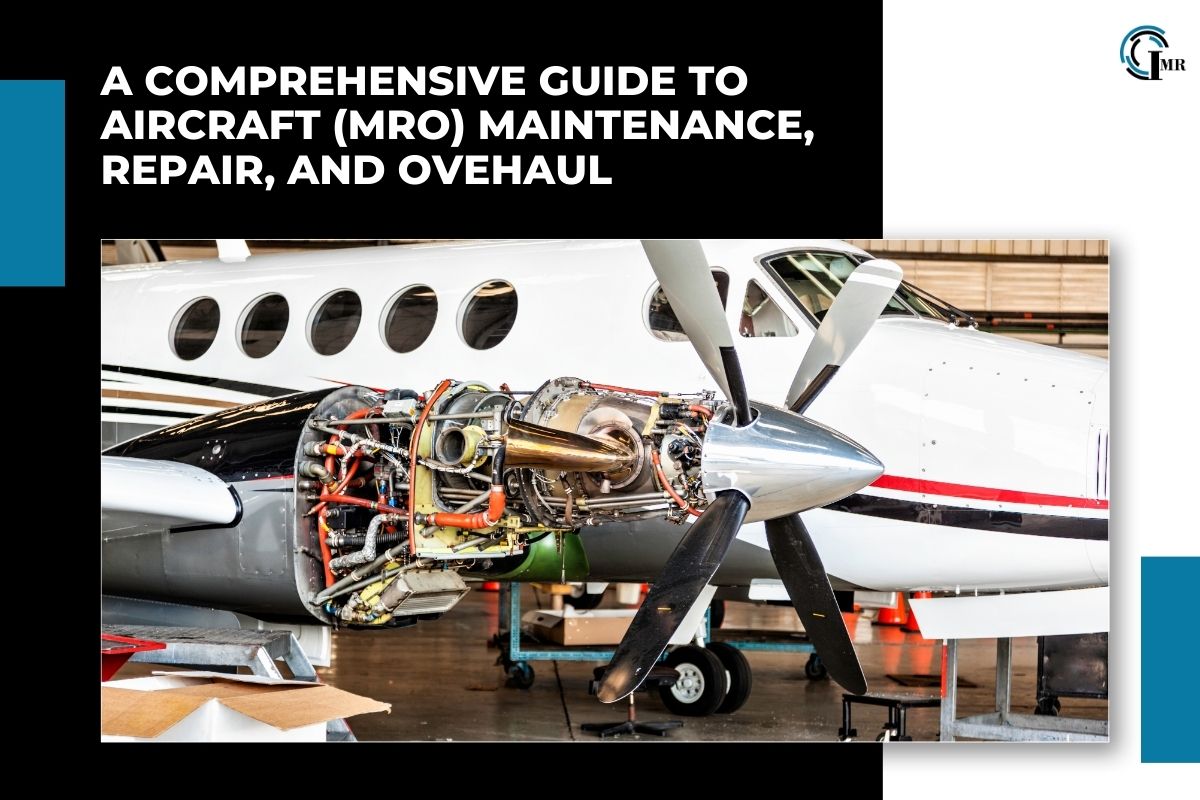

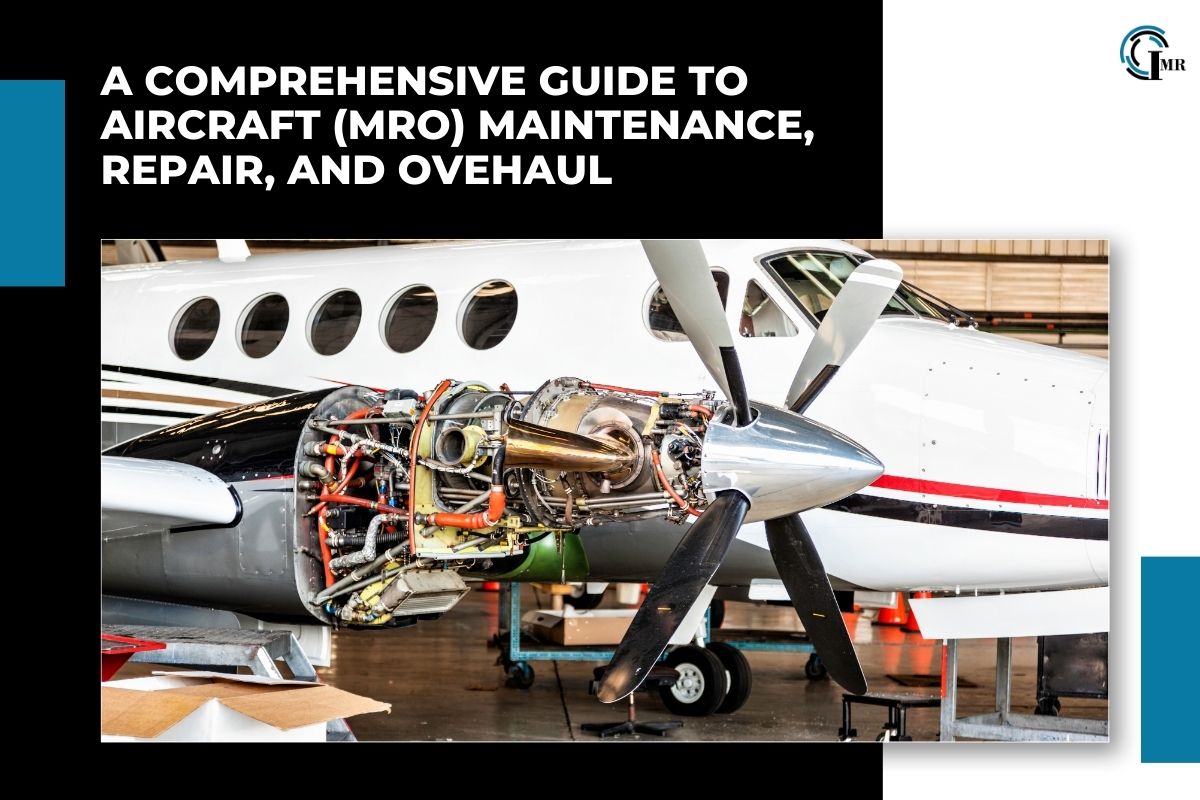

A Comprehensive Guide To Aircraft (MRO) Maintenance, Repair And Ovehaul

In the aviation industry, safety is paramount, and the reliability of aircraft is non-negotiable. Aircraft Maintenance, Repair, and Overhaul (MRO) is the cornerstone of aviation safety, ensuring that aircraft remain in airworthy condition throughout their operational lifespan. In this article, we delve into the world of Aircraft MRO, exploring its importance, key processes, challenges, and future trends shaping the industry.

Importance of Aircraft MRO:

Aircraft Maintenance, Repair, and Overhaul (MRO) encompass a range of activities aimed at ensuring the airworthiness and operational integrity of aircraft. These activities are crucial for several reasons:

- Safety: The primary goal of Aircraft MRO is to uphold safety standards and prevent accidents by maintaining aircraft in optimal condition. Regular inspections, repairs, and component replacements are essential to identify and rectify potential safety hazards before they compromise flight operations.

- Reliability: Commercial airlines rely on the reliability of their fleet to maintain schedules, meet customer expectations, and safeguard their reputation. Effective MRO practices help minimize unscheduled maintenance events and ensure aircraft availability when needed.

- Regulatory Compliance: Aviation authorities, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), impose stringent regulations and guidelines on aircraft maintenance to ensure compliance with safety standards. MRO providers must adhere to these regulations to maintain their operating certifications.

- Cost Management: Efficient aircraft MRO operations can significantly impact the cost-effectiveness of airline operations. Proactive maintenance strategies, predictive analytics, and inventory optimization help minimize downtime, reduce maintenance costs, and extend the operational lifespan of aircraft.

Key Processes in Aircraft MRO:

Aircraft Maintenance, Repair, and Overhaul (MRO) encompass a diverse range of activities, including:

Line Maintenance:

- Line maintenance involves routine inspections, servicing, and minor repairs performed on aircraft between flights or during layovers at airports.

