Elevation of Quality Control: The top reasons to invest in a Torque tester for your lab

Product quality and manufacturing accuracy depend largely on the torque to ensure the functionality as well as reliability of various mechanical and electronic components. Be it the bolt of any automobile assembly or the cap for the machine that seals caps, the measurement of torque must be made and then accurately controlled. This is where the torque tester comes to add inputs. Torque testing ensures your products meet the required torque specifications, which in turn reduces the possibility of product failures and makes a business more safe and efficient in total. In this blog, we will explain why torque testing is significant, introduce the torque tester, discuss the ROI that can be expected from putting a torque testing machine in your laboratory, and point out some of the top models from Presto, a leading testing equipment manufacturer.

Why Torque Testing?

Therefore, torque testing is highly important in industries such as automotive, aerospace, electronics, and packaging that require high précised tightening. Torque is a rotational force applied to an object, and if it drops or increases beyond the set limits, several operational problems arise.

Product failures: A fastener or component that over-tightens or under-tightens could make the product malfunction or fail early.

Safety risks: In various applications like aerospace or automotive, due to improper torque, there may be the risk of safety-critical failures with possible injuries to consumers and workers.

Operational inefficiency: Torque misapplication can lead to rework, production delays, and wastage of materials.

Quality control consistency: The quality of the product will not be uniform as intended since the quality control will remain uncertain if torque testing is not properly done.

A digital torque tester or a torque testing machine is actually necessary to ensure that your products meet the standards of high quality and industry regulations. These machines keep in check the accuracy of the assembly process and serve to guarantee product of reliability and prevent cost-prohibitive mistakes.

Introducing Torque Tester

Torque testers range from digital to mechanical torque testers. Manufacturers can use these machines to ensure the proper application of torque when assembling.

Torque testers have accurate sensors and digital readouts for easy measurement of values. They can test fasteners, caps, valves, and even handheld tools for consistency in torque. Now, they have become a necessity in any testing laboratory as the quality control requirements continue to grow.

Why Presto Torque Testers?

Presto has led in the supply of high-class testing instruments for almost every industry worldwide. With years of expertise and innovations, Presto has emerged as a leading supplier of reliable and accurate testing machines such as torque testers. Combining advanced technology, precision engineering, and user-friendliness, Presto torque testers offer total solutions to businesses demanding strict quality control.

From automotive parts and consumer goods to packaging materials, Presto has the most advanced torque testers to make sure your products meet the required torque specification and international standards.

Benefits of a Digital Torque Tester

The involvement of a torque tester in the business can provide long-term advantages. Some key ROI factors that businesses enjoy once they integrate torque testers into their labs are as follows:

Reduced product failures: Under- or over-tightening of fasteners and components is reduced on account of perfect torque control, therefore minimizing product recalls as well as failures. In fact, based on research, the enhancement in torque control can decrease up to 30% of product failures.

Cost Savings on Rework and Scrap: If torque application errors are caught early, then labour costs, as well as material wastage, will be considerably reduced. Businesses could save up to 20% each year in rework costs if a torque testing solution is implemented.

Increased Operational Efficiency: Your team will perform consistent and accurate torque testing because of a torque tester in less time as compared to when they relied on manual methods. Your overall production efficiency increases by 15-20%.

Compliance Standards: Torque testing becomes mandatory for various industries to be under the standard requirements of ASTM, ISO, and FDA. A torque tester will enable you to maintain conformity to these standards, and you avoid penalties and fines.

Reduced Warranty Claims: By using a torque tester from us, you can save a loss of up to 15% in warranty. Your products have more chances of meeting quality expectations.

Companies can easily recover the cost incurred in a torque testing machine due to several cost savings and quality improvement advantages yielded by these systems within the first year of usage.

Presto Torque Tester Models

Presto offers a variety of torque testers designed to suit different testing needs. Below, we will highlight some of the most popular models, along with their specifications, ASTM standards, and features.

