Hydraulic presses are the backbone of many industries, offering unmatched strength and precision in a variety of applications. From metal stamping and forging to plastic molding and automotive manufacturing, these powerful machines are designed to deliver high performance, speed, and efficiency. Whether you're in the automotive, aerospace, or metalworking industry, selecting the right hydraulic press can significantly impact productivity and operational efficiency. In this article, we’ll explore the features and benefits of hydraulic presses, as well as guide you on how to discover the best hydraulic press solutions for your business needs.

What is a Hydraulic Press?

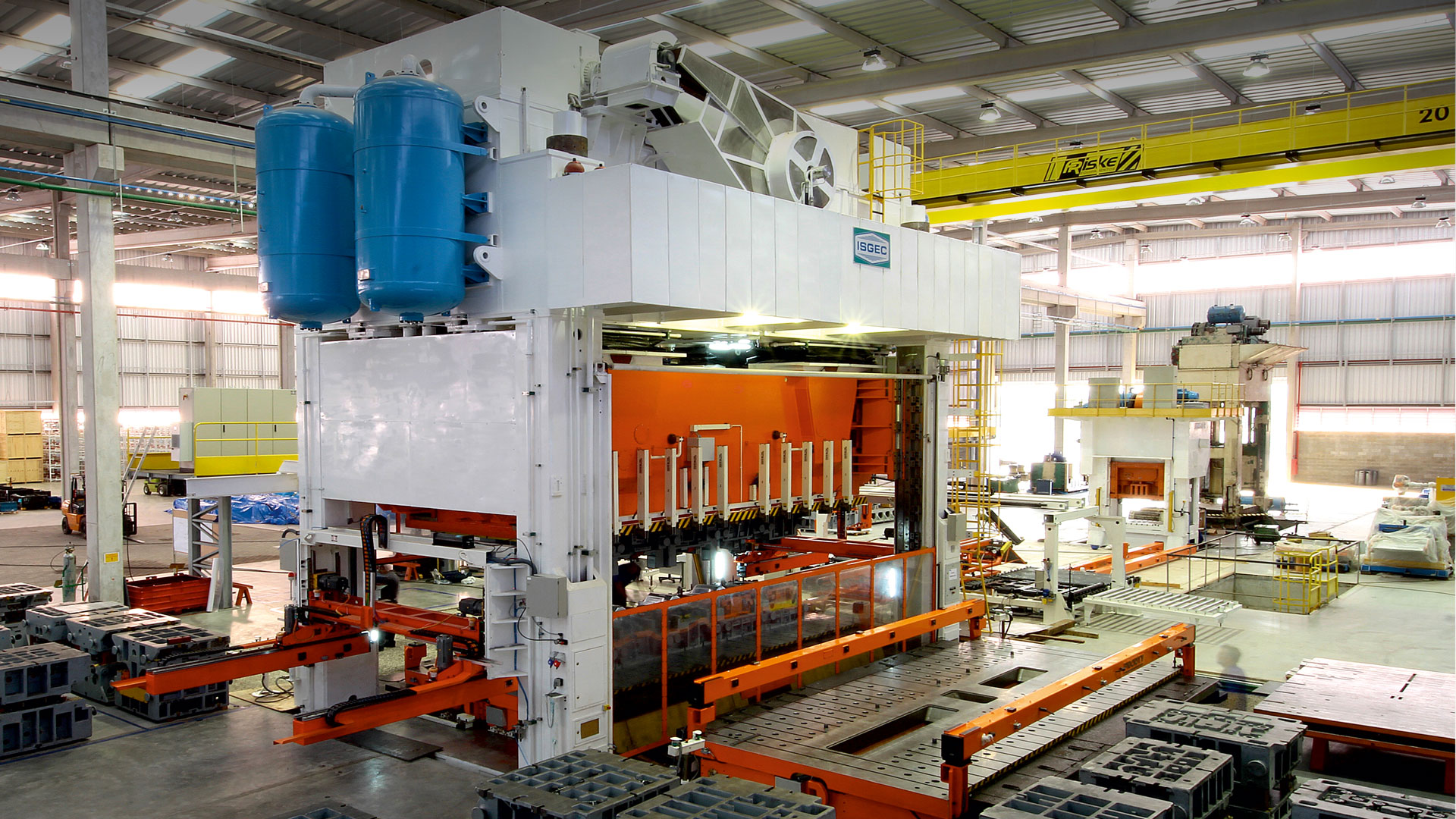

A hydraulic press is a machine that uses hydraulic force to shape, form, or assemble materials. It operates by applying pressure through a fluid-filled piston system to move a ram that exerts force on the workpiece. This system is capable of generating immense pressure, which is why hydraulic presses are used in heavy-duty applications that require significant strength, such as metal forming, plastic molding, and even car manufacturing.

