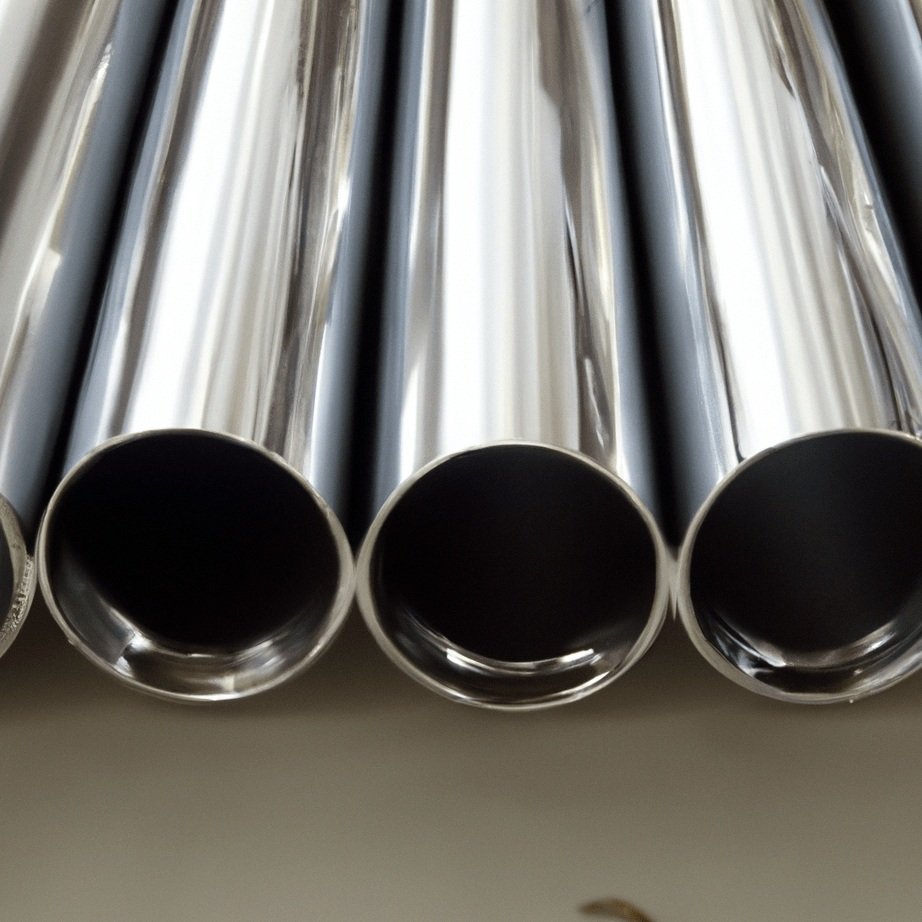

Infrastructure development relies heavily on high-quality materials such as MS pipes, MS pipe fittings, and forged pipe fittings. These components ensure structural integrity and longevity, making them indispensable in construction, oil and gas, and water supply industries.

Brands like Jindal Hissar pipes, Jindal SS pipes, and Jindal Star pipes have set the benchmark in the piping industry. Additionally, Maharashtra seamless pipes are preferred for their superior strength and resistance to wear and tear.

This blog delves into the role of MS pipes, their pricing factors, and how forged pipe fittings enhance modern infrastructure.

The Advantages of MS Pipes in Infrastructure

MS pipes are widely used due to their cost-effectiveness, versatility, and durability. They are ideal for applications such as:

- Water supply systems – Ensuring leak-proof transport of potable water.

- Construction frameworks – Used as structural supports in buildings and bridges.

- Gas pipelines – Resistant to high-pressure transport systems.

When choosing MS pipes, factors such as brand reputation, quality assurance, and pricing play a crucial role in decision-making.

Understanding MS Pipe Prices Per Kg

The MS pipe prices per kg vary based on the material grade, manufacturing process, and coating applied for corrosion resistance. Jindal Hissar pipes and Jindal SS pipes are known for their affordability without compromising strength.

If you're looking for premium-quality pipes, Maharashtra seamless pipes provide a superior alternative. These pipes are manufactured without welds, making them stronger and more reliable in demanding applications.

Importance of MS Pipe Fittings and Flanges

To build a strong and efficient pipeline system, investing in high-quality MS pipe fittings and Unik pipe fittings is essential. These fittings provide:

- Leak-proof connections – Preventing costly maintenance and repairs.

- High-pressure resistance – Ensuring performance under extreme conditions.

- Longevity – Reducing frequent replacements and associated costs.

Similarly, MS flanges allow for easy disassembly and maintenance of pipelines. Whether for industrial use or residential plumbing, MS flanges ensure secure connections between pipes.

The Role of Forged Pipe Fittings in Industrial Applications

Forged pipe fittings are manufactured under extreme pressure, making them stronger than cast fittings. They are widely used in industries such as:

- Oil and gas – Ensuring secure and pressure-resistant pipelines.

- Chemical processing – Providing corrosion resistance against harsh substances.

- Heavy machinery – Used in hydraulic and pneumatic systems.

The strength and durability of forged pipe fittings make them an excellent investment for long-term infrastructure projects.

Conclusion

Selecting the right MS pipes, MS pipe fittings, and forged pipe fittings ensures the longevity and efficiency of infrastructure projects. With leading brands like Jindal Hissar pipes, Jindal SS pipes, and Jindal Star pipes, you can be assured of quality and durability. Understanding MS pipe prices per kg and choosing Maharashtra seamless pipes can make a significant difference in project costs and efficiency.

By investing in high-quality MS flanges, forged pipe fittings, and Unik pipe fittings, businesses and individuals can ensure that their pipelines remain strong, durable, and efficient for years to come.

Comments