Germany, one of the largest and most advanced economies in Europe, continues to hold a prominent position in the global ceramic machinery market. As industries shift toward sustainable and energy-efficient practices, the Germany Ceramic Machinery Market has seen substantial growth, driven by technological advancements and increased demand for high-quality ceramic products. This article delves into the Germany ceramic machinery market, examining its current trends, technological innovations, and the role of sustainable technologies in shaping the future of the industry.

Overview of the Germany Ceramic Machinery Market

Germany’s ceramic industry is highly developed, encompassing a broad range of products, from traditional ceramic goods like tiles, bricks, and sanitary ware to innovative high-tech ceramic applications in electronics, automotive, and energy sectors. The ceramic machinery market in Germany serves these industries by providing state-of-the-art equipment for manufacturing, processing, and finishing ceramic products. With a rich industrial history, the country is home to several global ceramic machinery manufacturers, offering advanced and custom-designed machinery solutions.

The demand for ceramic machinery in Germany is not just driven by the local production capacity but also by the export of high-tech ceramics to other countries. This makes the market crucial for both domestic and international markets, with several global players looking to Germany for high-quality machines that enhance productivity and maintain competitive advantages.

Key Drivers of the Ceramic Machinery Market in Germany

Several factors are driving the growth of the ceramic machinery market in Germany. These include:

1. Technological Advancements

Germany has been at the forefront of adopting advanced technologies in the manufacturing process. The integration of Industry 4.0 concepts, automation, and artificial intelligence into ceramic machinery is reshaping production efficiency and output quality. The adoption of robotics, sensors, and data analytics in ceramic production lines allows for more precise control over processes and a significant reduction in human errors.

2. Rising Demand for High-Quality Ceramics

The demand for high-quality ceramic products, particularly in the construction and automotive sectors, is rising in Germany. This has led to a shift in the focus of ceramic machinery manufacturers towards producing more efficient, high-performance machines that can meet stringent quality standards.

3. Government Regulations and Initiatives

The German government has been actively promoting sustainability and energy efficiency in manufacturing sectors. Subsidies, incentives, and support programs are helping ceramic machinery manufacturers adopt cleaner technologies and reduce their environmental footprint. Germany’s commitment to reducing carbon emissions also influences the need for sustainable production practices in the ceramics industry.

4. Increase in Export Markets

As one of the largest exporters of ceramic products globally, Germany’s ceramic machinery market benefits from high export demand. With industries in Asia, the Middle East, and Europe seeking advanced machinery to improve their own ceramic production capabilities, Germany remains a key player in global ceramic machinery supply chains.

Sustainable Technologies in Ceramic Machinery

Sustainability has become a key focus in Germany’s ceramic machinery sector. The growing emphasis on energy efficiency, reduced waste, and lower carbon emissions has prompted machinery manufacturers to adopt sustainable technologies. Below are some of the key sustainable practices and technologies being implemented in the industry.

1. Energy-Efficient Kilns

One of the most energy-consuming processes in ceramic production is the firing process, which involves heating the ceramic material in kilns. Traditional kilns are notorious for high energy consumption, which not only increases production costs but also contributes to environmental pollution. To address this, Germany has seen the development of energy-efficient kilns that use advanced heat recovery systems, reducing energy waste. These kilns are often equipped with innovative technology that allows for better temperature control, resulting in more consistent product quality and less energy usage.

2. Use of Renewable Energy

Ceramic machinery manufacturers in Germany are increasingly turning to renewable energy sources such as solar, wind, and hydropower to meet their production needs. By transitioning to clean energy, companies can significantly reduce their carbon footprint and lower operational costs in the long term. Many of these manufacturers are also designing machines that are compatible with renewable energy sources, providing greater flexibility in energy use and contributing to more sustainable production processes.

3. Waste Reduction Technologies

Waste management is a critical issue in the ceramic manufacturing industry, as it generates significant amounts of scrap materials. However, advancements in waste reduction technologies, such as closed-loop systems and recycling initiatives, are helping to minimize this waste. Manufacturers are now able to recycle ceramic waste and reuse it in the production process, reducing the need for raw materials and decreasing the environmental impact of production. Additionally, new machinery designs focus on improving material utilization, ensuring that every part of the material is used efficiently.

