Understanding Shrink Wrapping Machines in Guwahati

Shrink wrapping machines are instrumental in the packaging industry for providing a secure, protective, and visually appealing wrap to various products. In Guwahati, these machines are utilized across different sectors, including food packaging (like biscuits, soaps, and ice candies), thanks to their efficiency and versatility. Let's explore how shrink wrapping machines function and contribute to streamlined packaging solutions.

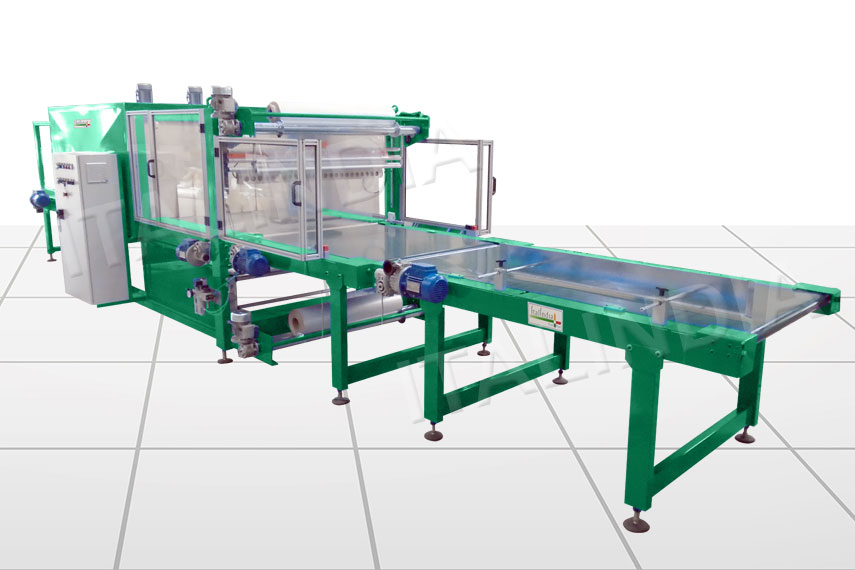

1. Preparation and Setup: The process begins by setting up the Shrink Wrapping Machine in Guwahati according to the specific packaging requirements. This includes adjusting the heat settings and conveyor speed to suit the type and size of the products being wrapped.

2. Product Loading: Products that have already been packaged (such as those from Pouch Packing Machines, Milk Packaging Machines, or Cap Sealing Machines) are loaded onto the conveyor belt of the shrink wrapping machine. This can include pouches of liquid products filled by Liquid Filling Machines in Guwahati or sealed containers from cap sealing processes.

3. Film Feeding: The shrink wrapping machine feeds a roll of shrink film, sourced from Packaging Material Suppliers in Guwahati, which is then unwound and draped over the products on the conveyor belt.

4. Sealing and Shrinking: As the products move through the machine, the film is sealed around them using heat. This heat can come from various sources, such as heated rollers or heat guns, depending on the machine's design. The sealed film is then subjected to heat again, causing it to shrink tightly around the products, creating a snug and protective wrap.

5. Cooling and Finalization: After shrinking, the wrapped products pass through a cooling zone or are cooled with air to ensure that the film sets in place securely. This cooling phase is crucial for maintaining the integrity of the wrap and preventing any distortions.

6. Quality Control and Inspection: Shrink wrapping machines often include sensors and mechanisms for quality control, detecting any irregularities or incomplete seals. Any faulty wraps are identified and removed from the production line, ensuring only properly wrapped products are dispatched.

7. Integration with Packaging Lines: Shrink wrapping machines can be integrated seamlessly with other packaging equipment, such as Vacuum Packing Machines in Guwahati, to provide additional protection or enhance the presentation of packaged products.

Conclusion: Shrink wrapping machines in Guwahati offer an efficient and effective solution for packaging a wide range of products, from food items like biscuits and ice candies to non-food items like soaps. Their ability to provide a secure and visually appealing wrap makes them indispensable in modern packaging operations across industries.

Comments