3D laser scanning services are taking over many industries. They turn complex projects into simpler, more accurate tasks. As technology advances, these services become faster, more precise, and easier to manage. For any business looking to improve its workflows, adding laser scanning can lead to better outcomes and lower costs.

What Are 3D Laser Scanning Services?

Definition and Basic Principles

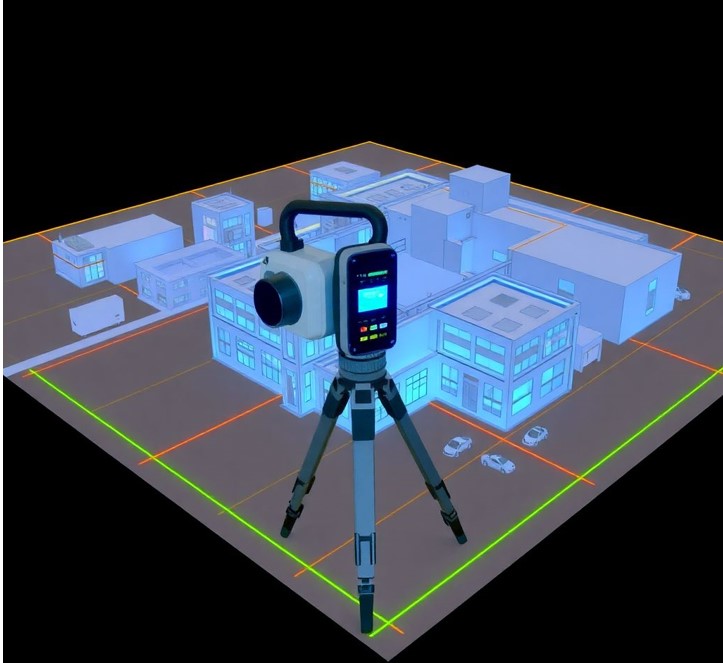

3D laser scanning is a tech that uses lasers to capture the shape and size of real-world objects. It creates a detailed map called a point cloud, showing every curve and edge. Unlike traditional measurements that need tape and guesswork, laser scanning delivers high accuracy fast. It produces a digital version of physical space or objects, which helps in modeling, planning, and analysis.

Types of 3D Laser Scanners

- Terrestrial laser scanners: Stand on the ground and cover large areas. They are best for building scans, infrastructure, and outdoor projects.

- Aerial laser scanners (LiDAR drones): Use drones equipped with lasers to reach hard spots like mountain tops or tall structures.

- Handheld and portable scanners: Small, easy-to-move devices. These are ideal for quick measurements, interior spaces, or complicated objects.

How 3D Laser Scanning Works

The process starts with shooting laser beams at the target. The scanner records how long each laser takes to bounce back. This data forms a point cloud. Software then processes these points, turning them into models that can be viewed or edited in CAD or BIM programs. It’s a mix of hardware and software working together for precise results.

Key Applications and Industry Use Cases

Construction and Civil Engineering

3D laser scanning speeds up site surveys and as-built documentation. It helps track project progress and catch mistakes early. Large infrastructure projects like bridges and highways depend heavily on these scans. They make sure everything fits perfectly and helps prevent costly errors later.

Manufacturing and Industrial Inspection

In manufacturing, laser scanning checks parts for errors, speeds up reverse engineering, and guides maintenance. For example, aerospace companies use it to get exact measurements of complex parts. That way, they improve precision and reduce waste.

Cultural Heritage and Archaeology

3D scans of ancient ruins and artifacts protect history. They allow virtual preservation, easy sharing, and detailed analysis. Museums and archaeologists use laser scanning to study sites without risking damage. It saves priceless pieces from deterioration while giving everyone access.

Oil & Gas, Energy, and Power Plants

Plants need regular inspections to stay safe. Laser scans help spot issues quickly and reduce inspection time. They also assist in retrofitting old plants with new technology. Some companies report cutting inspection times by half, making safety checks faster and less risky.

Other Sectors

- Film and entertainment: Useful for digital art and special effects.

- Insurance: Helps assess damage after accidents or disasters.

- Mining and exploration: Finds resources and maps underground areas without risky digs.

Benefits of Using 3D Laser Scanning Services

Superior Accuracy and Precision

Laser scanning captures every detail within millimeters. This high accuracy helps avoid mistakes and improves project quality. When accuracy matters most, laser scanning shines.

Speed and Efficiency

Compared to manual measurements, laser scans take a fraction of the time. Large sites can be scanned in hours instead of days. This quick turnaround helps meet tight deadlines and speeds up project delivery.

Enhanced Data Management

The data can easily be loaded into CAD or BIM systems. This creates smoother workflows, better collaboration, and clearer project documentation. It’s like having a detailed map ready to use at any step.

Cost Savings

You can cut costs by reducing rework and errors. Accurate scans help plan resources better and avoid unnecessary work. Over time, this technology pays for itself.

Improved Safety

Scans can be done remotely, keeping workers out of hazardous zones. It’s safer and faster than sending teams into risky environments, especially at high or unstable sites.

Selecting the Right 3D Laser Scanning Service Provider

Factors to Consider

- Experience: Choose a company with a proven track record in your industry.

- Equipment: Make sure they use modern scanners suited to your project.

- Data security: Trustworthy vendors protect your data and privacy.

Questions to Ask Potential Vendors

- How fast will you deliver the results?

- What formats do you provide the data in?

- Do you handle post-processing and editing?

Cost Considerations

Understand how pricing works—by project, hourly, or data volume. Compare quotes and see which offers the best ROI. Remember, investing in quality often saves money long-term by preventing costly errors.

Future Trends and Innovations in 3D Laser Scanning

Integration with AI and Machine Learning

Future scans will automatically detect errors and improve data quality using AI. This reduces manual work and speeds up project timelines.

Increased Use of Drones and Aerial Scanning

Drones make reaching tough spots easy. They expand the horizons for laser scanning—think rugged terrains or tall structures.

Enhanced Resolution and Speed

Newer scanners will capture higher detail in real time. Expect faster scans with clearer, more accurate data.

Broader Industry Adoption

More sectors are discovering the benefits of laser scanning, from agriculture to construction. It’s no longer just for big projects but for daily operations.

3D laser scanning services are changing how industries work. They bring speed, precision, and safety to projects that once took days or weeks. Picking the right provider means better results and more savings. Companies should explore these tools to solve challenges and improve their processes. The best way forward? Start with a needs assessment or a small pilot to see how laser scanning can work for your business. Embrace the future—accuracy and efficiency are just a scan away.

Comments