Gazing into the future of the glass manufacturing industry is like peering through a crystal ball – shimmering with possibilities and veiled in a touch of uncertainty. However, by analyzing current trends, technological advancements, and economic forces, we can make educated predictions about what the coming decade holds for this versatile material.

Growth Trajectory: A Sustainable Climb

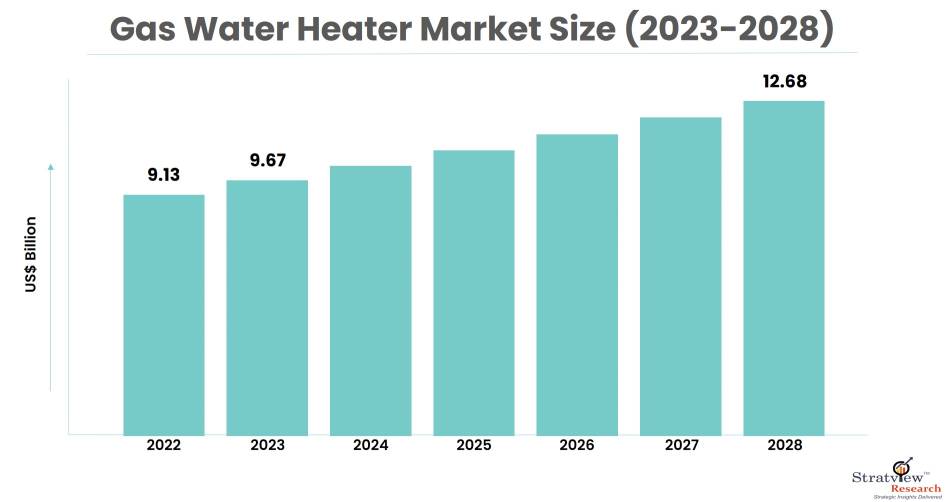

Market analysts predict a steady rise in the global glass manufacturing market in the coming decade. According to Stratview Research, the global glass manufacturing market size was valued at USD 111.62 billion in 2022 and it is projected to reach USD 149.6 billion in 2028, growing at a CAGR of 5% during forecast period of 2023-2028. Several key drivers will propel this growth:

- Urbanization Boom: The relentless march of urbanization, particularly in developing economies, will fuel demand for flat glass used in construction projects like skyscrapers and residential buildings.

- Greener Packaging Solutions: Consumers and businesses are increasingly environmentally conscious, driving the demand for sustainable packaging materials. Glass, with its recyclability and inert properties, is poised to benefit from this trend.

- Technological Advancements: The integration of advanced technologies like self-cleaning coatings and smart glass functionalities will add value to glass products and expand their application areas.

- Focus on Energy Efficiency: As energy costs rise and environmental concerns intensify, the demand for energy-efficient building materials will surge. High-performance glass solutions that optimize thermal insulation will be in high demand.

Market Segmentation: Evolving Landscape

While the overall market is expected to grow, the dominance of specific segments might shift:

- Flat Glass: Flat glass is likely to maintain its position as the largest segment, driven by the aforementioned construction boom. However, a growing focus on energy efficiency might lead to increased demand for specialized coatings and high-performance glazing solutions.

- Container Glass: The container glass segment is expected to witness steady growth, primarily driven by the demand for sustainable packaging solutions in the food and beverage industry. Regulations promoting refillable glass containers could further bolster this segment.

- Specialty Glass: The specialty glass segment is poised for significant growth due to its diverse applications in electronics, pharmaceuticals, and automotive industries. Advancements in nanotechnology and glass-ceramics will open doors for even more innovative specialty glass products.

Regional Dynamics: Shifting Power Balances

The regional landscape of the glass manufacturing market is expected to undergo a subtle shift in the coming decade:

- Asia Pacific: This region is likely to remain the dominant player, driven by rapid urbanization and infrastructure development in countries like China and India. However, stricter environmental regulations might pose challenges for some manufacturers.

- Developed Economies: North America and Europe are expected to witness slower growth, but these regions will continue to be important markets for high-performance and specialty glass products. Focus on technological innovation and sustainability will be crucial for established players in these regions.

- Emerging Markets: Emerging economies in Africa and Latin America are expected to witness a surge in glass manufacturing as construction activities and consumer spending rise. These markets present lucrative opportunities for established players seeking global expansion.

Sustainability Concerns: A Greener Future

Sustainability will remain a paramount concern for the glass manufacturing industry in the coming decade. Here's what we can expect:

- Closed-Loop Recycling: Closed-loop recycling systems will become increasingly prevalent, allowing manufacturers to efficiently convert post-consumer and industrial glass waste back into usable raw materials. This minimizes reliance on virgin resources and reduces the industry's environmental footprint.

- Alternative Raw Materials: Research into alternative raw materials will continue, with explorations of using waste products or byproducts from other industries in glass production. This reduces reliance on traditional resource extraction.

- Energy-Efficient Furnaces: The adoption of electric melting furnaces and other energy-efficient technologies will be crucial for reducing the carbon footprint of glass production.

Technological Advancements: Pushing the Boundaries

Technological advancements will be a game-changer for the glass manufacturing industry:

- Nanotechnology: Nanotechnology will enable the development of next-generation glass with enhanced properties like self-healing capabilities, superior scratch resistance, and improved thermal insulation.

- Smart Glass: Smart glass with integrated sensors and electronic circuits will become more prevalent, offering functionalities like self-dimming, dynamic displays, and improved energy efficiency in buildings.

- 3D Printing of Glass: 3D printing technology has the potential to revolutionize glass manufacturing, allowing for the production of complex shapes and customized glass products.

Comments