Ever wonder what makes factories whir like clockwork, power plants hum day and night and water treatment plants operate with precision? Offstage, working behind the scenes are Industrial Control Systems (ICS).

From manufacturing to power, transport, or even food processing, Industrial Control Systems are the cybernetic minds that oversee, control and optimize all industrial processes.

Let’s look at what these systems are, why they’re significant and what their key components are like in our own era.

What Are Industrial Control Systems?

In plain language, ICSs are hardware and software combined systems employed to automate and control industrial operations. From turning on a conveyor belt to controlling the transmission of electricity from city to city, ICS does everything precisely and safely.

They manage real-time observation and automated control through sensors, machines and operator inputs. They are the industrial world’s version of the central nervous system, sensing, processing, and responding continuously.

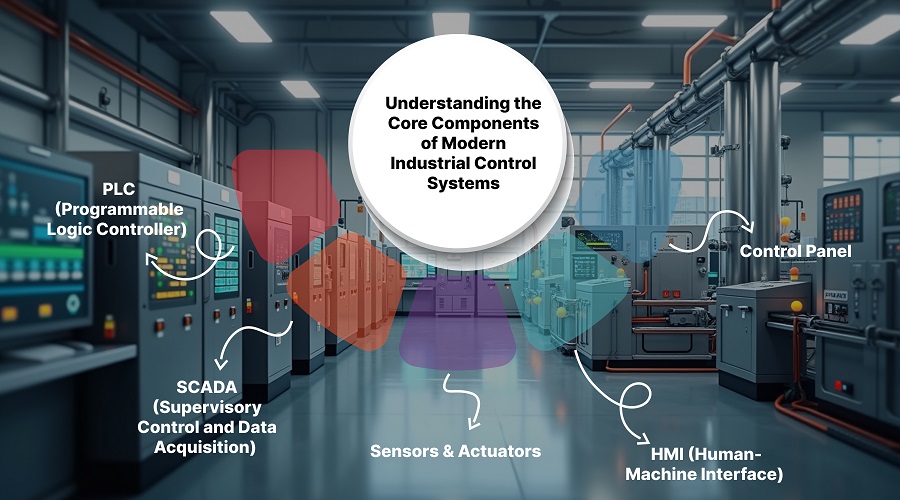

Key Components of ICS

- SCADA (Supervisory Control and Data Acquisition)

One control center for remote operations — think pipelines, power lines, or mass production. SCADA pulls data from distant locations, so operators never have to leave the office to view issues and send control commands.

- PLCs (Programmable Logic Controllers)

These resilient little computers run specific tasks: they read sensor inputs, run pre installed logic and control machines to move. Fast, flexible and built to thrive in tough conditions, PLCs are the backbone of shop floor automation.

- HMIs (Human Machine Interfaces)

Your dashboard or touchscreen, where operators look to see real-time information, get warnings and take control manually when needed. That’s where human judgment and automated action intersect.

- RTUs (Remote Terminal Units)

Similar to PLCs but designed for dispersed setups as oil fields, solar farms, or water wells. RTUs collect local sensor data and relay it back to SCADA, bridging the gap between remote assets and your control hub.

- Industrial Networks

All these pieces need to talk to each other. Protocols like Modbus, Profibus, and Ethernet/IP form the digital highways that carry commands and data securely and reliably.

What’s New in ICS?

- IoT Integration makes systems smarter by tapping into extra sensors and devices, letting you predict equipment hiccups before they happen.

- Built in Cybersecurity locks down every layer — because more connectivity means more targets.

- Cloud and Remote Access let you check in or even tweak operations from anywhere with a secure link.

- AI and Machine Learning sift through mountains of data to spot subtle performance drifts and optimize processes on the fly.

Why It Matters

ICS aren’t just technical curiosities; they’re the invisible force behind nearly everything we rely on. As industries digitalize, having folks who truly understand these systems is crucial. Companies need experts to design and maintain them; governments must defend them from hackers; and the rest of us benefit from the steady flow of goods, power and water.

Everyday Encounters with ICS:

- In a car factory, PLC driven robots weld and assemble.

- At your local waterworks, SCADA keeps the taps flowing safely.

- The power in your home stays balanced thanks to control systems in the grid.

- Traffic lights and metro trains run on split-second commands from specialized controllers.

Conclusion

Industrial Control Systems may not grab headlines, but they quietly keep our world in motion. By blending PLCs, SCADA, HMIs, RTUs and rock solid networking, they make industries faster, safer and more efficient. As automation and connectivity grow, these systems will only become more essential and more sophisticated.

Scholars, ensure your Literature Review on modern industrial control systems stands out with originality. Use our advanced plagiarism check tool to maintain academic integrity and produce research you can confidently publish.

FAQs

1. Which industries rely on ICS?

Almost all of them like manufacturing, energy, water treatment, oil and gas, transportation, food processing, and more.

2. How do SCADA and PLCs differ?

SCADA gives you a big-picture view and remote control across large areas, while PLCs handle local, machine-level tasks.

3. Are these systems at risk of cyberattacks?

Older setups can be vulnerable. Modern ICS now include encryption, firewalls and secure access to stay protected.

4. What role does IoT play?

IoT adds more sensors and data streams, enabling real-time analytics and predictive upkeep.

5. Can you operate ICS remotely?

Yes. Secure cloud platforms let you monitor and even adjust systems from virtually anywhere.

Comments