Introduction

Connector insertion automation is quickly becoming a foundation of present-day manufacturing. Via automating this pivotal step, makers are reaping benefits like increased efficiency, accuracy, and cost-adequacy. This article investigates the key advantages of connector insertion automation and its effect on manufacturing processes.

Outline

Introduction

Significance of Connector Insertion in Manufacturing

Advantages of Automation in Connector Insertion

Increased Efficiency

Upgraded Accuracy and Quality

Cost Decrease

Further developed Security

Adaptability and Adaptability

Implementing Automation in Manufacturing

Conclusion

FAQs

Background: Significance of Connector Insertion in Manufacturing

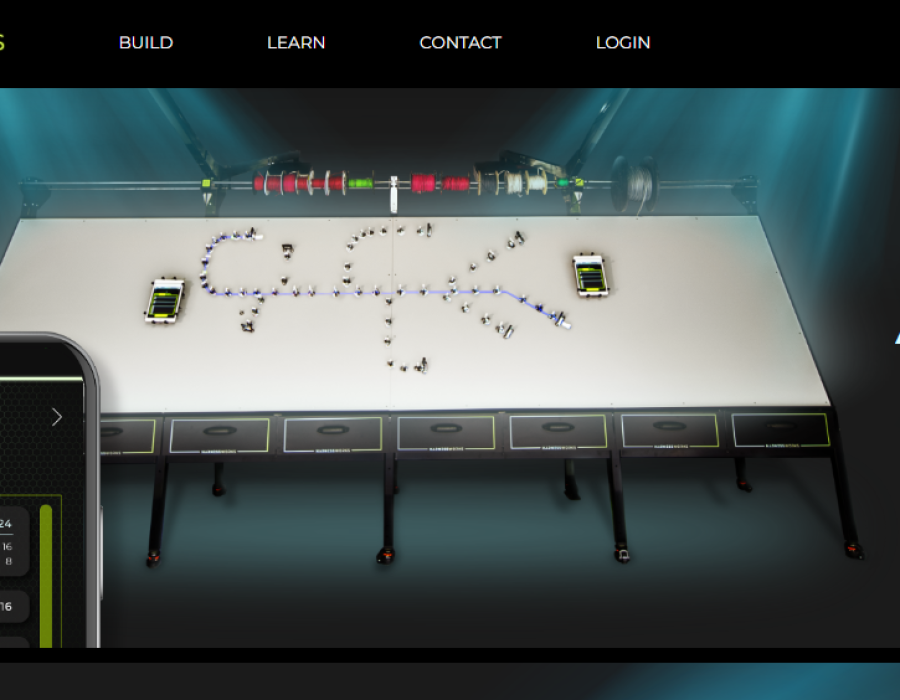

Connector insertion is an essential cycle in industries like auto, hardware, and aviation. It involves placing connectors onto wires, links, or circuit sheets to lay out dependable electrical associations. Customarily, this interaction was manual, requiring talented specialists to guarantee precision. Nonetheless, manual insertion is work-intensive, inclined to human blunder, and tedious, making automation an appealing arrangement.

Advantages of Automation in Connector Insertion

Increased Efficiency

Automating connector insertion fundamentally supports creation speed. Machines can work continuously without exhaustion, handling dull assignments quicker than human laborers. This prompts more limited creation cycles and higher results, allowing makers to satisfy growing needs all the more successfully.

Improved Accuracy and Quality

Automation guarantees reliable accuracy in connector situations, reducing the probability of deformities brought about by human mistake. This elevated degree of precision is fundamental in industries where even minor errors can prompt item disappointment or security issues. With computerized frameworks, producers can maintain severe quality control standards.

Cost Decrease

While the initial investment in automation innovation might be significant, the drawn-out cost savings are extensive. Automation lessens work costs, minimizes material waste because of fewer deformities, and brings down the costs related to modification and quality control. Over the long haul, these savings can altogether offset the forthright expenses.

Further developed Security

Automation diminishes the requirement for human laborers to perform monotonous, truly demanding, or dangerous assignments, thereby lowering the risk of work environment injuries. Laborers can zero in on more perplexing, value-added exercises, improving by and large work fulfillment and security.

Versatility and Adaptability

Computerized frameworks can be effectively scaled to oblige increased creation volumes or adjusted to handle various sorts of connectors. This adaptability permits manufacturers to respond rapidly to changes in market demand or item determinations without the requirement for huge retooling or retraining.

Implementing Automation in Manufacturing

To effectively execute connector insertion automation, makers ought to begin with an intensive evaluation of their creation needs. This includes evaluating current cycles, identifying bottlenecks, and determining the particular prerequisites for automation. Choosing the right hardware and ensuring legitimate integration with existing frameworks is significant. Furthermore, providing training for representatives and maintaining ongoing help will assist with maximizing the benefits of automation.

Conclusion

Connector insertion automation offers various advantages for makers, including increased efficiency, accuracy, cost savings, wellbeing, and versatility. As the manufacturing landscape continues to develop, adopting automation will be key to staying serious and meeting the demands of present-day creation.

FAQs

What industries benefit the most from connector insertion automation?

Industries, for example, cars, gadgets, and aviation benefit essentially because of the appeal for accuracy and unwavering quality.

Is automation reasonable for limited-scope manufacturing?

Indeed, automation can be scaled to fit limited scope tasks, offering benefits, for example, further developed efficiency and consistency even at lower creation volumes.

What are the main challenges in implementing connector insertion automation?

The main challenges include the initial investment cost, integration with existing frameworks, and the requirement for worker training.

Could computerized frameworks handle various sorts of connectors?

Indeed, present-day computerized frameworks are intended to be adaptable and can be adjusted to handle different connector types and sizes.

How does automation influence item quality?

Automation upgrades item quality by ensuring predictable accuracy in connector position, reducing the probability of deformities, and improving by and large dependability.

Comments