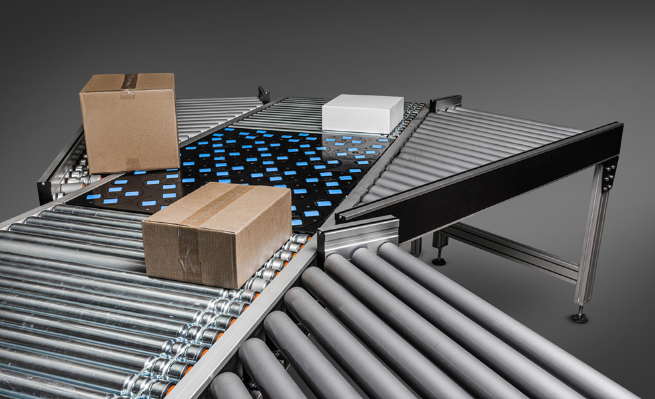

Diverter sorters are integral components in intelligent sorting systems. They are designed to redirect items from one conveyor line to another, directing goods to their intended destinations based on preset criteria. A diverter sorter uses mechanical or pneumatic methods to "divert" items off the main track, enabling precise sorting without manual intervention.

In modern industries, where high volumes of goods need to be sorted quickly and accurately, diverter sorters are a key technology that ensures efficiency. They can handle a variety of items, from parcels to smaller packages, providing significant automation in the sorting process.

Duties and Responsibilities of a Diverter Sorter

The duties of a diverter sorter are critical to the overall functioning of a sorting system. These duties can be categorized into several key responsibilities:

- Sorting and Diverting Packages

The primary duty of a diverter sorter is to sort and divert packages or items based on specific criteria, such as destination, size, or type of product. This is usually accomplished using a combination of conveyors, sensors, and control systems that determine where each item should go. Diverter sorters are equipped with mechanisms that allow for quick and accurate redirection of items without slowing down the system.

- Ensuring Efficient Flow

A diverter sorter’s responsibility also includes ensuring that items flow smoothly throughout the sorting system. This means monitoring conveyor speeds, making real-time adjustments, and ensuring that there are no blockages or delays in the system. By controlling the flow of goods, diverter sorters help maintain efficiency and reduce downtime.

- Minimizing Errors and Accidents

Since diverter sorters are used to handle large volumes of goods, minimizing errors is crucial. One of the duties of a diverter sorter is to make sure that the right items are diverted to the right destinations. This is often done through the use of advanced sensors and imaging systems that provide real-time feedback on item placement. The sorter must avoid accidents or misdirected goods, as errors can disrupt the entire supply chain.

- Integrating with Other Systems

Diverter sorters are often part of larger sorting systems, where they need to integrate seamlessly with other components, such as conveyors, scanners, and even automated storage systems. The sorter’s job includes ensuring that these various components work together harmoniously to ensure the smooth operation of the entire sorting system. This requires careful planning, communication, and synchronization between devices and control systems.

- Handling Various Item Types

Different types of products may need to be diverted in different ways. Diverter sorters are often equipped with the flexibility to handle various sizes, shapes, and weights of items, making them versatile in multiple applications, from retail to logistics. Diverter sorters must also adjust their speed and sorting mechanisms based on the size and characteristics of the product.

Applications of Diverter Sorters in Industries

Diverter sorters are utilized across a range of industries that require efficient, automated sorting systems. Here’s a look at the sectors where diverter sorters are commonly employed:

- Retail and E-commerce

The retail and e-commerce sectors are the biggest beneficiaries of diverter sorter systems. With the rise of online shopping, retailers need to sort thousands of packages daily, often based on delivery addresses or customer orders. Diverter sorters are essential in these environments for quickly and accurately redirecting parcels to their respective areas for final delivery.

In e-commerce fulfillment centers, diverter sorters can handle items of all sizes, from small packets to large, bulky items, efficiently directing them to packing areas or delivery zones. This helps streamline the entire fulfillment process.

- Logistics Operators

Logistics operators and distribution centers rely heavily on diverter sorters to manage high volumes of parcels and packages. These sorters help in sorting goods quickly and accurately, improving the overall speed of delivery and ensuring that the right items reach their correct destinations. With the rise of smart logistics, diverter sorters have become a key component in intelligent sorting systems.

- Courier Express Parcels

Courier services, which deliver parcels to customers quickly, also benefit greatly from diverter sorters. By automating the sorting process, these companies can handle large volumes of packages efficiently. Diverter sorters help improve delivery speed, reduce errors, and provide higher customer satisfaction, which is critical in the fast-paced world of courier services.

Technologies Behind Diverter Sorters

Diverter sorters are equipped with advanced technologies to ensure high efficiency and accuracy. Some of the key technologies include:

- Automation and Control Systems

Diverter sorters use automation systems to control the flow of goods. These systems are often integrated with sensors, scanners, and imaging devices that allow the sorter to identify items and decide where to direct them. The use of advanced software allows for real-time control, ensuring that the sorter functions seamlessly within the broader sorting system.

- Sensors and Imaging

Sensors and imaging technologies are critical to the operation of diverter sorters. These devices scan items to determine their size, shape, and destination, ensuring they are diverted to the correct conveyor or destination area. This allows for precision sorting, minimizing errors and increasing efficiency.

- Advanced Materials

Many modern diverter sorters are made from high-quality, durable materials that can withstand the rigors of continuous operation. The materials used are selected for their ability to handle different types of packages, and many sorters are built to be resistant to wear and tear.

Benefits of Diverter Sorters in Modern Sorting Systems

The integration of diverter sorters in modern sorting systems offers a number of benefits:

- Increased Efficiency

Diverter sorters help streamline sorting processes, increasing overall operational efficiency. With high-speed sorting capabilities, these sorters can handle large volumes of items, ensuring quick and accurate redirection.

- Reduced Labor Costs

By automating the sorting process, diverter sorters reduce the need for manual labor, which helps lower operational costs. This is particularly beneficial in high-volume environments, where human error can result in significant delays and inaccuracies.

- Improved Accuracy

With sensors and control systems, diverter sorters ensure precise sorting, reducing the chances of misdirected goods. This improved accuracy leads to higher customer satisfaction and better overall system performance.

Conclusion

Diverter sorters are crucial in modern sorting systems, providing industries like retail, logistics, and e-commerce with efficient, accurate, and cost-effective solutions for handling goods. These sorters’ duties range from sorting packages based on size or destination to integrating seamlessly with other parts of a sorting system. As technology continues to advance, diverter sorters are evolving to meet the increasing demands of fast-paced, high-volume industries.

Dijie’s intelligent sorting solutions incorporate cutting-edge diverter sorters to enhance the efficiency of modern supply chains. With their ability to handle various types of goods and integrate with other advanced technologies, diverter sorters are playing a pivotal role in shaping the future of logistics and distribution systems.

Comments