Hydraulic presses come in various sizes and configurations, each designed to meet the specific needs of a business. From small bench presses used in laboratories to large, custom-built machines designed for high-volume manufacturing, the versatility of hydraulic presses makes them an indispensable tool in modern industry.

Key Benefits of Hydraulic Press Solutions

Unmatched Strength and Power

The primary reason hydraulic presses are so widely used is their incredible strength. By utilizing hydraulic force, these presses are capable of applying thousands of tons of pressure, making them ideal for tasks that involve shaping, bending, or forming hard materials like metals and plastics. Whether you’re stamping intricate parts for the automotive industry or forming large sheets of metal, the power of a hydraulic press allows for precision and efficiency.

Precision and Consistency

Hydraulic presses are not only powerful but also incredibly precise. The hydraulic system ensures that force is applied evenly and consistently across the workpiece, which is crucial for industries that require exact measurements and quality control. For instance, in metal stamping, hydraulic presses can achieve consistent part dimensions with minimal variation, resulting in high-quality products that meet the required specifications.

Energy Efficiency

Hydraulic presses are known for their energy efficiency, particularly when compared to mechanical presses. The hydraulic system’s ability to adjust the force dynamically means that less energy is wasted, and energy is applied directly to the task at hand. In industries where large amounts of force are needed over extended periods, the energy efficiency of hydraulic presses can lead to substantial cost savings over time. Additionally, these presses can often be operated at lower speeds without sacrificing performance, reducing energy consumption while still producing high-quality results.

Versatility Across Industries

Hydraulic presses are used across a wide range of industries, and their versatility makes them a staple in modern manufacturing. In the automotive industry, hydraulic presses are used for metal forming, stamping, and assembly of various components. In aerospace, they are employed for forging and forming critical parts that require high strength and precision. Plastic molding and rubber production are also major sectors where hydraulic presses are essential for shaping and forming materials. Their ability to handle a variety of materials and applications ensures that hydraulic presses remain one of the most versatile machines on the market.

Customization for Specific Needs

One of the key advantages of hydraulic press solutions is the ability to customize the machine to fit your exact requirements. Manufacturers offer various configurations, including C-frame presses, H-frame presses, and four-post presses, among others. Additionally, hydraulic presses can be tailored to suit specific needs, such as stroke length, tonnage, and bed size. This level of customization ensures that businesses can get the right solution for their unique operations, improving both productivity and efficiency.

How to Choose the Best Hydraulic Press for Your Needs

When choosing a hydraulic press, several factors should be taken into account to ensure that you get the best solution for your business. Here are some key considerations:

Application Requirements

The first step in selecting a hydraulic press is understanding the specific application it will be used for. Different applications require different forces, stroke lengths, and press configurations. For example, a metal stamping application may require a press with a large tonnage capacity, while plastic molding might need a press with a longer stroke.

Tonnage and Force Requirements

Hydraulic presses are available in a range of tonnages, which determine the amount of force the machine can apply. The right tonnage depends on the materials you are working with and the size of the workpieces. Choosing the appropriate tonnage ensures that your press can handle the demands of your operation without being overpowered or underpowered.

Size and Configuration

The size and configuration of the hydraulic press should also match the space and layout of your facility. Depending on your production floor’s layout, you may need a press with a smaller footprint or one that can be easily integrated into an automated production line.

Automation Capabilities

Many modern hydraulic presses come with advanced automation features, such as robotic arms, material handling systems, and computerized controls. These automation features can significantly enhance the speed and precision of your production processes while reducing labor costs and human error. If your operation involves high-volume production, investing in a press with automation capabilities can boost efficiency and output.

Maintenance and Support

Regular maintenance is crucial to ensuring that your hydraulic press continues to operate at peak performance. When selecting a hydraulic press provider, it’s important to choose one that offers strong customer support and maintenance services. Look for manufacturers who provide training, spare parts, and ongoing technical support to help you keep your press in optimal condition.

Conclusion

Hydraulic presses are a powerful and efficient solution for a wide range of manufacturing processes. With their ability to generate immense force, deliver precise results, and operate efficiently, they are an indispensable tool in industries such as automotive, aerospace, and metalworking. By understanding the key benefits of hydraulic press solutions and considering factors such as application requirements, tonnage, and automation capabilities, businesses can find the best hydraulic press for their needs. Whether you're looking to enhance productivity, improve product quality, or reduce energy consumption, investing in the right hydraulic press solution will pay off in the long run, providing strength, efficiency, and precision for your operations.

.jpg)

Comments