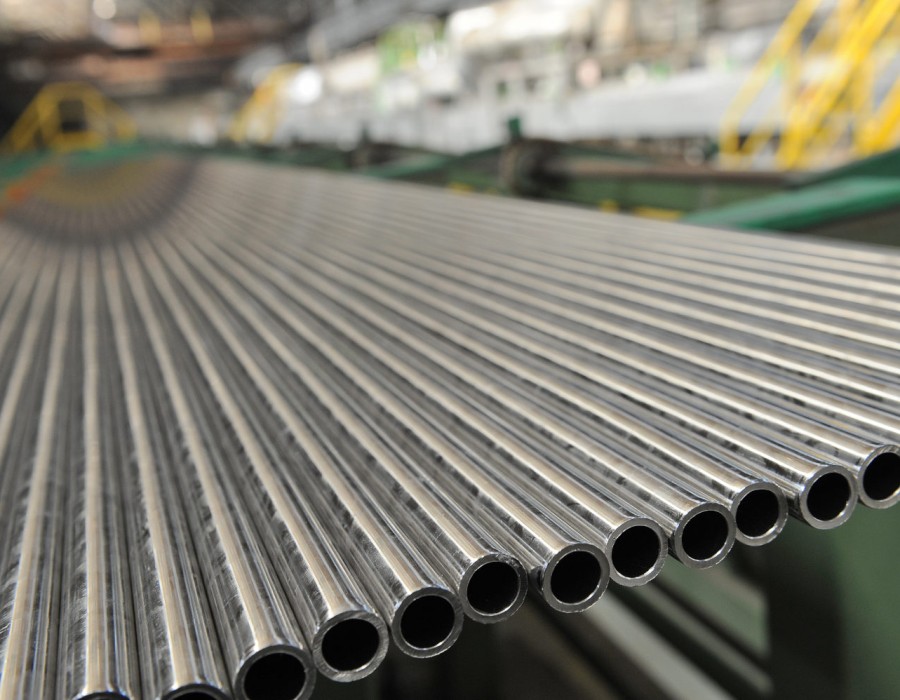

The integrity of products is of prime importance in any industry. Manufacturers must ensure their products remain in perfect condition throughout transportation and storage. The metal industry is no different, where metals like nickel, iron, and chromium require protection against corrosion. Incoloy 800 tubes are the perfect solution for storing and transporting metals in harsh environments. In this blog post, we will discuss the importance of safeguarding product integrity and the role of Incoloy 800 tubes in metal transport and storage.

Corrosion Resistance: Metals used in manufacturing industries are prone to rust and corrosion when exposed to harsh environments. Incoloy 800 tubes offer excellent resistance to corrosive and acidic conditions, making them ideal for transporting and storing metals. The tubes have a tough oxide layer that prevents rust or corrosion to the internal structure, ensuring the product remains in perfect condition.

Strength and Durability: Incoloy 800 tubes are incredibly robust and durable, capable of withstanding high pressure. They can easily sustain exposure to temperatures up to 1600°F for an extended period, which enables them to hold even the most massive and robust materials without buckling under pressure. The tubes are also resistant to cracking or breaking, which makes them an excellent choice for harsh industrial environments.

Easy Maintenance: Incoloy 800 tubes require minimal maintenance despite their heavy-duty use in industrial settings. These tubes are easy to clean and maintain, ensuring long-lasting functionality and operational efficiency. The tubes' smooth internal surface makes them easy to clean regularly, protecting the materials inside from contamination or dust.

Cost-Effective: Incoloy 800 tubes are an affordable solution for safeguarding product integrity in the metal industry. The tubes' robust build and corrosion-resistant properties guarantee long-term functionality at a low cost. Their durability is a significant advantage, saving manufacturers from frequent replacement costs and making them the go-to choice for industrial-scale operations.

Versatility: Incoloy 800 tubes are versatile and readily available in various forms, including welded, seamless, and U-bend configurations. These tubes are customizable to specific lengths, making them perfect for various industrial applications. This versatility ensures that these tubes are fit for any industrial use that requires safe and effective transport and storage of materials.

What are the main uses of Incoloy 800 Tubes?

Incoloy 800, a nickel-iron-chromium alloy, is known for its excellent resistance to oxidation, corrosion, and high-temperature strength. Due to these unique properties, Incoloy 800 tubes find various applications across different industries. Here are the main uses of Incoloy 800 tubes:

Heat Exchangers and Heat Processing Equipment:

Incoloy 800 tubes are commonly used in heat exchangers and processing equipment due to their ability to withstand high temperatures and maintain excellent corrosion resistance.

Furnace Components and Industrial Furnaces:

Incoloy 800 tubes are employed in constructing furnace components, such as radiant tubes and muffle furnaces, where they endure extreme temperatures and thermal cycling.

Chemical Processing and Petrochemical Industry:

Incoloy 800 tubes are utilized in various chemical processing applications, including reactors, piping systems, and equipment for handling corrosive chemicals, acids, and alkaline solutions.

Power Generation Industry:

Due to their resistance to oxidation and thermal stress, Incoloy 800 tubes find applications in power plants, especially in components like boilers, superheater tubes, and reheater tubes.

Aerospace and Aircraft Industry:

Incoloy 800 tubes are used in aircraft engine components, such as afterburner liners and exhaust manifolds, where they endure high temperatures and maintain their mechanical properties.

Nuclear Power Industry:

Due to their corrosion resistance and high-temperature strength, Incoloy 800 tubes are employed in nuclear power plants for components like steam generator tubing, reactor core applications, and nuclear fuel reprocessing equipment.

Food Processing Industry:

Incoloy 800 tubes are used in heat exchangers and other equipment in the food processing industry that requires resistance to high-temperature steam and corrosive food products.

Pulp and Paper Industry:

Incoloy 800 tubes are utilized in various equipment within the pulp and paper industry, including digesters, liquor heaters, and bleach towers, due to their ability to withstand the harsh chemicals and high temperatures involved in paper production.

Oil and Gas Industry:

Incoloy 800 tubes are used in oil refineries, gas processing plants, and petrochemical facilities for heat exchangers, condenser tubes, and high-temperature piping systems.

Waste Treatment and Environmental Applications:

Incoloy 800 tubes are employed in equipment used for waste treatment processes, where they resist corrosion from aggressive chemicals and high-temperature conditions.

Overall, the versatility and resistance to high-temperature and corrosive environments make Incoloy 800 tubes valuable in various industrial applications.

Conclusion:

Incoloy 800 tubes are a cost-effective, durable, and versatile solution to safeguarding product integrity in the metal industry. These tubes offer excellent resistance to rust and corrosion, making them ideal for harsh industrial work environments. They are also easily maintained, customizable, and capable of withstanding high pressures. Overall, Incoloy 800 tubes are the perfect option for manufacturers looking for a long-lasting and affordable solution to safeguard their products' integrity during transportation and storage.

Comments