Torque Tester – Digital

Technical Specification:

- Accuracy: ± 0.5 lb-Inch (with master weight)

- Least Count/Resolution: 0.1 lb-inch

- Power: 220V, Single phase, 50 Hz

- Display: Digital (LED) 7-segment display

- Torque Monitoring: Peak Load indicator with Digital readout

- and peak hold feature

- Minimum Diameter for specimen holding: 30 mm

- Maximum Diameter for specimen holding: 110 mm

- Weights for Calibration: 10 lbs, 20 lbs (optional parts)

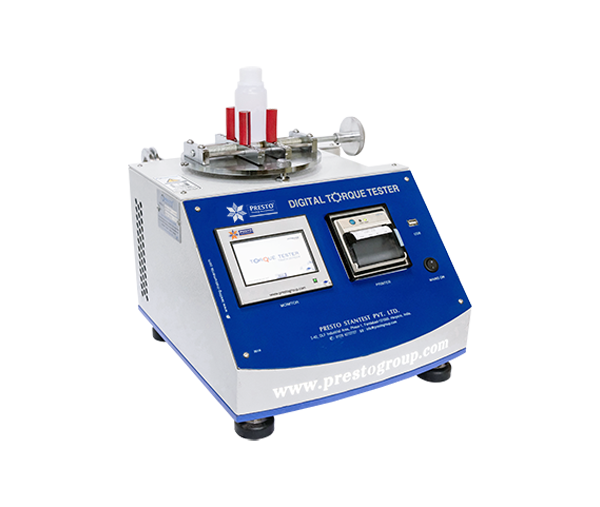

Torque Tester - Prima (Touch Screen with Printer)

Technical Specification:

- Max. Torque Range: 100 lb- inch

- Accuracy: ± 0.5 lb-Inch (with master load)

- Least Count/Resolution: 0.01 lb- inch/ 0.01 kg.cm/0.01 Nm

- Power: 220V, Single phase, 50 Hz

- Display: HMI TFT Screen 4.3 Inch

- Torque Unit: lb Inch / Nm

- Minimum Diameter for specimen holding: 20 mm

- Maximum Diameter for specimen holding: 130 mm

- Max. size of test bottles to be tested: 2.5 litres.

- Sample Size: Min. height 25 mm

- Anti-vibration pad: Specially designed to reduce the effect of the vibration

- Safety: Yes (overload protection)

Torque Tester HMI Motorised

Technical Specification:

- VNC Software for advanced security features

- Automatic retaining of peak value and recording the test results precisely

- Intelligent design of overload protection, automatic Zeroing and error alert for safe test operation.

- Equipped with USB port & RJ 45 Port which is convenient to the data transmission USB and PC connection R 485.

- Automatic data storage and power failure memory functions.

- New patented Software Intelligent touch operating system.

- Industrial grade touch screen, one button operation, user-friendly interference.

- Test curves are displayed in real time, and intelligent data statistics support a quick review of test results.

- Large storage can save 9999 of test data.

- Multiple units can be switched with each other (Nem, KGfscm, Lbin )

- Use USB interface and PC Communications synchronous test function can connect to the computer, computer synchronous display

- Pass/ fail criteria can be fed by the user (upper and lower limit value setting update in the report.

- Servo Motor Driven system with a constant rate of travel.

- Motorized drive for repeatable movements.

- Calibration with traceable reference weights.

- Quick change cap adapter, Universal or custom-made to the specific shape of a cap.

- Large HMI Display, easy to read.

- Statistical analysis of results per batch of samples is produced and then incorporated, together with graphs.

- A Motorized drive ensures repeatability and highly accurate turning Movements.

Torque Tester - Analogue

Technical Specifications:

- Max. Torque Range: 20 lb-inch

- Accuracy: ± 0.5 % full Scale(with master load)

- Least Count/Resolution: 1 lb-inch

- Power: Battery-operated

- Minimum Diameter for specimen holding: 30 mm

- Maximum Diameter for specimen holding: 110 mm

- Max. size of test bottles to be tested: 2.5 litres

- Weights for Calibration: 10 lbs, 20 lbs

FAQs About Torque Testers

1. How frequently should the torque tester be calibrated?

Otherwise, the equipment has to be calibrated quite often if the equipment is used extensively and severally.

2. one can use a single torque tester to measure clockwise as well as counterclockwise torques.

Yes, most of the digital as well as motorized models of torque testers provide the same measuring sensibility in both clockwise and counterclockwise directions.

3. How long does it take to conduct a torque test?

A torque test will typically be completed in under one minute. However, the actual time required will depend on the type of torque tester being used and the complexity of the test you want to complete.

Conclusion: Invest in Presto Torque Testers for Precision and Profitability

If you are seriously concerned about quality control, precision testing and long-term savings, then investing in a torque testing machine would be a very smart idea. From variety-rich, highly reliable torque testers offered by Presto, you can ensure your products meet the highest quality standards while maximizing operational efficiency and costly errors. Contact us to get various information like torque tester price, specifications etc.

Phone: +919210903903

Mail: [email protected]

.jpg)

Comments