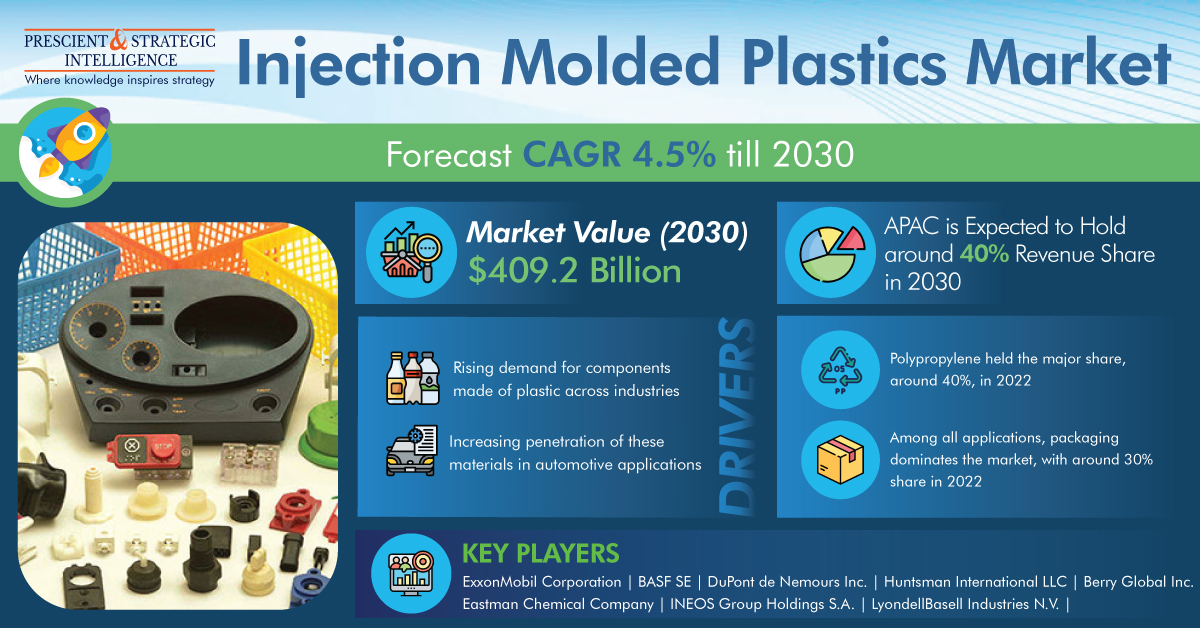

The total value of the global injection molded plastics market was USD 288.9 billion in 2022, and it will rise at a growth rate of above 4.5% shortly, reaching USD 409.2 billion by 2030, according to P&S Intelligence.

This growth can be credited to the increasing demand for machinery manufactures of plastic across industries, like home appliances, automotive, packaging, and medical devices. The increasing demand for medicinal components boosts the consumption of medicinal-grade items, to fulfill medicinal hygiene and well-being standards.

Moreover, the growing usage of such materials in automotive applications, along with the growing infrastructure expenditure, mainly in APAC and Latin America, is projected to remain a main boosting reason for the demand for such materials in the coming few years.

In 2022, Polypropylene had the largest share, of approximately 40%, credited to its lightweight moisture resistance, nature, moisture resistance, shock resistance, high molding capacity, low cost, and brilliant compatibility with food applications, especially in terms of wrapping safety.

It is one of the lowermost-density plastics, and thus is harmless for food containers, as it does not leak chemicals into food items. Furthermore, it can be injection-molded to make parts and items of numerous forms and proportions. Polypropylene also has a semi-crystalline structure, due to which it owns a high flexural forte.

In 2022, among all applications, packaging led the industry, with approximately 30% share thus, the boom of the packing industry is a main boosting reason for the industry. The growing demand for plastic closures and caps is driven by the lasting shift in the customer packaging sector from glass and metals to polymers, due to the latter’s less space necessity (which makes the most of storage space), durability, lower weight, cost-effectiveness, and versatility.

APAC is dominating the injecting molding plastics market, and the region is projected to be dominant throughout the forecast period, with approximately 40% revenue share. The growing infrastructure expenditure, armed with the rising automobile sales in India, China, Malaysia, and Indonesia, is projected to boost injection-molded plastics demand in the APAC region.

The automotive sector is one of the fastest-rising end users of injection-molded plastics. In the coming few years, the development of the Asian automotive sector, mainly in India and China, will boost the demand for such materials.

With the technological novelties in the manufacturing of automobile machinery, thermoplastic resin elastomers, along with other injection-molded polymers, are discovering new applications in the automobile sector. Up till now, the majority of vehicle parts were completed from steel. But, now, steel is being swiftly substituted by plastics, to decrease the total weight of vehicles.

Comments