In our age of technology, where everything is constantly changing, there is a need for new methods due to automation, management of large amounts of data, and systems integration. One such method that has become quite popular is the use of an industrial single-board computer (SBC). These computers are small, flexible, and powerful, as they are made for a particular industry and work effectively in all extreme conditions. Almost every industry has been revolutionized by single-board computers running business processes from automation to data-centric.

In this blog, we, at ITG India, will get you acquainted with single-board computers. We will help you understand the “what, how, and why”, the different types available, and their applications. If you want to up the level of automation in your plants or you are on a hunt for solid computers, an SBC will help in excelling what you do.

What is an Industrial Single Board Computer?

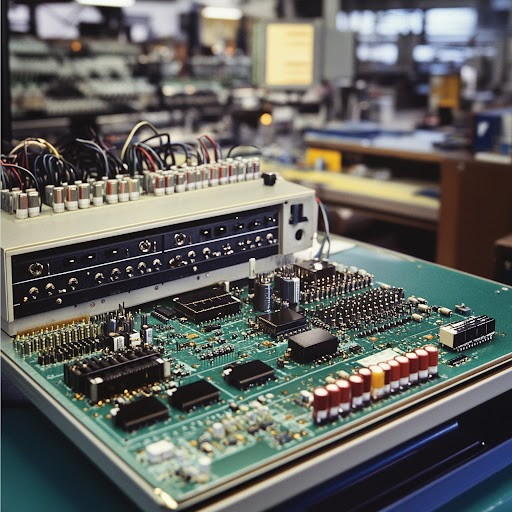

An industrial single-board computer (SBC) is a complete computer, which is all realized on a single circuitry board. Unlike traditional computers that have their parts like motherboard, CPU, RAM, storage, and so forth separately from each other, SBC configuration combines all into one compact unit. Nevertheless, these are SBCs made to be used in factories; they are designed to be tougher and to operate under severe conditions including high and low temperatures, and dust and vibrations.

Industrial SBCs are often used in applications where space is at a premium or where a standard computer installation is not feasible. Despite their dimensions, these devices can boot modular operating systems, such as Linux, or Windows, or run a real-time operating system (RTOS), and a number of industrial interconnects can be integrated for input/output purposes. This makes them an ideal candidate for applications in flexible automation and control systems, thereby enabling more innovations in industries. Multi-functional single-board computers are embedded in several definitional components. One of these components is the processor, also known as the CPU which is responsible for every form of computing duty task. In addition, to the processor, other components such as random access memory (RAM), main storage, and IO connectors for interconnecting with other equipment such as sensors, controllers, monitors, etc., are attached to the CPU.

What Are The Working Principles Of Single Board Computers?

A single-board computer, as the name implies, integrates all the peripherals found in a computer unit into a circuit the size of a card. The central processing unit is the most important part of a single-board computer as it is the active component that performs computing activities. In addition to the CPU, there are additional components found such as RAM which provides memory, flash storage which holds data, and various I/O ports that connect to external devices like sensors, controllers, or screens.

Functional SBCs are built to have minimal power consumption compared to personal computers, i.e. industrial single-board computers can perform tasks without using a lot of power. Besides, they come with several operational voltage ranges including very low DC inputs which makes them fit for use even in far places that are not connected to any power grid.

They use embedded operating systems (like Linux or Windows) that allow these computers to perform computing functions and offer data processing on a timely basis. These SBCs also include various Ethernet, USB, GPIO, serial, and other connections facilitating their use in industrial automation products and complex control systems. The SBCs are also robust and can perform their functions appropriately even when the conditions are unfavorable which is a requirement in industries.

The Uses Of Industrial Single Board Computers

Industrial SBCs are adaptable and can be integrated into various applications. Some of the most frequent applications are given below:

1. Industrial Automation

It is known that one of the main application fields of SBCs is industrial automation. Since such computers can conduct data and machinery control, they are frequently located on factory floors — where they assist in the operation of production machinery, the surveillance of the process and quantity of the performed work, and the management of other devices. Due to their compact size, they can be integrated into devices where confined space is a challenge, while fond durable materials make them resilient even in the sobering harsh zone of industry.

