Speed, precision, and flexibility are critical in today’s product development cycle. That’s why more businesses are investing in quickturn prototyping plastic parts to reduce development time and bring products to market faster without compromising quality.

This guide explores how rapid plastic prototyping works, its advantages, applications, materials, and what to consider when choosing a prototyping service for plastic components.

What Is Quickturn Prototyping?

Quickturn prototyping is the process of rapidly manufacturing plastic parts using specialized tooling and fast-processing techniques. It typically refers to turnaround times measured in days—not weeks—and is ideal for early-stage testing, fit-checking, and functional evaluation.

Unlike full-scale production, which requires long lead times and costly steel molds, quickturn prototyping uses soft tooling, 3D printing, or CNC machining to create plastic parts in a fraction of the time.

Why Quickturn Prototyping Is a Game-Changer

Product development is no longer a linear process. Quick iterations and market responsiveness are essential to maintain competitive advantage. Quickturn plastic prototyping supports this shift with several key benefits:

Faster Product Validation

Engineers and designers can test the look, feel, and function of a component early, reducing the risk of design flaws in mass production.

Lower Development Costs

Quick prototyping avoids expensive production tooling and high-volume material costs, making it ideal for startups or product concept teams.

Streamlined Feedback Loops

Rapid part delivery enables real-time collaboration across design, engineering, and marketing teams for faster iterations and improvements.

Early-to-Market Advantage

With compressed timelines, businesses can introduce new features and innovations ahead of competitors, gaining market traction sooner.

Common Applications of Quickturn Plastic Parts

Consumer Product Development

Quick prototypes help test user ergonomics, packaging, or performance before investing in large-scale production.

Automotive and Aerospace Engineering

High-precision parts such as brackets, housings, and clips are tested for fit and tolerance under real-world conditions.

Medical Device Prototyping

Medical teams use rapid prototypes to evaluate device usability, biocompatibility, and safety compliance before regulatory approvals.

Robotics and Electronics

Custom enclosures, mounts, and fixtures are prototyped quickly to support integration with sensors, wiring, and moving parts.

Core Methods Used in Quickturn Plastic Prototyping

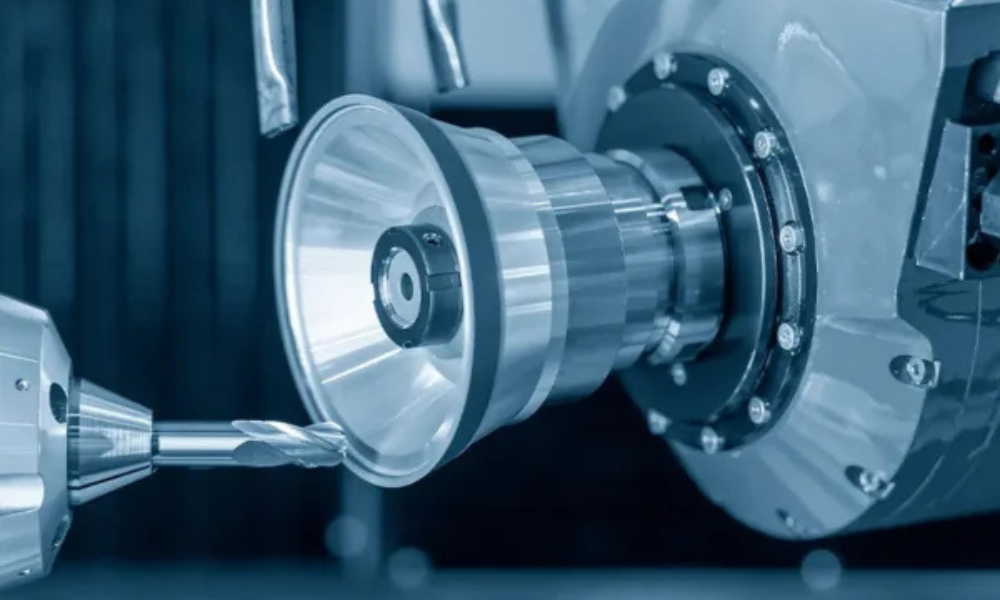

1. CNC Machining

CNC (Computer Numerical Control) removes material from a plastic block to create accurate parts quickly. It’s ideal for functional testing and parts requiring tight tolerances.

Pros: Fast, precise, material flexibility

Cons: Higher cost for complex geometries

2. 3D Printing (Additive Manufacturing)

Technologies like FDM, SLA, and SLS print parts layer by layer, making them perfect for visual models, concept testing, or intricate geometries.

