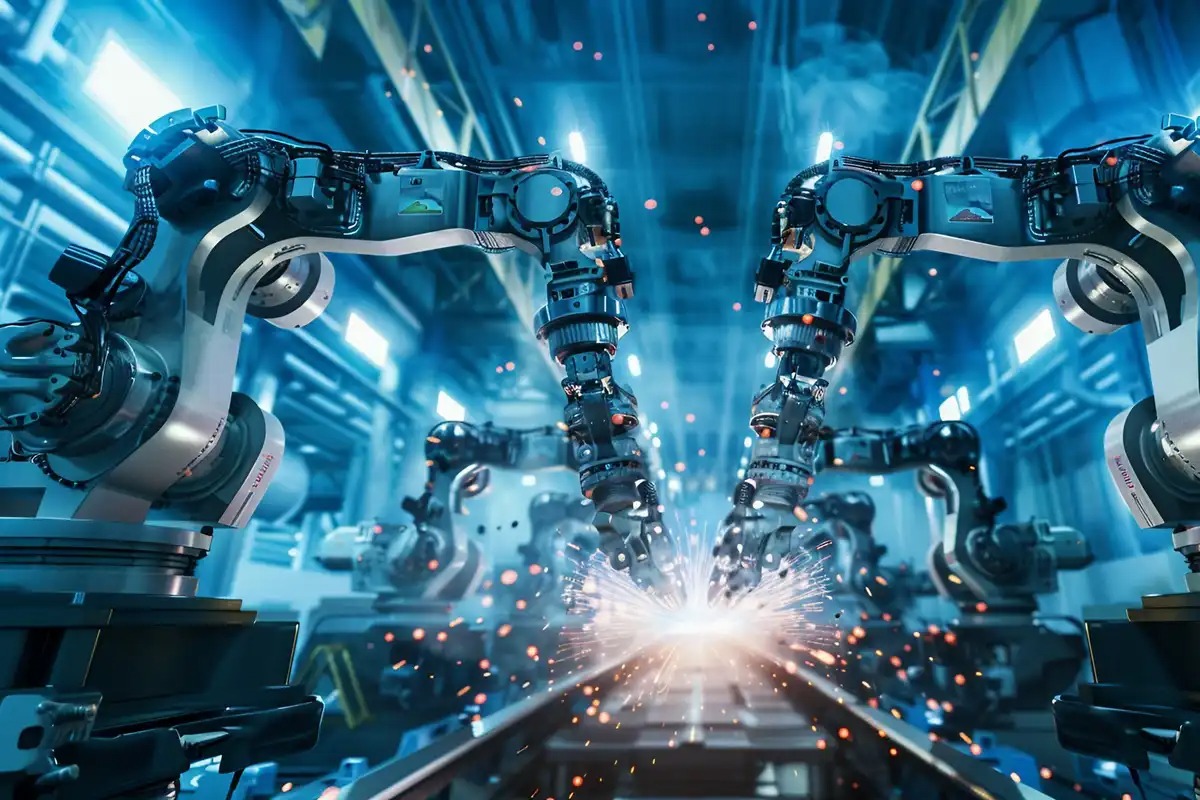

When purchasing welding equipment, it is very important to help make well informed judgements to guarantee you find the right tools to meet your needs. Listed here are seven key things to consider to be aware of: Get more information about plasma cutting

1. Comprehend Your Welding Needs

Before buying any welding equipment, evidently define your particular welding requirements. Are you working on automotive projects, heavy industrial tasks, or simple home repairs? Different types of welding machines cater to various demands, so knowing your primary use will help you pick the best option equipment.

2. Forms of Welding Machines

There are several forms of welding machines, every designed for specific reasons:

MIG Welders: Best for beginners, they may be user-friendly and excellent for welding thicker metals.

TIG Welders: Perfect for specific and clean welds, often used in automotive and artistic applications.

Stay Welders: Long lasting and versatile, ideal for outdoor and heavier materials.

Flux-Cored Welders: Similar to MIG welders but far better for outdoor use and heavier materials.

3. Power Needs

Look at the power provider obtainable in your work space. Welding machines typically call for either 110/120V or 220/240V. Be sure that your power source can support the machine you mean to buy. Some welders offer you two voltage abilities, providing far more versatility.

4. Portability and Space

Assess the space offered in your work shop and the demand for portability. If you frequently shift between job sites, a light-weight and portable welding machine are often more hassle-free. On the other hand, should your welding tasks are fixed, a larger, more powerful machine might be ideal.

5. Obligation Period

The job period signifies the level of time a welding machine can run continuously prior to having to cool down. A better obligation pattern is important for extended, continuous welding sessions, specifically in expert or industrial adjustments. Check the job pattern specifications of your machine to match your work load.

6. Budget

Figure out your budget prior to shopping for welding equipment. Whilst it’s luring to choose the cheapest option, investing inside a high-quality machine can help to save money in the long work by reduction of maintenance fees and improving productivity. Balance your budget with the functions and stability you will need.

7. Safety Characteristics

Safety is key in welding. Look for machines equipped with crucial safety functions including thermal excess protection, which inhibits overheating, and voltage variation safety measures. In addition, make sure you have proper personal protective equipment (PPE) like welding helmets, hand protection, and aprons.

FAQs

1. Which kind of welder is best for beginners?

MIG welders are generally considered the best option for beginners because of the ease of use and versatility. They are great for many different projects, including automotive repairs and metal fabrication.

2. Should I make use of a 220V welder over a 110V electric outlet?

No, a 220V welder requires a 220V power supply. However, some welders have double voltage functionality, permitting them to work on both 110V and 220V retailers.

3. What exactly is a responsibility pattern in welding?

The job pattern may be the amount of time a welding machine can work in a 10-moment period well before it has to cool off. For example, a 60Percent responsibility period means the machine can weld for 6 a few minutes after which must cool for 4 minutes.

4. Are there any welding machines suitable for outdoor use?

Sure, flux-cored welders and put welders are particularly well-suited for outdoor use because of their power to handle windy conditions and weld heavier materials effectively.

5. Why is safety equipment crucial in welding?

Welding entails high temperature ranges, brilliant light, and unsafe toxic gases, which may be harmful. Safety equipment like welding headwear, gloves, and aprons protect you from burns, eye damage, and inhalation of poisonous toxic gases.

6. How do I select the right welding machine for my project?

Identify the primary utilization of the welding machine, the sort of materials you'll be working with, your power provide, plus your budget. Thinking about these elements will help you select a machine that fits your particular needs.

7. What are the common safety capabilities in welding machines?

Common safety features consist of energy excess protection, which helps prevent the machine from overheating, and voltage change safety measures that protect the machine from power surges.

By thinking of these key aspects and handling common queries, you can produce a a lot more informed decision when buying welding equipment, ensuring that you pick the right tools for the distinct welding demands.

Comments