Laser cut staircase panels cost can vary widely depending on specifications. On average, prices range from $80 to $400 per panel, but that’s only a general estimate. The actual price depends on materials, design intricacy, finishing options, panel size, and customization.

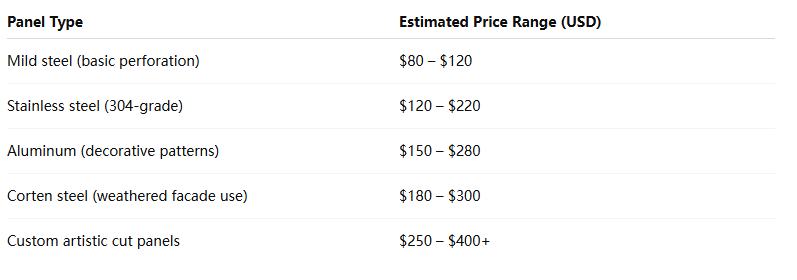

Below is a basic market breakdown:

It’s important to note that this price typically excludes shipping, taxes, and installation. While some manufacturers include laser programming and basic finishing in their pricing, others treat these as add-ons.

What Key Factors Influence Laser Cut Staircase Panels Cost?

Understanding what drives the cost helps buyers avoid surprises. Here's a breakdown of the main cost drivers:

Material Selection

Material choice is the most influential factor affecting cost. Each material has distinct physical properties, durability, and aesthetic appeal:

- Mild Steel: The most affordable option, suitable for industrial environments.

- Stainless Steel: Offers corrosion resistance and is ideal for indoor and outdoor architectural designs.

- Aluminum: Lightweight, rust-resistant, and slightly more expensive due to raw material costs.

- Corten Steel: Preferred for weathered outdoor designs, higher in price.

- Galvanized Steel: Provides rust resistance at a lower cost than stainless steel.

Each material's price per square meter will directly impact the overall laser cut staircase panels cost.

Panel Size and Thickness

Laser machines adjust cutting power depending on material thickness. Larger or thicker panels mean:

- More cutting time

- Higher energy consumption

- Increased raw material usage

- Additional support for transportation or installation

For example:

- A 3mm thick panel might cost 20–30% less than a 6mm thick panel of the same material and design.

Design Complexity

The more intricate the design, the higher the cost. Simple geometric patterns or repeated perforations are quicker and cheaper to cut. On the other hand:

- Artistic patterns with curves, tight tolerances, or layered detailing require extensive CNC programming and longer cutting times.

- High-resolution designs also create more waste, which adds to material cost.

Type of Finish

The surface finish affects the panel's appearance and lifespan. Common finishes include:

- Raw steel: No additional cost but prone to rust.

- Powder coating: Durable, weather-resistant, available in custom colors.

- Anodizing (for aluminum): Offers protection and color options.

- Painted finishes: Lower durability than powder coating, but lower cost.

- Brushed/polished stainless steel: For high-end interior applications.

Finishing can add $20–$100 per panel depending on the type.

Quantity Ordered

Higher order volumes generally result in lower unit prices due to economies of scale:

- Setup costs (machine programming, tooling) are distributed over more units.

- Bulk raw material purchases lower per-panel material cost.

- Freight per panel drops when shipped in bulk.

Small, one-off orders tend to be more expensive per unit.

Shipping and Location

Shipping fees depend on:

- Panel size and weight

- Destination country

- Urgency (air vs. sea freight)

Panels are often shipped flat-packed but still require protective packaging. International duties and customs also add 10–25% depending on your location.

How Do Applications Impact Laser Cut Staircase Panels Cost?

The end-use scenario—whether for industrial or architectural application—also plays a major role in pricing.

Industrial Applications

In industrial environments, panels are often used for:

- Walkways

- Safety barriers

- Stair treads and platforms

Here, the focus is on durability, anti-slip surfaces, and load-bearing strength. Laser cutting may be combined with punching or bending processes. Material cost is higher, and the design is typically simpler, but the finishing and reinforcement may raise the cost.

Architectural Applications

In contrast, architectural staircase panels prioritize aesthetic appeal, visual harmony, and interior/exterior integration. Common uses include:

- Stair railings

- Balustrades

- Decorative partitions

Materials such as brushed stainless steel or aluminum are popular. Intricate design and finishing significantly raise laser cut staircase panels cost in architectural settings.

Global Pricing Trends for Laser Cut Staircase Panels Cost

The cost can vary widely based on geographic location and manufacturing source. Below is a general pricing trend:

Working directly with manufacturers like Huijin Mesh in China allows buyers to reduce initial cost, but added logistics and import tax must be accounted for in the final budget.

How to Calculate Total Laser Cut Staircase Panels Cost for a Project?

To calculate total project cost, consider all components:

- Panel cost per unit × Quantity

- Design fee or setup cost (often $100–$300 for custom work)

- Shipping charges

- Customs/duties

- Installation and fitting

- Accessories and hardware

Example:

- You are installing 12 aluminum staircase panels for a residential project.

- Panel cost: $180 × 12 = $2,160

- Design setup: $200

- Powder coating: $50 × 12 = $600

- Shipping & duty: $350

- Total ≈ $3,310

Always ask for itemized quotations to verify hidden or extra fees.

What Mistakes to Avoid When Estimating Laser Cut Staircase Panels Cost?

Avoid these common pitfalls:

Ignoring Setup Fees

Some buyers mistakenly assume design setup is included. In reality, suppliers may charge a one-time CNC programming fee for custom patterns.

Underestimating Shipping Costs

Large metal panels are heavy and may require custom crating. Shipping 10 panels overseas can easily exceed $300–$500.

Overlooking Installation Complexity

Decorative panels might need custom brackets, alignment tools, or welding, all of which add time and labor costs.

Forgetting Compliance Requirements

In industrial projects, safety standards (e.g., OSHA, EN1090) must be met. Certification may incur added engineering or documentation fees.

How to Reduce Laser Cut Staircase Panels Cost Effectively?

Here are practical ways to manage costs without sacrificing quality:

Use Pre-Designed Patterns

Custom artwork adds programming cost. Opt for supplier-provided templates when possible.

Stick to Standard Sizes

Standard panel sizes like 1200mm × 800mm avoid waste and reduce setup complexity.

Choose Efficient Materials

If your project is indoors and not exposed to moisture, mild steel with powder coating is a cost-effective alternative to stainless steel.

Buy in Bulk

Even ordering 10–15 units instead of 5 can significantly drop the per-unit price.

Compare Local and Overseas Options

Domestic purchases offer quick delivery, while international sourcing may save cost if shipping is planned efficiently.

What to Ask Suppliers When Quoting Laser Cut Staircase Panels Cost?

Before placing an order, clarify these details:

- Is the panel cost all-inclusive (material, cutting, finishing)?

- Are there extra charges for design or customization?

- Can you provide installation drawings or mounting suggestions?

- What is the estimated lead time and delivery method?

- Is the finish weather-resistant or suitable for indoor use?

- Are there volume discounts?

A transparent discussion ensures you understand the complete laser cut staircase panels cost upfront.

Conclusion: What Should You Expect When Planning for Laser Cut Staircase Panels Cost?

The cost of laser cut staircase panels is influenced by multiple dynamic factors: material type, size, design, finish, and purpose. By understanding each cost component and planning strategically, buyers can control their budget without compromising on quality or design intent.

Whether your project is industrial, architectural, or decorative, the right supplier and clear specifications can streamline costs. Taking time to gather detailed quotations and ask the right questions ensures your project is on track, both financially and structurally.

Comments