- Trained maintenance technicians conduct visual checks, system tests, and component replacements to ensure aircraft are airworthy and compliant with regulatory requirements.

Base Maintenance:

- Base maintenance encompasses more extensive maintenance tasks, including scheduled inspections, repairs, and modifications that require aircraft to be taken out of service for an extended period.

- These activities may include engine overhauls, structural repairs, avionics upgrades, and interior refurbishments conducted in dedicated maintenance hangars equipped with specialized tools and equipment.

Component Maintenance:

- Component maintenance involves the repair, overhaul, and testing of individual aircraft components, such as engines, landing gear, flight control systems, and avionics.

- Specialized repair facilities, known as Component Repair Shops (CRS), perform in-depth inspections, troubleshooting, and refurbishment of components to restore them to airworthy condition.

Engine Overhaul:

- Engine overhaul is a critical aspect of aircraft maintenance, involving the disassembly, inspection, repair, and reassembly of aircraft engines to ensure optimal performance and reliability.

- Skilled technicians and engineers follow manufacturer specifications and rigorous quality control processes to overhaul engines and replace worn or damaged parts.

Challenges in Aircraft MRO:

Despite its importance, Aircraft Maintenance, Repair, and Overhaul (MRO) face several challenges:

Technological Complexity:

- Modern aircraft features advanced avionics, composite materials, and digital systems that require specialized skills and equipment for maintenance and repair.

- MRO providers must invest in training programs and technology upgrades to keep pace with technological advancements and ensure competency in handling complex aircraft systems.

Cost Pressures:

- Aircraft MRO operations are subject to cost pressures driven by factors such as fuel prices, labor costs, regulatory compliance, and competition.

- Aircraft MRO providers must balance the need for cost-effective solutions with maintaining high-quality standards and safety compliance to remain competitive in the market.

Supply Chain Disruptions:

- Global supply chain disruptions, such as material shortages, logistics delays, and geopolitical tensions, can impact the availability of critical components and spare parts for aircraft maintenance.

- MRO providers must adopt robust supply chain management strategies, diversify sourcing options, and maintain strategic inventory reserves to mitigate supply chain risks.

Regulatory Compliance:

- Compliance with regulatory requirements is paramount in aircraft maintenance to ensure airworthiness and safety.

- Aircraft MRO providers must navigate complex regulatory frameworks, undergo regular audits, and stay updated on evolving aviation regulations to maintain certification and accreditation.

Future Trends in Aircraft MRO:

Despite the challenges, several trends are shaping the future of Aircraft Maintenance, Repair, and Overhaul (MRO):

Digital Transformation:

- Digital technologies, such as predictive maintenance, IoT sensors, and data analytics, are transforming MRO operations, enabling proactive maintenance strategies, real-time monitoring, and predictive insights.

- AI-driven predictive analytics and machine learning algorithms help forecast equipment failures, optimize maintenance schedules, and reduce downtime.

Additive Manufacturing:

- Additive manufacturing, or 3D printing, is revolutionizing aircraft component manufacturing and repair by enabling rapid prototyping, on-demand part production, and cost-effective repairs.

- MRO providers are leveraging additive manufacturing techniques to produce complex components, reduce lead times, and enhance fleet readiness.

Augmented Reality (AR) and Virtual Reality (VR):

(Source – Netherlands Aerospace Centre)

(Source – Netherlands Aerospace Centre)

- AR and VR technologies are enhancing training programs, remote assistance, and maintenance procedures by providing immersive, interactive experiences for technicians.

- Technicians can access digital manuals, overlay virtual instructions, and visualize equipment configurations in real-time, improving efficiency and accuracy in MRO tasks.

Conclusion:

Aircraft Maintenance, Repair, and Overhaul (MRO) are critical functions in ensuring the safety, reliability, and airworthiness of aircraft. By implementing effective maintenance strategies, leveraging advanced technologies, and addressing key challenges, MRO providers can optimize operations, enhance safety standards, and meet the evolving needs of the aviation industry. With digital transformation, additive manufacturing, and augmented reality shaping the future of aircraft MRO, the industry is poised for innovation and growth in the years to come.

Comments