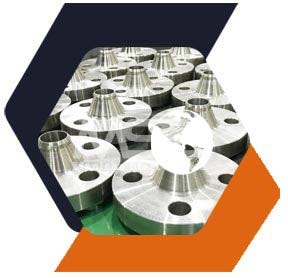

Flanges must be carefully selected as they can become a weak point in the system. You can know about Stainless Steel Flanges manufacturers in India. On the other hand, stainless steel flange fittings can endure the heat without deforming or warping.

What are Duplex flanges?

Compared to conventional austenitic 304 and 316 stainless, this austenitic-ferrite stainless version has a more robust stress corrosion cracking resistance but poorer toughness and impact strength. Choose among the top Duplex Flanges manufacturers in India. Heat treatment of high-pressure boiler pipes includes heating and chilling to increase toughness, hardness, and wear resistance.

Quenching is one of the processes in the heat treatment process. The metal tube is more durable and powerful than other forms of tubing. As a result, it has many uses in structural industries. Metal tubes have a high degree of rigidity and making it more useful for industrial purposes.

Why has the demand for Duplex Stainless Plate increased?

Alloy 2507 produced by Super Duplex Flanges manufacturers in India is a super duplex stainless steel with a chromium content of 25%, a molybdenum content of 4%, and a nickel content of 7%. The high amounts of chromium, molybdenum, and nitrogen give exceptional pitting, crevice, and overall corrosion resistance. The impact resistance is also relatively strong. Because of the danger of a loss in toughness, Alloy 2507 is not recommended for applications that require protracted exposures to temperatures above 570°F.

Alloy 2507 is a very strong super duplex stainless steel with a chromium content. The alloy 2507 steel has high thermal conductivity and a low coefficient of thermal expansion, making it resistant to chloride stress corrosion cracking. The high amounts of chromium, molybdenum, and nitrogen give exceptional pitting, crevice, and overall corrosion resistance.

What are Titanium Grade 2 Flanges?

Grade 2 Titanium blind flanges produced by Titanium Flanges manufacturers in India are available in different sizes ranging from 1/2" (1.26 lbs) to 24". Dimensional tolerances meet ASME B16.5, and flange bore diameters match ASME B36.9 wall pipe standards. Other bore diameters can be ordered on a custom basis.

Different surface finishes for gaskets can be ordered on a custom basis. Electrochemical etching is used to label titanium flanges according to ASME B16.5 permanently. Titanium flange weights are estimated using a density of — 163 pounds per cubic inch. Titanium Industries has a large selection of Grade 2 Titanium. The Threaded Flange manufacturers In India also produce the best products.

Final thoughts

Carbon steel press-fit pipework is widely used in closed-circuit heating and compressed air systems. The primary source of oxidative corrosion, air or oxygen, is eliminated with a closed-circuit heating system. Carbon steel gives any material used to make a high tensile strength. It can be bent and stretched into any shape and retain its power.

Instead, it emphasizes how each piping material has advantages and disadvantages and how it is appropriate for some applications but not for others. Carbon Steel’s lower cost is perhaps the most critical factor in choosing it over one of the stainless steel grades.

Comments