Pros: Complex shapes, fast turnarounds

Cons: May lack strength or finish of molded parts

3. Urethane Casting

This involves creating a silicone mold from a 3D printed or machined master, then casting parts with urethane resin. It’s suitable for low-volume testing of final-product-like materials.

Pros: Good surface finish, flexible material options

Cons: Limited mold life, not suited for high-volume runs

4. Rapid Injection Molding

Soft aluminum tooling is used to produce high-quality injection-molded plastic parts in days. It’s ideal for bridge production or testing real-world performance.

Pros: Production-grade parts, excellent finish

Cons: Higher initial tooling cost than 3D printing

Types of Plastic Materials for Quickturn Prototypes

Material selection impacts durability, flexibility, and test validity. Common plastics used in prototyping include:

ABS (Acrylonitrile Butadiene Styrene)

Durable, impact-resistant, and widely used for housings and mechanical parts.

Polycarbonate (PC)

Strong and transparent, suitable for lenses, shields, and enclosures requiring toughness.

Nylon (PA)

Lightweight with good chemical resistance, ideal for mechanical and automotive components.

PEEK (Polyetheretherketone)

High-performance plastic for medical and aerospace testing under extreme conditions.

TPE/TPU (Thermoplastic Elastomers)

Used when prototypes require flexibility, softness, or rubber-like characteristics.

Choosing the right plastic depends on end-use application, mechanical performance, and testing goals.

Design Guidelines for Quickturn Prototyping Plastic Parts

Efficient prototyping isn’t just about speed—it’s about building right the first time. Keep these design best practices in mind:

Maintain Uniform Wall Thickness

Inconsistent walls can cause warping or weak spots. Aim for uniformity to ensure strength and even material flow.

Add Fillets and Radii

Sharp corners are stress concentrators. Use fillets to reduce cracking and improve moldability.

Consider Undercuts and Draft Angles

Minimize undercuts to simplify tooling. Apply draft angles to allow easy release from molds.

Optimize for Material Shrinkage

Different plastics shrink at different rates. Account for this in your CAD design to avoid tolerance issues.

Turnaround Time Expectations

The whole point of quickturn prototyping is speed. Here’s a general breakdown of timelines depending on the method:

MethodTypical Turnaround Time3D Printing1–3 business daysCNC Machining2–5 business daysUrethane Casting7–10 business daysRapid Injection Molding7–15 business days

Timelines may vary depending on part complexity, quantity, and material availability.

How to Choose a Quickturn Prototyping Partner

Not all prototyping services deliver the same level of quality and speed. When selecting a provider, assess them based on:

- In-house capabilities – Do they offer multiple methods like 3D printing, machining, and molding?

- Material options – Can they source and work with your target production-grade plastics?

- Engineering support – Are they able to assist in DFM (Design for Manufacturability)?

- Speed and scalability – Can they handle urgent requests and transition to production if needed?

- Quality standards – Do they follow ISO or industry-compliant procedures for inspection and verification?

A strong prototyping partner isn’t just a vendor—they’re a development ally.

Common Mistakes to Avoid in Plastic Prototyping

Overengineering the Design

Prototype only what's necessary. Extra complexity increases cost and time without improving feedback.

Ignoring End-Use Requirements

Choose materials and methods that closely simulate the final use conditions. A prototype is only useful if it’s realistic.

Not Planning for Production

If the prototype succeeds, you’ll need to scale. Make sure designs are compatible with mass production processes like injection molding.

Future Trends in Plastic Part Prototyping

AI-Driven Design Automation

AI tools will streamline CAD modeling and automatically optimize designs for prototyping, reducing development cycles.

Sustainable Prototyping Materials

Biodegradable and recycled plastics are being tested in 3D printing and low-volume molding to reduce environmental impact.

Hybrid Manufacturing

Combining additive and subtractive methods allows faster iterations and higher customization within the same workflow.

Digital Twin Integration

Virtual simulations paired with physical prototypes enable more precise testing, failure prediction, and lifecycle analysis.

Final Thoughts

Quickturn prototyping plastic parts isn’t just a production shortcut—it’s a strategic tool for smarter design, faster validation, and leaner product development. Whether you’re refining a concept or testing fit before production, rapid prototyping allows you to fail faster, learn quicker, and build better.

By selecting the right process, materials, and partners, you can reduce risks, lower costs, and accelerate your time to market with confidence.

Comments