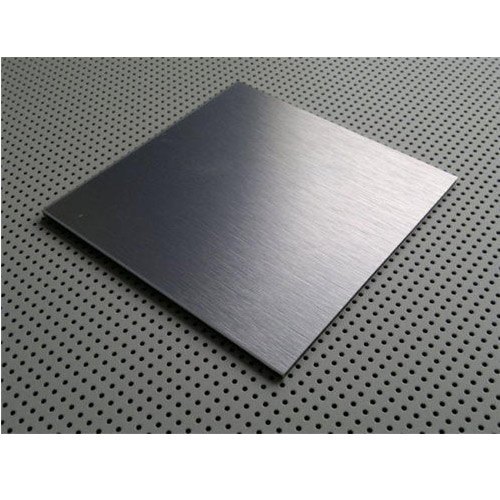

A form of surface finish called a grinding finish is applied using different abrasive machining techniques. The material, polisher, finishes, and patterns all affect the different grinding patterns. It is possible to mix and match, apply in layers, or arbitrarily design these patterns and finishes, giving architects more creative license. There are several industries that use polishing or grinding as a machining technique, from small bits of precise equipment to massive goods like aircraft. Because it can accommodate a variety of designs, the polished or ground finish of metal has been chosen for a variety of locations, including curtain walls, interiors and exteriors, fixtures, and monuments.

Features of grinding finish on sheets

Offering a high-grade polished finish with significant quality control knowledge.

Bespoke polishing finishes and the creation of new polishing finishes are supported. Various polishing patterns are supported.

Small lots, large panels, oleophobic coatings, passivation coatings, and combinations with other finishes can all be accommodated.

Finish in a way that improves the look.

Purpose of grinding finish

The grinding finish on stainless steel grinding finish sheets has been favored in architecture as a finish that could make use of the beneficial characteristics of the material and for its architectural freedom. The machining procedure of the same name is when polishing or grinding finishes first appeared. To achieve the desired surfaces, a variety of materials, including metal, stones, and wood, are ground. Grinding or polishing can smooth or roughen the surface, or change the surface by a couple of millimeters, to obtain the desired functionality or aesthetic. The quality of the surface, the adjustment of corrosion resistance after welding, the improvement of the slipperiness of the parts, the improvement of the shine, and other aesthetics are all adjusted for in metal architecture using the grinding or polishing finish.

Comments