4. Water Recycling Systems

Water usage in ceramic manufacturing is another area where sustainable practices are being implemented. Water is necessary in various stages of ceramic production, but its excessive use can lead to environmental concerns, particularly in areas where water is scarce. Advanced ceramic machinery now includes water recycling systems that allow for the filtration and reuse of water, significantly reducing the amount of water required during production. These systems ensure that water consumption is minimized, making the production process more sustainable.

5. Reduction of Emissions

Germany is known for its stringent environmental regulations, and the ceramic industry is no exception. Machinery manufacturers are incorporating technologies that reduce the emission of harmful gases and particulate matter during the manufacturing process. For example, advanced filtration systems and electrostatic precipitators are being used to trap pollutants from kiln emissions. Additionally, technologies that minimize the use of volatile organic compounds (VOCs) in the glazing process are being widely adopted. This shift towards cleaner production methods aligns with Germany’s broader environmental goals.

Innovations in Ceramic Machinery

Apart from sustainability, technological innovations in the ceramic machinery sector are improving productivity and product quality. These innovations are setting the stage for the future of ceramic manufacturing in Germany.

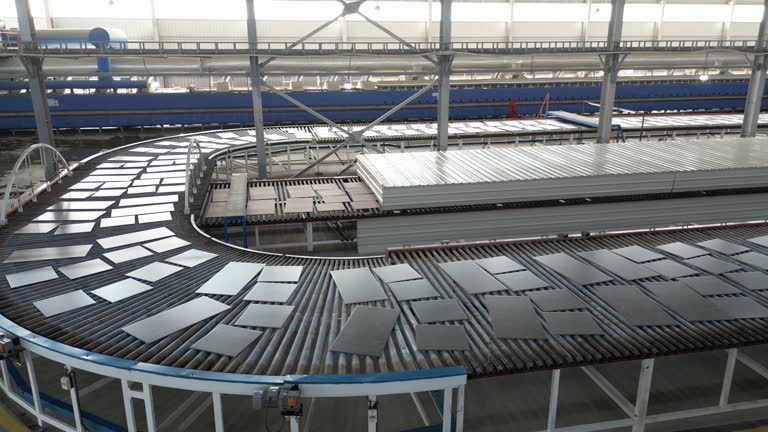

1. Automation and Robotics

Automation is one of the most significant trends shaping the ceramic machinery market. The integration of robotics in the manufacturing process allows for greater precision, increased speed, and reduced labor costs. Robots are now being used to automate the handling, packing, and even inspection of ceramic products. This automation not only boosts production efficiency but also ensures higher levels of product consistency.

2. 3D Printing for Ceramics

Another exciting innovation is the use of 3D printing technology in ceramic production. 3D printing allows for the creation of intricate designs and customized ceramic products with high accuracy. This technology is particularly useful in industries such as medical devices, aerospace, and automotive, where precision and customization are critical. With Germany's strong emphasis on technological advancement, 3D printing is poised to revolutionize the ceramic industry, offering new opportunities for both manufacturers and consumers.

3. Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning are becoming integral components in the ceramic machinery industry. These technologies are being employed to enhance the monitoring and control of production lines, predict maintenance needs, and optimize machine performance. AI-powered systems can analyze large amounts of data from the production process to identify potential issues before they lead to breakdowns, reducing downtime and improving overall efficiency.

Challenges and Future Outlook

While the Germany ceramic machinery market is growing rapidly, several challenges remain. These include the high initial cost of implementing advanced technologies, the complexity of integrating new systems into existing production lines, and the need for skilled labor to operate sophisticated machinery. However, the long-term benefits, including improved efficiency, reduced environmental impact, and enhanced product quality, outweigh these challenges.

The future of the ceramic machinery market in Germany looks promising, with continued investment in sustainable technologies, automation, and innovative machinery solutions. As industries worldwide focus more on sustainability, Germany is well-positioned to remain a leader in the global ceramic machinery market, driving innovation and setting standards for other countries to follow.

Conclusion

The Germany ceramic machinery market is witnessing significant transformation, driven by technological innovations and a strong focus on sustainability. From energy-efficient kilns and water recycling systems to automation and AI integration, Germany’s ceramic machinery manufacturers are at the forefront of advancing sustainable and efficient production practices. These innovations not only help reduce the environmental footprint of the industry but also enhance the quality and efficiency of ceramic products. With a commitment to sustainable technologies and continuous investment in research and development, Germany is poised to remain a global leader in the ceramic machinery market for years to come.

Comments