Introduction

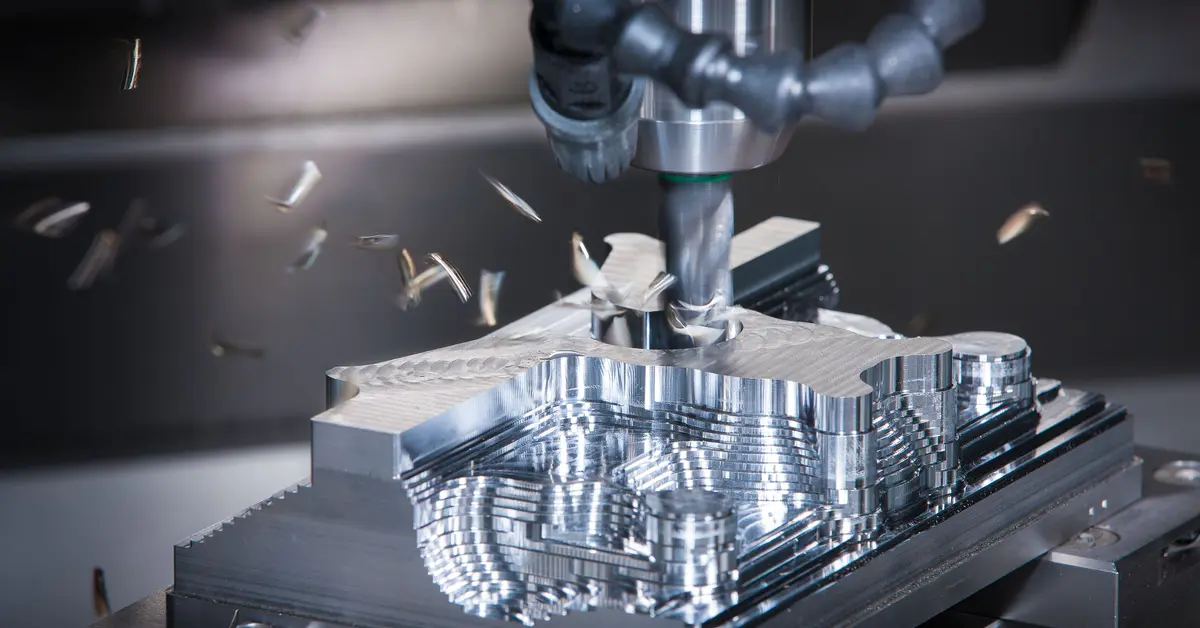

Milling machines are versatile and have become one of the most important equipment for manufacturing and other industries that rotate to remove material from a stationary workpiece to create a part. This can be performed either manually or by cutting-edge solutions (computer). However, second hand manufacturing machines are also a good option for various industries when they have a limited budget.

What Are Hand Milling Machines

A hand milling machine is a type of machinery that removes material from a workpiece. These machines perform various operations such as cutting, drilling and boring. The term milling refers to the procedure of cutting material segments parallel to the tool axis. These machines are available in different types that are being used by plastic, metal, woodwork and many other manufacturing industries.

The three major components of this machine are the spindle, holding the cutting tool in place, a worktable, and a cutting tool. ThHand milling machines are available in different varieties, such as universal, horizontal, and vertical mills, each meeting a particular need for machining.

Industries Using Hand Miling Machines

Metal Fabrication

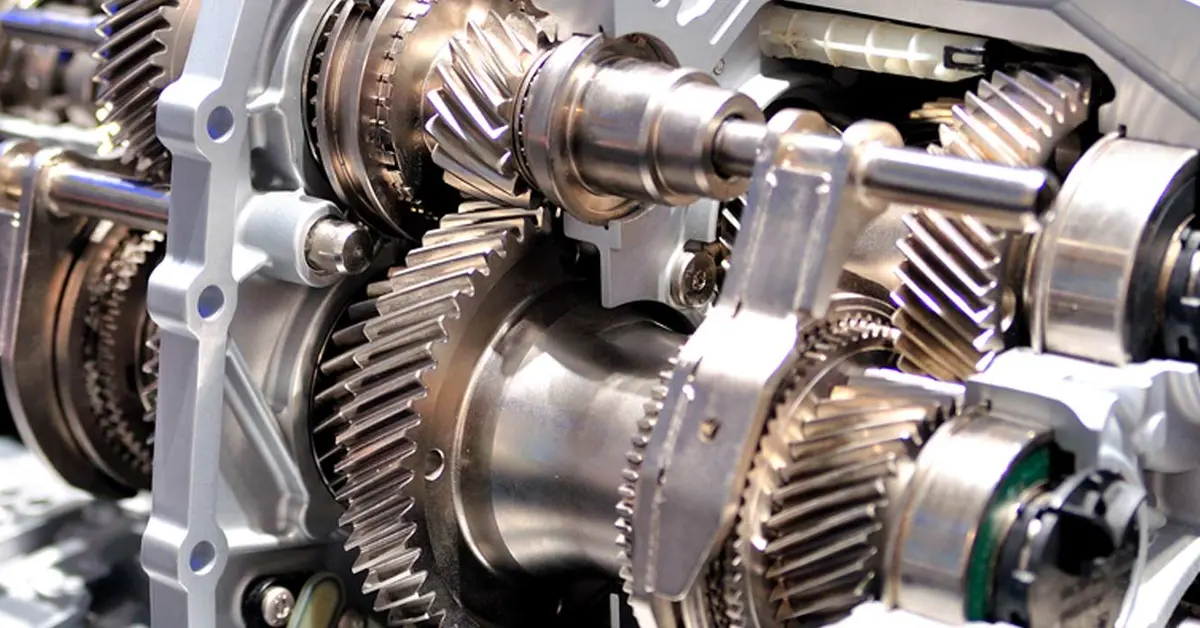

This machine type is used widely in metalworking industries for precision cuts, holes, and shaping metal components. Furthermore, automotive parts and aerospace components are manufactured with hand-milling machines.

Carpentry or Wood Working

Using hand milling machines, carpenters can craft intricate designs, creating joints and smoothing surfaces. However, manual machines allow artisans to showcase their skills and customize detailing.

Plastic Items

Industries dealing in plastic molding and fabrication often use milling machines to give plastic material a proper shape and refine it to ensure desired requirements and tolerances are met.

How Do Milling Machines Work?

Likewise, lathe milling machines show the same results when rotating the workpiece. Milling machines still hold the workpiece using a vice or fixture. However, milling machines generally use cylindrical tools, including drills and endmills, to keep away material. They can also work on uneven surfaces but are primarily used on flat surfaces. You can sell machine further to someone if they are outdated, old, and not manufacturing up-to-date parts.

What Are the Advantages of Hand Milling Machines?

Cost-Effective

Hand milling machines are cost-effective and more affordable than those used to cut and drill strong solid materials, usually metal, through milling. These machines make the work easier for smaller businesses and workshops.

Flexibile

The manual operation system allows operators to adapt to changing requirements and handle diverse materials effectively.

Precision

Utilizing hand milling machines, skilled operators can achieve high precision when performed by skilled personnel, enabling them to perform more complex tasks and fine craftsmanship.

Conclusion

Choosing the suitable types of machines for manufacturing intricate parts seems like a challenging task. Milling machines are available in various types, making it difficult to select one among them. However, getting the right machine for performing, manufacturing, operating or refining plastic parts or automotive components is important. Have a look at the wide range of used sheet metal equipment for sale, including milling machines, for cost-effective solutions without compromising on quality.

Comments