Introduction

In recent years, the modular robotics market has emerged as a transformative force in industries worldwide, revolutionizing manufacturing, logistics, healthcare, and more. These robots, designed to be adaptable, flexible, and scalable, are reshaping production processes, offering significant advantages in efficiency, precision, and customization. However, while the adoption of modular robotics presents immense opportunities for innovation, it also raises several concerns about the future of labor markets.

This article explores the profound impact of modular robotics on labor markets, focusing on the opportunities and challenges it presents to workers, businesses, and society at large.

What is Modular Robotics?

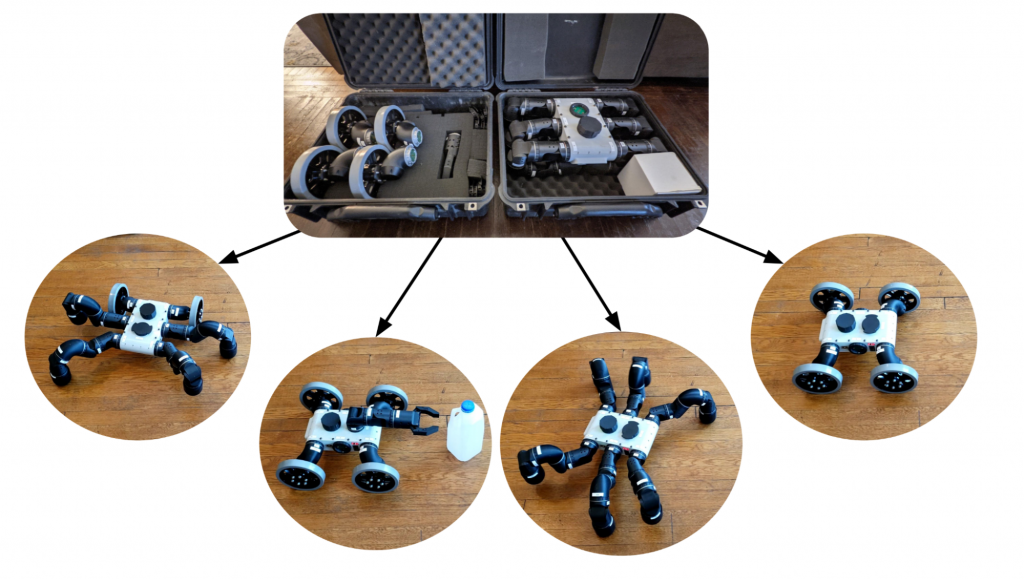

Modular robotics refers to the use of robots made up of self-contained, interchangeable modules or components that can be reconfigured to perform different tasks. These robots can be easily adapted to changing production needs, making them highly versatile and cost-effective solutions for industries requiring flexibility and scalability.

Unlike traditional industrial robots that are designed for specific tasks, modular robots can be quickly reconfigured or upgraded to meet new demands. This adaptability is especially valuable in dynamic environments where production processes evolve rapidly.

The Role of Modular Robotics in Modern Industries

Modular robots are being deployed across a wide range of industries, including:

1. Manufacturing and Assembly

In manufacturing, modular robotics enables companies to streamline assembly lines by creating customizable robotic systems that can adapt to different product designs or production volumes. For instance, modular robotic arms can work alongside human workers to increase the speed and accuracy of assembly operations. With the ability to reconfigure systems easily, businesses can quickly adjust production lines in response to shifting consumer demands.

2. Logistics and Warehousing

In logistics and warehousing, modular robots are transforming the way goods are sorted, stored, and transported. Automated guided vehicles (AGVs) and robotic sorting systems are often used to transport items from one location to another within warehouses. By using modular components, these robots can be reprogrammed to handle various types of inventory and accommodate fluctuating workloads.

3. Healthcare

Modular robotics is also making waves in the healthcare sector. For example, modular robotic systems are used in surgical applications where precision and flexibility are required. These robots can be adapted for various procedures, ensuring high precision and reducing human error. Additionally, modular robots are being explored for use in rehabilitation and elderly care, where their ability to be customized for individual needs is particularly beneficial.

4. Agriculture

The agricultural sector is benefiting from the deployment of modular robots that assist with planting, harvesting, and crop management. These robots can be reconfigured to suit different crops or farming techniques, making them a versatile solution for modern agriculture.

Opportunities Presented by Modular Robotics

1. Increased Productivity and Efficiency

One of the most significant benefits of modular robotics is its potential to boost productivity and efficiency across industries. With their ability to perform repetitive tasks at high speeds with great precision, these robots can reduce downtime, minimize errors, and increase the overall throughput of production processes. By automating certain tasks, companies can lower operational costs and improve profitability.

2. Customization and Flexibility

The modular nature of these robots allows businesses to create solutions tailored to their specific needs. For example, a company might require a robot that can handle a variety of tasks within the same production line, such as assembly, testing, and packaging. With modular robotics, businesses can easily customize and reconfigure robots to meet their evolving requirements, which is a significant advantage in industries where product specifications and market demands change frequently.

