effective tool management and strategies to maximize tool life are crucial.

- Process Optimization: Achieving optimal results requires careful optimization of drilling parameters, which can be complex and time-consuming.

- Quality Control and Metrology: Measuring and inspecting micro-features requires specialized metrology equipment and techniques.

- Maintaining Clean room Standards: Integrating and operating CNC drilling equipment within clean room environments requires careful planning and adherence to strict protocols.

The Future Outlook for Micro-Precision CNC Drilling in Norway

The future of micro-precision CNC drilling in Norway's medical device manufacturing looks promising. Several factors point towards continued growth and adoption:

- Ongoing Miniaturization Trends: The demand for smaller and more complex medical devices is expected to continue, further driving the need for micro-precision machining capabilities.

- Advancements in Machine Technology: Continuous innovation in CNC machine design, control systems, and tooling will lead to even more precise and efficient micro-drilling solutions.

- Integration with Digital Manufacturing: The increasing adoption of Industry 4.0 principles will see micro-precision CNC machines integrated into smart factories with advanced data analytics and automation.

- Government Support for Innovation: Norway's commitment to technological advancement and high-value manufacturing is likely to support the growth of this specialized sector.

- Collaboration and Knowledge Sharing: Increased collaboration between research institutions, machine tool manufacturers, and medical device companies in Norway will foster innovation and best practice adoption.

- Focus on Sustainability: Future developments may also focus on more sustainable micro-machining processes with reduced energy consumption and waste generation.

Conclusion

Micro-precision CNC drilling is rapidly becoming an indispensable technology for Norway's medical device manufacturing sector. The demand for increasingly intricate and miniaturized medical devices is fueling the adoption of these advanced machining techniques. While challenges related to investment, skills, and process optimization exist, the benefits in terms of precision, quality, and functionality are significant. As technology continues to advance and the medical device industry in Norway remains committed to innovation, micro-precision CNC drilling is poised for continued growth and will play a crucial role in shaping the future of medical device manufacturing in the country.

Comments