Explosion prevention systems are critical safety mechanisms used across various industries to reduce the risk of catastrophic explosions. Whether it’s in manufacturing, chemical processing, or mining, controlling explosive hazards can save lives, protect infrastructure, and preserve business continuity. In this blog, we will explore different explosion prevention techniques, their importance, and how they work to keep dangerous environments under control.

What Are Explosion Prevention Systems? 💥

Explosion prevention systems are engineered safety measures designed to prevent the occurrence of an explosion or mitigate its impact. They are commonly used in environments where there is a presence of flammable gases, dust, or vapors. By either controlling the potential for ignition or containing the explosion, these systems help minimize damage to equipment, facilities, and personnel.

Explosion prevention is distinct from explosion protection, which focuses on how to mitigate the impact of an explosion once it occurs. Prevention, however, aims to eliminate the possibility of an explosion before it even starts.

Why Are Explosion Prevention Systems Important? 🔥

Protecting Lives 👷♂️👷♀️

The most crucial reason to implement explosion prevention systems is the safety of employees and anyone in the vicinity. Explosions can cause severe injury, loss of life, and trauma. Prevention strategies ensure the workplace remains safe for workers.

Minimizing Property Damage 🏭

The financial impact of an explosion can be devastating. Explosions destroy equipment, infrastructure, and entire facilities, leading to high repair and replacement costs. With proper prevention, companies can avoid these catastrophic losses.

Compliance with Regulations 📜

Industrial facilities are subject to stringent safety regulations to ensure the health and safety of workers. Explosion prevention systems help companies comply with standards such as OSHA, NFPA, and ATEX (in the European Union), avoiding fines and legal issues.

Continuity of Operations 🔄

Even a minor explosion can halt operations for weeks or months. By preventing explosions, businesses ensure that their production processes continue without costly interruptions. This helps maintain a steady flow of goods and services.

Key Types of Explosion Prevention Systems ⚙️

1. Explosion-Proof Equipment 🚨

Explosion-proof equipment is designed to withstand internal explosions without causing ignition outside the equipment. These systems are typically used in areas where there is a high risk of explosive gases, such as oil rigs, chemical plants, and mining facilities.

- Enclosures: Explosion-proof enclosures house electrical equipment and ensure that any sparks or heat generated by the equipment are contained within.

- Flame Arresters: These devices are used to stop flames from traveling through pipes or vents, preventing the spread of combustion.

2. Inerting Systems 🌬️

Inerting systems work by replacing oxygen with non-combustible gases such as nitrogen or carbon dioxide. By reducing the oxygen concentration below the level required for combustion, these systems prevent the risk of explosion.

- Inert Gas Generation: On-site inert gas generators produce nitrogen to displace oxygen in the atmosphere.

- Inerting of Hazardous Materials: In some cases, materials like fuels or chemicals are stored under inert conditions to prevent ignition.

3. Venting and Deflagration Relief Systems 💨

Venting systems are used to release pressure and gases that could lead to an explosion. When an ignition occurs, the venting system allows the rapid escape of hot gases and flames to prevent a full-scale explosion.

- Explosion Vents: These are designed to open at a predetermined pressure, allowing the release of gases before the pressure reaches dangerous levels.

- Flame Arrestors and Dampers: They are installed on vents to stop flames from escaping.

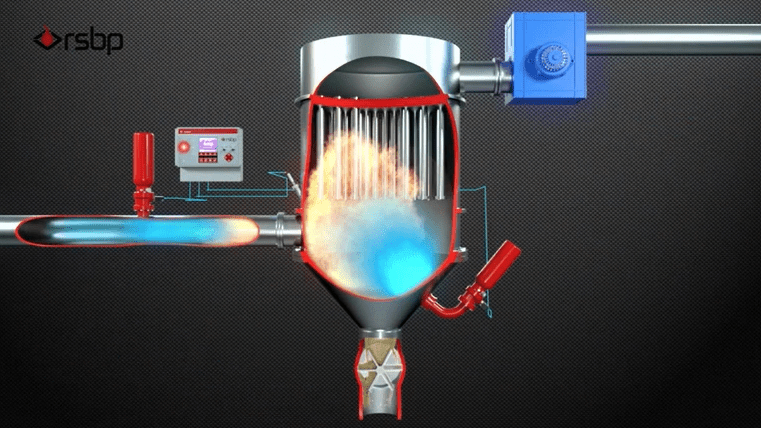

4. Spark Detection and Extinguishing Systems 🔥🛑

Spark detection systems are used in environments where sparks could lead to an ignition. These systems detect sparks early and extinguish them before they can cause a dangerous situation.

