The additive manufacturing market is continuously evolving, driven by technological advancements, shifting industry demands, and emerging trends. Here are some of the latest trends and industry statistics shaping the landscape:

Latest Trends:

- Metal Additive Manufacturing: There's a growing focus on metal additive manufacturing market driven by advancements in metal 3D printing technologies, materials, and processes. This trend is particularly notable in aerospace, automotive, and healthcare industries, where high-performance metal parts are in demand.

- Multi-Material 3D Printing: Manufacturers are exploring multi-material 3D printing capabilities, enabling the production of complex, functional parts with diverse material properties in a single print run. This trend enhances design flexibility and opens up new possibilities for applications across industries.

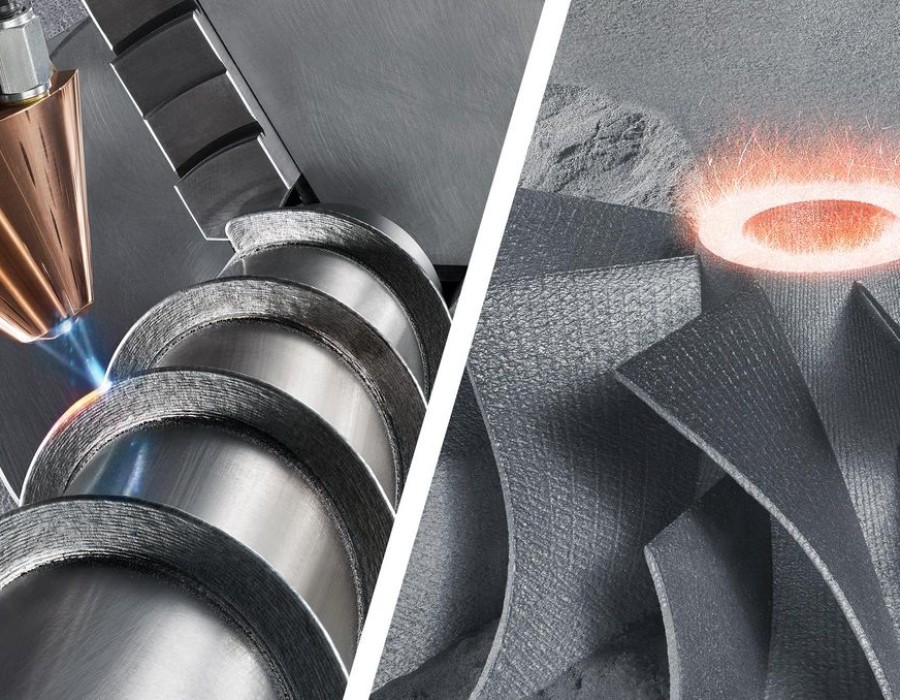

- Hybrid Manufacturing: Hybrid manufacturing, combining additive and subtractive processes in a single machine, is gaining traction for producing high-precision components with improved surface finishes. This approach offers the benefits of both additive and subtractive manufacturing technologies.

- Industry 4.0 Integration: Additive manufacturing is increasingly integrated into Industry 4.0 initiatives, leveraging data analytics, IoT, AI, and automation to optimize production processes, monitor machine performance, and enable predictive maintenance.

- Mass Customization: The demand for mass customization is driving the adoption of additive manufacturing in various industries, allowing companies to produce personalized products and components cost-effectively and at scale. This trend is particularly prominent in healthcare, consumer goods, and automotive sectors.

- Sustainability Initiatives: Additive manufacturing is being embraced for its sustainability benefits, including reduced material waste, energy efficiency, and on-demand production. Manufacturers are leveraging 3D printing to support circular economy principles and reduce environmental impact.

- Digital Supply Chains: Additive manufacturing facilitates digital supply chains by enabling decentralized production, on-demand manufacturing, and virtual inventory management. This trend reduces lead times, inventory costs, and supply chain vulnerabilities, particularly in light of disruptions like the COVID-19 pandemic.

Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2023-2032 – By Product Type, Application, End-user, and Region: (North America, Europe, Asia Pacific, Latin America and Middle East and Africa): https://www.persistencemarketresearch.com/market-research/additive-manufacturing-market.asp

Industry Statistics:

- Market Size: The global additive manufacturing market size is projected to reach tens of billions of dollars by the mid-2020s, with steady growth expected over the forecast period.

- Revenue Growth: Revenue generated from additive manufacturing solutions, including 3D printers, materials, software, and services, continues to grow, driven by increasing adoption across industries and technological advancements.

- Adoption Rates: Adoption of additive manufacturing technology varies across industries, with sectors like aerospace, automotive, healthcare, and consumer goods leading in implementation. However, adoption is also increasing in areas such as construction, electronics, and energy.

- Investment Trends: Investment in additive manufacturing technology remains strong, with companies, governments, and research institutions investing in R&D, infrastructure, and workforce development to support innovation and market expansion.

- Regional Dynamics: North America, Europe, and Asia-Pacific are key regions driving growth in the additive manufacturing market, with each region experiencing varying rates of adoption, regulatory frameworks, and industry focus areas.

These latest trends and industry statistics underscore the dynamic nature of the additive manufacturing market and the transformative impact of 3D printing technology across sectors and geographies.

Companies Covered in This Report -

· Renishaw Plc

· Materialise

· Wipro Limited

· ANSYS, Inc.

· Siemens Industry Software Inc.

· Evonik

· Stratasys Ltd.

· Xerox Corporation

· General Electric

· AMFG

· Optomec

· American Additive Manufacturing LLC

· Mazak Corporation.

About Persistence Market Research:

Business intelligence is the foundation of every business model employed by Persistence Market Research. Multi-dimensional sources are being put to work, which include big data, customer experience analytics, and real-time data collection. Thus, working on “micros” by Persistence Market Research helps companies overcome their “macro” business challenges.

Persistence Market Research is always way ahead of its time. In other words, it tables market solutions by stepping into the companies’/clients’ shoes much before they themselves have a sneak pick into the market. The pro-active approach followed by experts at Persistence Market Research helps companies/clients lay their hands on techno-commercial insights beforehand, so that the subsequent course of action could be simplified on their part.

Contact

Persistence Market Research

Teerth Techno space, Unit B-704

Survey Number - 103, Baner

Mumbai Bangalore Highway

Pune 411045 India

Email: [email protected]

Web: https://www.persistencemarketresearch.com

Comments