3. Reduced Dependency on Human Labor

Modular robots can help alleviate the strain on human workers by taking over dangerous, repetitive, or physically demanding tasks. For example, robots can be used in hazardous environments, such as chemical plants or construction sites, where human workers may be at risk. This reduces workplace accidents and minimizes the exposure of workers to harmful conditions, creating safer working environments.

4. Addressing Labor Shortages

In certain industries, there is a growing concern about labor shortages, especially as the global workforce ages and fewer people enter trades like manufacturing and agriculture. Modular robotics can help bridge this gap by filling in the roles left vacant by humans. These robots can work 24/7, helping companies maintain production levels even when human labor is in short supply.

5. Creation of New Jobs and Skill Development

While modular robotics may reduce the need for certain manual labor jobs, it also creates new opportunities in areas such as robot maintenance, programming, and system design. The need for skilled workers to manage and optimize these robots is growing, creating job opportunities in robotics engineering, data analysis, and machine learning. In turn, this shift encourages the development of new skills and the upskilling of workers to meet the demands of a more automated workforce.

Challenges Posed by Modular Robotics on Labor Markets

1. Job Displacement and Unemployment

As modular robotics becomes more prevalent, the fear of job displacement grows. Repetitive and low-skilled jobs in manufacturing, warehousing, and even logistics may be at risk as robots take over these tasks. This shift in labor dynamics could lead to increased unemployment, particularly among workers whose skills are not aligned with the demands of the new robot-driven economy.

Workers in industries that rely heavily on manual labor may struggle to find new employment opportunities without extensive retraining or upskilling. The displacement of low-wage, low-skill workers can create economic inequality and social unrest if proper measures aren’t taken to support affected workers.

2. Economic Inequality

While modular robotics offers great potential for businesses to increase profits and productivity, it can also exacerbate existing economic inequality. Large companies that can afford to invest in robotic technologies are likely to reap the most significant rewards, while smaller businesses may struggle to adopt these systems due to high initial costs. This divide can create a widening gap between the "robot-rich" companies and smaller enterprises, leading to further wealth disparities.

Additionally, workers with lower levels of education or experience may be excluded from new job opportunities created by modular robotics, as they may lack the technical skills required to operate or maintain advanced robotic systems. Consequently, there is a risk that the benefits of modular robotics may not be equally distributed across all sectors of society.

3. Job Re-skilling and Education

To fully realize the benefits of modular robotics while mitigating job displacement, there must be a concerted effort to invest in education and re-skilling programs. As certain job roles are automated, workers need to be equipped with new skills that align with the evolving job market. For example, training in robotics programming, machine learning, and data analysis can prepare workers for the high-skill jobs created by robotics.

However, providing such training on a wide scale presents challenges, particularly in regions with limited access to quality education or training programs. Governments and businesses must collaborate to ensure that workers are adequately prepared for the future of work, ensuring a smooth transition into the era of automation.

4. Public Perception and Acceptance

The widespread adoption of modular robotics may also face resistance due to public skepticism about the role of robots in the workforce. Workers and unions may be concerned about job security and the potential dehumanization of work, particularly in industries where human labor has been the norm for generations. Overcoming this resistance will require clear communication about the benefits of modular robotics, such as the creation of new job opportunities, safer working environments, and improved productivity.

Strategies to Mitigate the Negative Impact of Modular Robotics

1. Government Policies and Social Safety Nets

Governments can play a crucial role in addressing the challenges posed by modular robotics by implementing policies that support workers affected by automation. This may include funding retraining programs, offering unemployment benefits, and providing incentives for businesses that invest in worker education.

Additionally, governments can explore the implementation of universal basic income (UBI) or other social safety nets to ensure that displaced workers are financially supported during the transition period.

2. Collaboration Between Industry and Education

Businesses, educational institutions, and government organizations should collaborate to create educational programs that equip workers with the skills needed to thrive in a robot-driven economy. This could involve partnerships between universities and robotics companies to develop curricula focused on robotics engineering, automation, and AI.

3. Promoting Inclusive Technological Growth

Efforts should be made to ensure that the benefits of modular robotics are shared equitably across society. Smaller businesses, for example, could be supported through subsidies or loans to help them adopt robotics technologies. Additionally, workers in lower-skilled jobs should have access to training programs that allow them to transition into higher-skilled positions in the robotics industry.

Conclusion

Modular robotics is poised to redefine the landscape of labor markets across the globe, offering both opportunities and challenges. The increased efficiency, flexibility, and customization that modular robots provide have the potential to drive economic growth and innovation across industries. However, the rise of automation also raises concerns about job displacement, economic inequality, and the need for re-skilling workers.

As we move into an era of increased automation, it is essential that businesses, governments, and educational institutions work together to address these challenges. By doing so, we can ensure that the benefits of modular robotics are shared broadly and that workers are equipped with the skills they need to thrive in the evolving workforce. Only then can we fully harness the transformative power of modular robotics while minimizing its negative impact on labor markets.

Comments