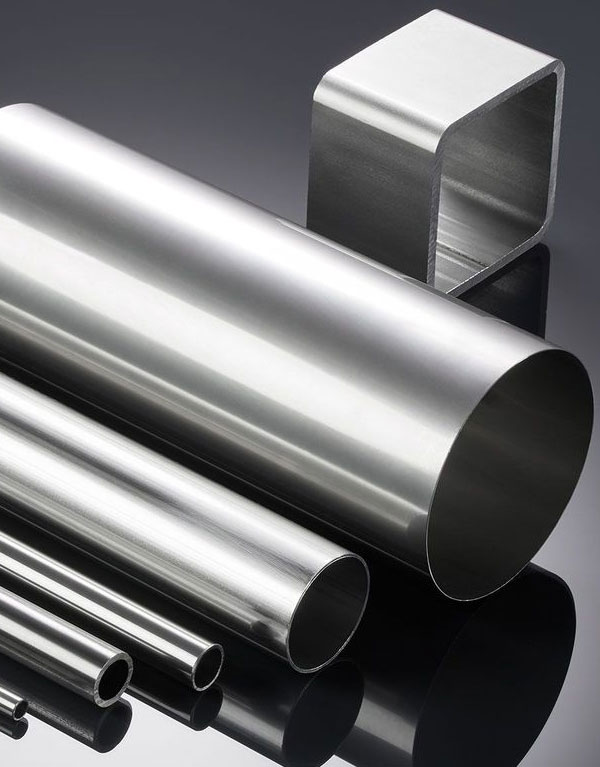

Stainless steel has been the go-to material for creating new industrial items for decades. Since it contains chromium, it is highly resistant to corrosion. When exposed to chloride liquids, it resists erosion and pitting exceptionally well. Stainless steel is superior to other metals for pipe manufacturing due to its high strength, long service life, and low maintenance requirements. A combination of nickel, chromium and iron in its chemical makeup gives stainless steel many valuable properties.

There are various kinds of stainless steel pipes.

- Stainless Steel 316L Pipe

Stainless Steel 316L Pipe manufacturers in India made an austenitic stainless steel with lower carbon content than the 316 grade. Its main elements are chromium, nickel, and molybdenum. The pipes are less difficult to weld because of their low carbon content.

- Stainless Steel 310 Pipe

Stainless Steel 310 Pipe is a chromium-nickel alloy, making it as strong as 304-grade pipes while offering improved resistance to corrosion and oxidation. Stainless Steel 310 Pipe suppliers in India provides items of several sizes and styles are available from Steel, a top provider and manufacturer in this industry.

- Hastelloy C276 Round Bar

Incorporating nickel, molybdenum, and chromium into the alloy, Hastelloy C276 is endowed with remarkable strength and durability. The corrosion resistance of the Hastelloy C276 Round Bar is well-known. Hastelloy C276 Round Bar, like the other nickel-based alloy, offers excellent formability, ductility, and weld ability. It is also known for being resistant to stress corrosion cracking in chloride conditions.

- HR Coil

Steel coils of the highest quality, by HR Coil suppliers in India, find widespread use in manufacturing. To create hot rolled coils, steel is moved at a temperature higher than its average recrystallization temperature. Hot-rolled steel coils are more malleable than cold-rolled sheets because they can be heated to higher temperatures and bent and twisted into unique shapes. A hot rolled steel coil will have a scaly grey appearance and softened less sharp corners. They find everyday use in manufacturing and metallurgy, where precise measurements aren’t as crucial.

- IS 1239 Pipe

Besides water, the carbon-based IS 1239 Pipe is also proposed to transport non-hazardous gases, air, and steam. According to the specifications of this standard, the nominal bore size of IS 1239 Carbon Steel Pipe can range from 6 mm to 150 mm.

- Duplex Pipe

Duplex pipes are stainless pipes with very high chromium and shallow nickel content. Pipes by Duplex Pipe suppliers in India are highly durable and resistant to corrosion. Desalination facilities, heat exchangers, and marine operations use duplex pipes.

- Super Duplex Pipe

Super Duplex Pipe suppliers in India offers fittings, made of a unique form of stainless steel, are frequently employed in high-pressure or high-temperature environments. This flange, also called a duplex flange, is a pipe fitting built of duplex stainless steel with a melting temperature of 2000 degrees Celsius.

Conclusion

There is a significant reliance on these pipes in the oil and gas industry due to their durability and resilience under extreme conditions. These pipes are also utilized in nuclear power plant reactors and pumps. Seawater applications, heat exchangers, power generation, the petrochemical and pharmaceutical industry, and many other industries also use stainless steel pipes.

Comments