In sectors that require strength, durability, and accuracy, the selection of a suitable Forging Parts Manufacturer plays a key role. When procuring parts for automotive, agricultural, or structural applications, your manufacturer needs to be able to provide uniform quality with cost-effectiveness and technological advancement. With many possibilities out there in the market, it's significant to find a suitable partner who shares your project requirements. This blog describes the key characteristics to seek in a reliable Forging Parts Manufacturer so that you can make an informed choice.

1. Established Experience and Industry Expertise

A reputable Forging Parts Manufacturer should have extensive experience in forging technologies, materials, and component design. Years of experience not only reflect the company’s stability but also indicate their ability to solve complex manufacturing problems. Manufacturers who understand the intricacies of metal deformation, heat treatment, and surface finishing will be more likely to produce parts that meet your specifications. Ask for examples of past projects, client references, and case studies to gauge their capability.

2. Quality Control and Certifications

Quality assurance is an absolute characteristic of any professional Forging Parts Manufacturer. Reputable manufacturers will ensure stringent quality control processes at each step of the production process. Certifications like ISO 9001 or similar reflect that the company complies with global quality management standards. Seek manufacturers that conduct in-house testing using advanced test equipment to ensure consistency and reliability of the forged parts.

3. Design Support and Customization

Most projects involve parts that are custom designed to meet particular uses. A professional Forging Parts Manufacturer will have design in-house capabilities and engineering talent to guide customers through the development process. From prototype creation and CAD modeling to simulation, your manufacturer should be able to assist your product from inception through to final production.

4. Technological Developments

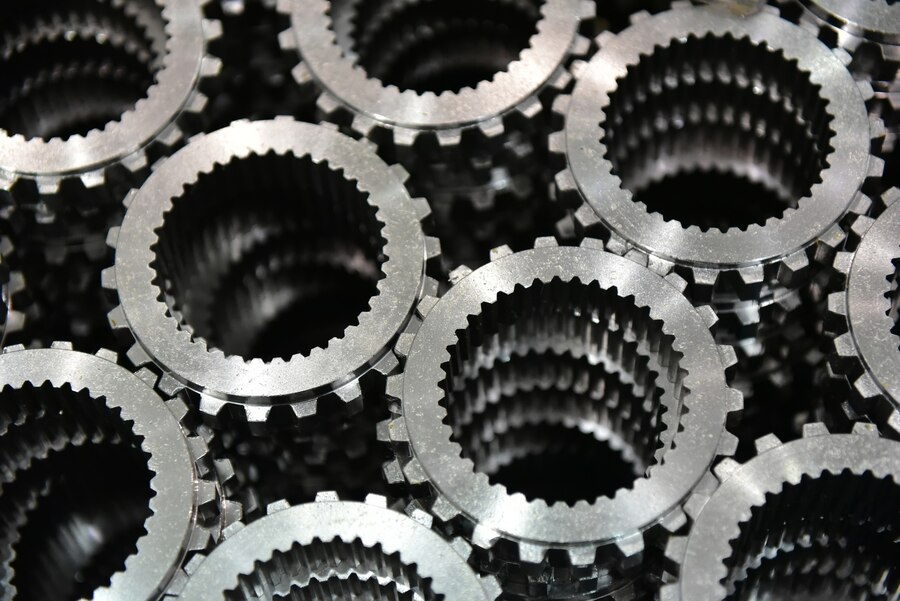

With the current competitive environment, a contemporary Forging Parts Manufacturer should be investing in modern machines and process automation. Sophisticated forging processes such as closed-die forging, hot and cold forging, and computer-aided manufacturing can greatly enhance production efficiency and quality consistency of products. Organizations that keep themselves in line with the newest technology are likely to offer improved tolerances, less material waste, and superior part performance.

5. Material Knowledge

Forging requires handling a vast range of metals, each with different properties and uses. They should assist you in choosing the appropriate metal according to your application, operating conditions, and mechanical needs. Material knowledge has a direct bearing on product longevity, performance, and cost.

6. Production Capacity and Scalability

Whether you require small-batch production or high-volume runs, your selected Forging Parts Manufacturer should have the facilities to scale up or down as required. Verify if the company possesses adequate forging presses, die-making facilities, and machining capacity to process your orders in a timely manner. Lead times, logistics capacity, and on-time delivery records are all measures of a manufacturer's ability to deliver on your timelines.

7. Clear Communication and Customer Support

Communication is important when collaborating with a Forging Parts Manufacturer. Throughout the project, from quoting and prototyping to delivery and post-sales support, your manufacturer must be available and responsive. Having a single point of contact or customer support department can simplify coordination and improve its effectiveness.

8. Competitive Pricing Without Sacrificing Quality

Price is always a factor, but not always the lowest price is the best. An excellent Forging Parts Manufacturer provides competitive prices with high quality standards. Assess their pricing model, terms of payment, and value-added services to ensure long-term affordability. Usually, an additional premium at the initial price pays off in the form of improved durability, lower maintenance, and less replacement over time.

9. Environmental Responsibility

Sustainability is turning out to be a significant element in manufacturing. Top Forging Parts Manufacturer companies follow green-friendly practices like material recycling, energy-efficient working, and waste reduction. Collaborating with a company that is environmentally responsible not only contributes to the health of the planet but can also come in line with your company's CSR objectives and compliance requirements.

G.M. Hi-Tech: A Name You Can Trust in Forging Solutions

One of the excellent Forging Parts Manufacturers fulfilling all the above requirements is G.M. Hi-Tech. Boasting decades of experience in the industry, backed by an enviable reputation, G.M. Hi-Tech provides precision forging components as per varied industrial applications. With the latest technology setup in its advanced facility comprising advanced forging presses and CNC machining centers, the company is capable of ensuring the best quality for every product range. Apart from technical competence, G.M. Hi-Tech has earned reputations for very high levels of customer service, honest communication, and punctuality. With adherence to quality, innovation, and sustainability, it stands as an excellent Forging Parts Manufacturer that caters to customers who seek high-quality, efficient, and effective solutions.

Final Thoughts

Selecting an appropriate Forging Parts Manufacturer is an important consideration for the success of your venture. A good manufacturer doesn't merely make metal parts—they are a strategic ally who assists you in achieving strength, efficiency, and cost-effectiveness. Through considerations of characteristics such as experience, technology savvy, material sophistication, and customer service, you can select with confidence a Forging Parts Manufacturer that brings meaningful value to your organization.

Whether you're looking to source custom parts or scale up production, remember that not all manufacturers are created equal. Prioritize those who demonstrate a commitment to innovation, quality, and client satisfaction—like G.M. Hi-Tech—and you'll be well on your way to building long-lasting, high-performance solutions.

Comments