IMARC Group, a leading market research company, has recently releases report titled “3D Printing in Healthcare Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2028.” The study provides a detailed analysis of the industry, including the global 3D printing in healthcare market size, growth, share, trends, and forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Industry Overview of 3D Printing in Healthcare Market

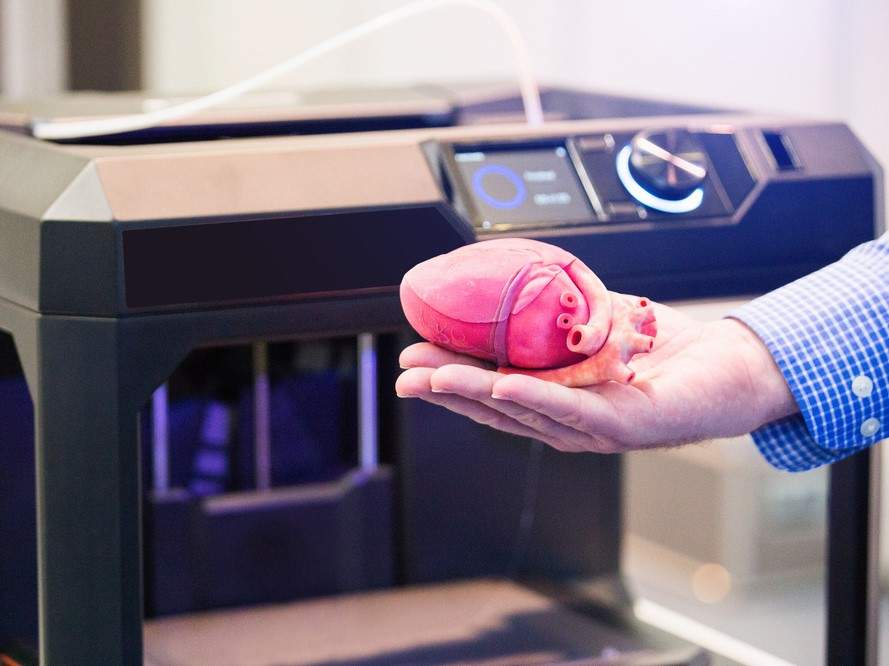

3D printing in healthcare refers to the process of producing physical objects, structures, or models layer by layer based on digital designs using a range of materials. It has the potential to create intricate and personalized medical solutions, empowering healthcare professionals to enhance patient outcomes and treatment strategies. It enables the customization of medical implants, prosthetics, and orthotics tailored to the unique anatomy of individual patients, leading to improved comfort, fit, and functionality. It fosters innovation by allowing researchers and developers to explore novel medical solutions and devices. It streamlines production processes, reducing lead times for medical device manufacturing and minimizing costs associated with customization.

How Big Is the 3D Printing in Healthcare Market?

The global 3D printing in healthcare market size reached US$ 2.6 Billion in 2022. Looking forward, IMARC Group expects the market to reach US$ 6.5 Billion by 2028, exhibiting a growth rate (CAGR) of 15.1% during 2023-2028.

What Are the Growth Prospects and Trends in The 3D Printing in Healthcare Industry?

At present, the increasing demand for 3D printing in healthcare for producing tailored medical devices and treatments to improve patient comfort, adherence, and overall outcomes, ultimately enhancing the quality of life for individuals, represents one of the crucial factors impelling the growth of the market. Besides this, the rising popularity of bioprinting, as it allows the creation of living tissues and organ-like structures which are essential for organ transplantation purposes, is contributing to the growth of the market. In addition, the increasing utilization of 3D printing in dentistry, enabling the fabrication of dental prosthetics, aligners, and surgical guides with greater accuracy and efficiency, is positively influencing the market.

What is included in market segmentation?

The report provides detailed segmentation of the global 3d printing in healthcare market based on based on material, technology, application, end user and region.

Breakup by Material:

- Polymer

- Metals

- Ceramic

- Organic

Breakup by Technology:

- Droplet Deposition

- Fused Filament Fabrication (FFF) Technology

- Low-temperature Deposition Manufacturing (LDM)

- Multiphase Jet Solidification (MJS)

- Photopolymerization

- Stereolithography (SLA)

- Continuous Liquid Interface Production (CLIP)

- Two-photon Polymerization (2PP)

- Laser Beam Melting

- Selective Laser Sintering (SLS)

- Selective Laser Melting (SLM)

- Direct Metal Laser Sintering (DMLS)

- Electronic Beam Melting (EBM)

- Laminated Object Manufacturing

- Others

Breakup by Application:

- External Wearable Devices

- Hearing Aids

- Prosthesis and Orthotics

- Dental Products

- Clinical Study Devices

- Drug Testing

- Anatomical Models

- Implants

- Surgical Guides

- Cranio-maxillofacial Implants

- Orthopedic Implants

- Tissue Engineering

Breakup by End User:

- Medical and Surgical Centers

- Pharmaceutical and Biotechnology Companies

- Academic Institutions

Breakup by Region:

- North America

- United States

- Canada

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

The report provides a comprehensive analysis of the industry key players listed below:

3D Systems Inc., Desktop Metal Inc., EOS GmbH, Formlabs, Materialise NV, Organovo Holding Inc., Oxford Performance Materials Inc., Prodways Tech, Proto Labs Inc., Renishaw plc, SLM Solutions Group AG and Stratasys Ltd.

Comments