- Detection Units: These sensors detect sparks or hot particles in ducts, conveyors, or exhaust systems.

- Extinguishing Units: Once sparks are detected, extinguishing systems are activated using water, CO2, or other fire suppression agents.

5. Dust Explosion Prevention 💨

Dust is a common hazard in industries like agriculture, woodworking, and food processing. In the right conditions, dust can ignite and cause a massive explosion. Dust explosion prevention systems are designed to prevent the accumulation of dust particles that could cause ignition.

- Dust Collection Systems: These systems remove dust from the air before it can accumulate in hazardous amounts.

- Explosion Isolation: This prevents dust explosions from spreading to other parts of the facility by isolating the affected area.

Key Components of an Explosion Prevention System 🔧

Explosion prevention systems rely on multiple components that work together to ensure safety. Here are some of the most common components:

1. Sensors and Detectors 🛠️

- Gas Detectors: These sensors detect the presence of flammable gases or vapors in the air.

- Temperature Sensors: These monitor the temperature of equipment and areas prone to overheating.

- Pressure Sensors: Pressure gauges help to identify abnormal increases in pressure, which could indicate the potential for an explosion.

2. Control Systems 🖥️

Explosion prevention systems often include control panels that monitor various parameters, such as temperature, pressure, and gas concentration. These systems can trigger safety measures, such as shutting down equipment or activating extinguishing systems.

3. Mechanical Safety Devices ⚙️

- Explosion Relief Valves: These devices relieve excess pressure caused by an explosion.

- Flame Arrestors: Prevent flames from spreading through pipes or ducts.

- Explosion Isolation Valves: These valves isolate parts of the system to prevent the propagation of explosions.

4. Fire Suppression and Extinguishing Systems 🔥🚿

When prevention measures fail, fire suppression systems are the last line of defense. These systems use various agents, such as foam, water, CO2, or dry chemicals, to extinguish fires and limit damage.

- Water Mist Systems: Fine water droplets cool the surrounding area, limiting the spread of flames.

- CO2 Systems: These remove oxygen from the air, suffocating the fire.

How Do Explosion Prevention Systems Work? 🛠️

1. Detection of Hazards ⚠️

The first step in preventing an explosion is detecting potential hazards. This is done by constantly monitoring the atmosphere for dangerous levels of combustible gases, vapors, or dust. Sensors alert control systems when thresholds are exceeded, triggering automatic shutdowns or activation of protective measures.

2. Reducing the Risk of Ignition 🔥

Once a potential hazard is detected, the next step is to eliminate or reduce the risk of ignition. Explosion-proof equipment ensures that sparks or hot surfaces don’t ignite flammable materials. Inerting systems reduce the oxygen level, making it impossible for combustion to occur.

3. Venting and Containment 💨

Venting systems are activated to release any pressure buildup, preventing the formation of an explosive atmosphere. In case of ignition, deflagration relief systems, including flame arrestors, contain the explosion within a controlled space.

4. Suppression and Extinguishing 🔥🛑

If an explosion occurs, fire suppression systems come into action. They work to contain the fire or explosion by removing oxygen, cooling the area, or suppressing the fire with chemicals.

Conclusion: Investing in Safety 🛡️

Explosion prevention systems are indispensable in hazardous industries. By taking proactive steps to identify, control, and eliminate risks, these systems save lives, protect assets, and ensure regulatory compliance. Businesses that invest in these systems benefit from increased safety, reduced downtime, and enhanced operational efficiency.

Implementing a combination of explosion-proof equipment, inerting systems, venting, dust control, and fire suppression ensures a comprehensive safety approach. The importance of explosion prevention cannot be overstated—safety should always come first. 🚨

Contact Us Today!

Business Address: 21 Ellis Street, London SW1X9AL

Business Phone: +44 208-2438-914

Hours of Operations: 9am til 5pm Monday - Friday

Comments