The Backbone of Manufacturing: Reliability and Regulatory Compliance as an Industrial Chemical Supplier USA 🧪

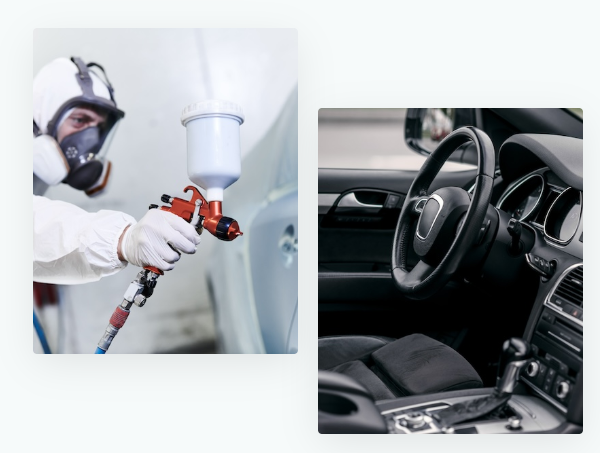

The modern manufacturing sector in the United States is fundamentally reliant on a steady, high-quality, and fully compliant stream of raw and finished materials. The role of the industrial chemical supplier USA is central to this stability, providing not just bulk chemicals and specialized formulations—such as high-performance industrial coatings—but also the critical specialized knowledge and logistical support necessary for large-scale, uninterrupted production. An industrial chemical supplier that focuses on advanced surface treatments serves as a crucial strategic partner, ensuring that client operations—from furniture finishing and automotive component assembly to structural steel protection—are never halted by a shortage, quality inconsistency, or regulatory issue with their essential chemical inputs. Their expertise covers everything from managing complex product safety data to ensuring timely, cost-effective, and safe delivery across the vast geographical expanse of the continent.

A reliable industrial chemical supplier must excel in two non-negotiable areas: product integrity and regulatory compliance. Product integrity means ensuring absolute consistency in chemical composition, purity, and performance from batch to batch, a critical requirement for OEMs running precision, automated lines where even minor variations can lead to widespread defects. The supplier achieves this through stringent quality control protocols, advanced in-house testing labs, and certified manufacturing processes (such as ISO standards). Regulatory compliance involves the complex and critical task of ensuring all chemicals are handled, stored, transported, and documented in strict accordance with federal and state regulations, including those from OSHA (worker safety), EPA (environmental), and DOT (transportation). This level of diligence protects the client from potential operational shutdowns, significant fines, environmental incidents, and severe worker safety risks associated with chemical handling. The supplier acts as the client’s expert partner in navigating these often-overwhelming compliance requirements, often providing on-site training and necessary documentation.

Furthermore, a specialized chemical supplier often serves as a source of technical innovation, helping clients integrate the latest material science breakthroughs into their production process. This might involve proactively introducing safer, more sustainable alternatives (like low-VOC waterborne systems) that help clients get ahead of impending air quality regulations, or optimizing the chemical specifications of a product for better performance within the client’s unique manufacturing conditions. This technical agility is what differentiates a simple distributor from a true partner. By maintaining cutting-edge Research & Development capabilities, the supplier is able to offer custom formulations that solve specific adhesion, durability, or application challenges that generic, off-the-shelf products cannot address. This commitment to ongoing Expertise and Experience ensures the client's products maintain a competitive edge in performance and sustainability.

The logistical challenge faced by an industrial chemical supplier USA is immense, requiring specialized infrastructure for warehousing and transport. They must manage the risks associated with bulk hazardous materials, often utilizing specialized trucks, secure storage tanks, and managing the temperature sensitivity of modern waterborne coatings across varying climates. This specialization relieves the manufacturing client of the burden of complex chemical logistics, storage, and material safety documentation, allowing them to focus entirely on their core competency. Partnering with a proven industrial chemical supplier USA means gaining access to highly reliable, documented, and consistently produced materials backed by a robust, localized supply chain. This relationship is a critical foundation for maintaining high efficiency, minimizing operational risk, and fostering continuous improvement in manufacturing processes across various industrial sectors.

Finally, in the competitive B2B landscape, the Trustworthiness of a supplier is measured by their commitment to long-term partnerships and supply chain resilience. The ability to guarantee a continuous supply, even during periods of raw material scarcity or global disruption, is paramount. A domestic supplier provides a clear advantage in supply chain security over international sources, reducing lead times and minimizing exposure to global trade volatility. The relationship is not just about the transaction; it is about providing the technical and logistical foundation upon which an entire manufacturing business can reliably operate and grow. This high level of service ensures the chemical materials function exactly as required, day after day, year after year.

Comments