2. Data Collection Systems

Industrial single-board computers (SBCs) are widely used for the collection of data and real-time monitoring applications. These computers are integrated with numerous sensors and instruments enabling real-time data capturing and processing capabilities, which is very essential in sectors such as manufacturing, energy, and transportation. This information can then be used to improve process control, estimate maintenance requirements, and eliminate unnecessary expenses incurred in running the systems.

3. Embedded Systems

SBCs are preferred in embedded systems where devices are designed for limited applications such as in control of robots, embedded controllers, and security systems. Since these chips can also run real-time operating systems, they can execute tasks of utmost importance within the shortest period of time possible.

4. IoT (Internet of Things)

SBCs are the essential component of IoT devices that require computing and connectivity capability in applications. They are utilized in smart factory automation systems, systems for monitoring energy consumption, and gateways in industrial applications of IoT that connect the machines to the cloud for intelligent and effective operation of the systems.

5. Industrial Panel PCs

An industrial panel PC is a multi-purpose processor which mainly comprises of a single board computer together with a touch screen and a strong casing. Such tools are effectively applied in production sites, storehouses, or even in a control room where the user is required to facilitate and supervise a production system. They are rather rugged and, hence can withstand harsh conditions.

6. Automated Test Equipment

SBC boards are frequently used in automated test equipment for electronics, semiconductor devices, and other product tests. These provide parameter control, data archiving, and processing in real-time allowing producers to keep product quality high.

Types of Industrial Single Board Computers

Compact and efficient industrial single-board computers are not all alike, and they have been developed to meet the differing industrial requirements. Here are some common types of industrial SBCs:

1. ARM-based SBCs

ARM-based single-board computers are oriented towards developing energy-efficient systems. They are extensively used in embedded systems — devices that connect to the internet, and handheld computing. The processors within the ARM family tend to consume much less power than others which makes them perfect for use in areas where the application has to be mobile or deployed in remote locations for longer duration operating on battery.

2. X86 based SBCs

X86-based SBCs have their computing cores at a higher level and are able to run installations of Windows and Linux operating systems. These are found in more challenging activities like industrial panel computers, and automation systems where power and inter-grade functions are necessary. These can also have extra controllers like PCIe and SATA which are used for further industrial configurations and complex requirements.

3. GPU-based SBCs

SBCs that have a graphics processing unit are preferable for systems used for complicated graphic visualizations, machines that incorporate artificial intelligence, and deep learning, or systems that rely on visual checking. The systems are designed in a way that there are high-performance chips in addition to a computer which can be used for image processing and analysis of huge data in real time.

4. Rugged SBC

Rugged SBCs are designed to withstand extreme conditions including extreme heat or cold, heavy shaking, and even dusty conditions. These machines are deployed in industries such as mining oil and gas drilling, and military services where the physical strength of the equipment is crucial.

End Note

Industrial single-board computers are now crucial to the advancement of automation and industrial operations. Their small size coupled with strong capabilities and wide usefulness range makes them appropriate for many functionalities such as data collection to operation of industrial panel computer.

At ITG India, we work tirelessly to provide industrial automation solutions that include, but are not limited to, the supply of single board computers (SBCs) among other industrial automation products. Drawing on our experience with top international companies like Advantech, ATEN, AMobile, and many others, we are able to provide you with dependable and durable solutions such as embedded systems, and industrial panel PCs among others. Whether you want to add new systems to your operations or enhance the existing ones, ITG supports your path with advanced technologies and services of the highest quality.

If you are looking forward to modernizing your manufacturing processes with state-of-the-art machinery such as industrial single-board computers or other automation processes, reach out to ITG India today. Because of us, you don’t have to worry as we provide quality services in all aspects of automation and industrial supplies including IT services.

Reference Link: https://itgindiatelecom.medium.com/all-about-industrial-single-board-computer-types-uses-and-more-531593fee3d7

Comments